Stirring equipment for stirring coal gangue brick mud

A technology for mixing equipment and coal gangue, which is applied in the field of mixing equipment for mixing coal gangue brick mud, which can solve the problems of a large amount of finished products, low mixing efficiency, and unmixed particles, so as to improve utilization efficiency, eliminate particles and air bubbles, and improve uniformity. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

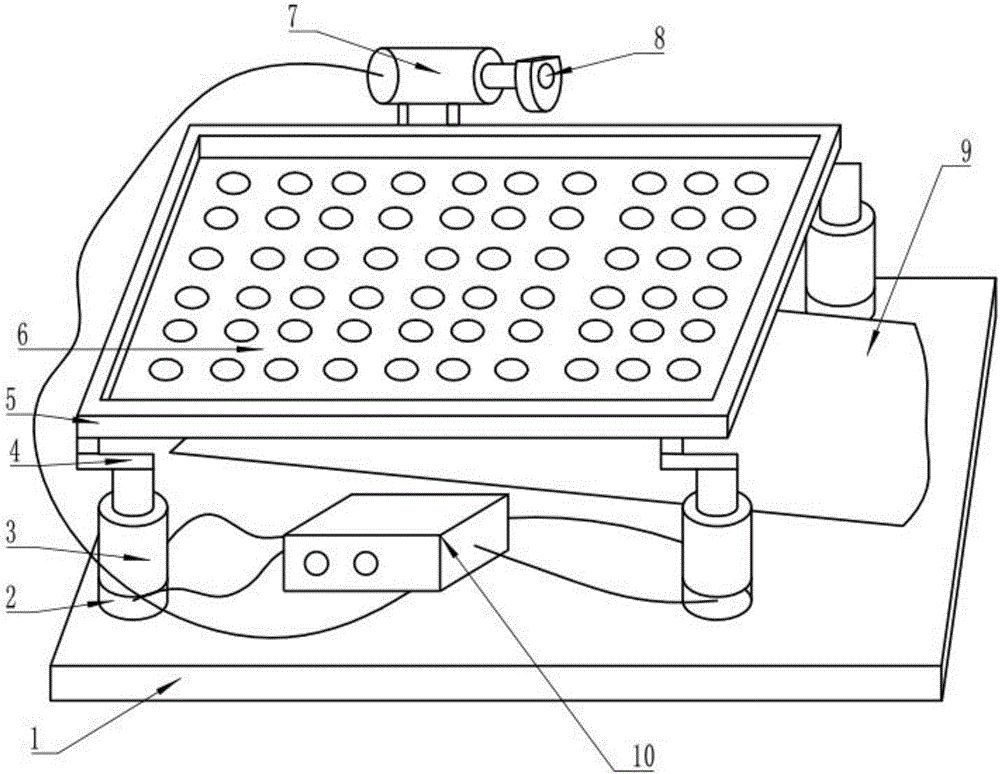

[0020] Such as figure 1 As shown, a mixing equipment for mixing coal gangue brick mud mainly consists of a machine 1, a pressure sensor 2, a rotating motor 3, a double heart wheel 4, a sieve plate 5, a screen 6, a vibration motor 7, and an eccentric wheel 8 , control circuit 10; there are four pressure sensors 2, rotating motors 3 and double heart wheels 4, the four pressure sensors 2 are respectively arranged on the machine platform 1, and the four rotating motors 3 are respectively arranged on the four pressure sensors 2 , the rotating shafts of the four rotating motors 3 are respectively connected to one axis of the four double-heart wheels 4, and the other axes of the four double-heart wheels 4 are respectively connected to the four corners of the sieve tray 5; the sieve tray 5 is a cuboid frame type structure, the screen 6 is arranged in the sieve tray 5; the vibrating motor 7 is arranged on the sieve tray 5, and the rotating shaft of the vibrating motor 7 is connected wi...

Embodiment 2

[0024] On the basis of Example 1, this embodiment discloses a preferred structure of a mixing device for mixing coal gangue brick mud, such as figure 1 As shown, the machine platform 1 is a cuboid structure, and the material of the machine platform 1 is cast iron. Cast iron is cheap and dense enough to keep equipment functioning properly during vibrations.

[0025] Further, the double-heart wheel 4 is elliptical, and two holes are opened on the major axis at the same distance from the axis. This converts the rotation into a shake.

[0026] Further, the screen 6 is sheet-shaped, and a plurality of small holes are uniformly arranged on the screen 6 , and the screen 6 is connected with the sieve tray 5 through buckles. The buckle connection is easy to disassemble, and the screen with different aperture sizes can be replaced, or the screen is broken, which is easy to maintain. It improves the function while reducing the maintenance cost and improving the economic benefits.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com