A precision dressing method for ball-end grinding wheel based on double-arc fitting error compensation

A fitting error and double-arc technology, which is applied to the parts of grinding machine tools, abrasive surface adjustment devices, metal processing equipment, etc., can solve the problem of high surface accuracy and dimensional accuracy, difficulty in obtaining, high cost of ball-end grinding wheel dressing, etc. problems, to achieve the effect of small surface roughness, low cost and high dressing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

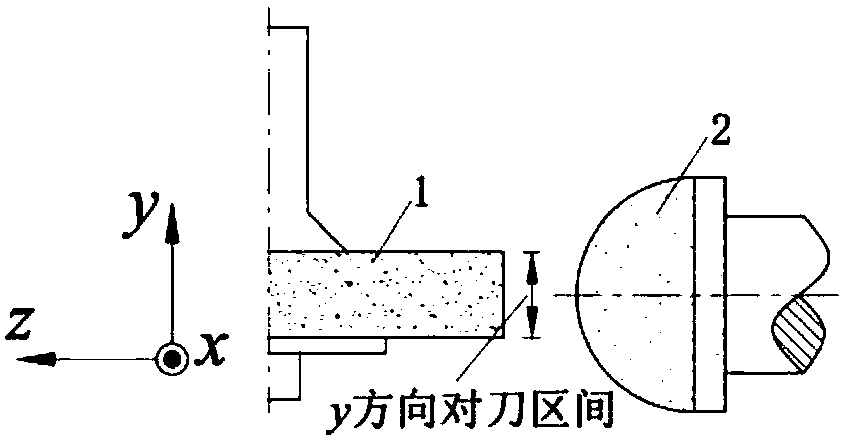

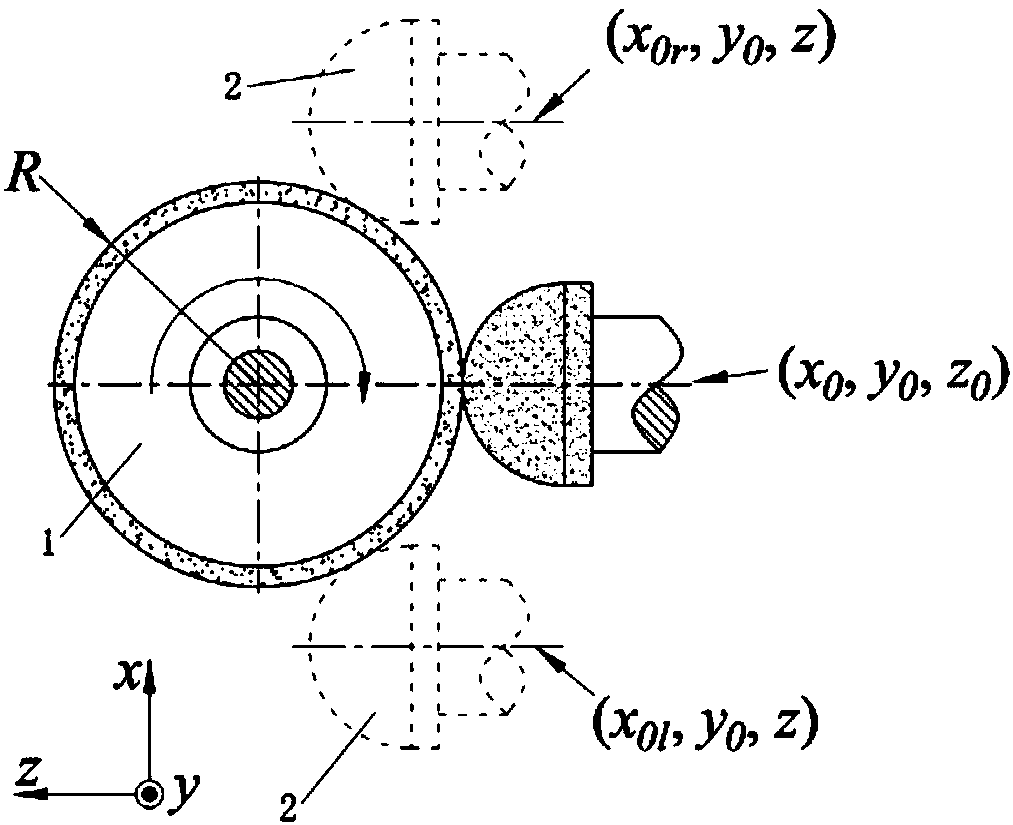

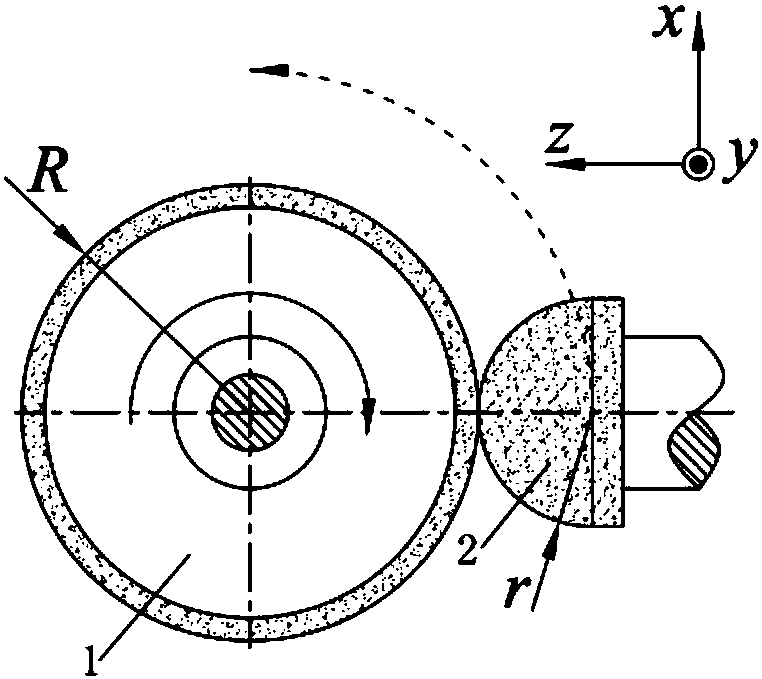

[0028] Specific implementation mode 1: A kind of ball-end grinding wheel precision dressing method based on double-arc fitting error compensation in this implementation mode is specifically carried out according to the following steps:

[0029] Step 1. Set the direction parallel to the axis of rotation of the main shaft of the machine tool as the z-axis, and the axis perpendicular to the z-axis on the horizontal plane of the machine tool as the x-axis, thereby establishing a coordinate system xyz; install the dressing wheel and the laser micrometer on the x-axis of the machine tool On the axis, the rotation axis of the dressing wheel is parallel to the y-axis of the machine tool, and the laser beam of the laser micrometer is parallel to the z-axis of the machine tool; the ball-end grinding wheel is installed on the z-axis, and the rotation axis of the ball-end grinding wheel is parallel to the z-axis; among them, The x linear axis and the z linear axis can be linked to realize ...

specific Embodiment approach 2

[0038] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the dressing wheel in Step 1 is a disc-shaped electroplated diamond grinding wheel, and the particle size can be 90-300 μm. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0039] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the ball-end grinding wheel described in Step 1 is a resin-bonded diamond grinding wheel with a particle size of 1-60 μm. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com