Porous biological enzyme processor

A biological enzyme and processor technology, applied in water/sewage multi-stage treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems that cannot meet the requirements of organic wastewater treatment, and improve biochemical performance, improve catalytic activity, and prolong adsorption life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

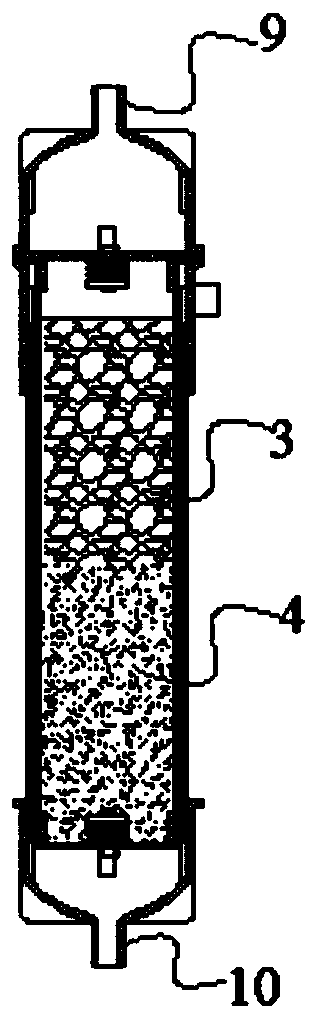

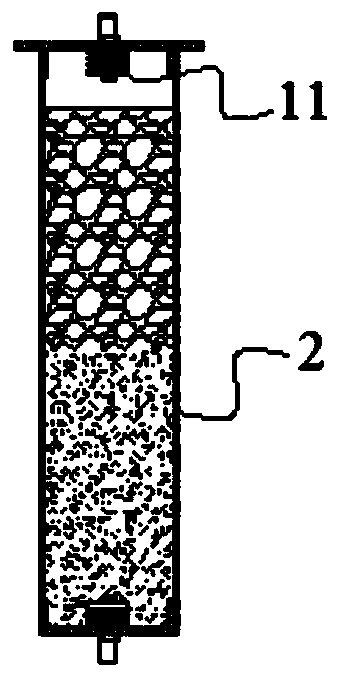

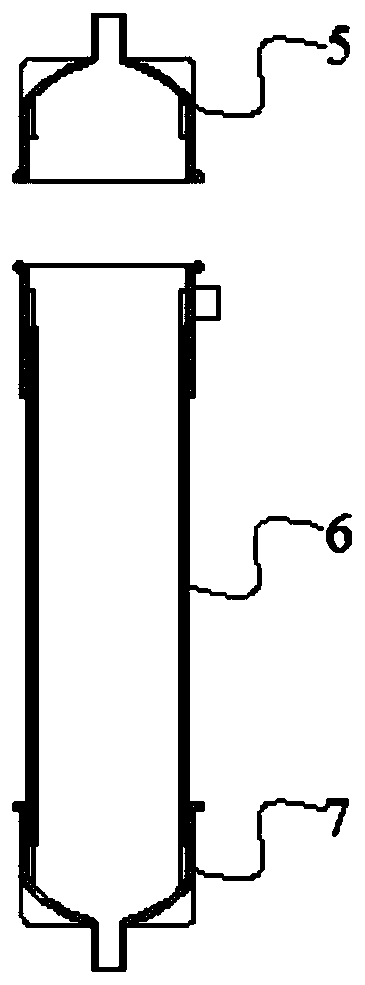

[0031] Embodiment: a kind of porous biological enzyme processor, such as Figure 1-4 As shown, the present invention includes a housing 1 and a porous biological enzyme filter core 2 positioned in the housing 1, the porous biological enzyme filter core 2 is filled with a porous biological enzyme filler 3, and the porous biological enzyme filler 3 is combined with iron , carbon material, leavening agent and protease and a microporous structure full of micropores.

[0032] The porous bio-enzyme filler 3 is a microporous structure formed by mixing iron powder, carbon material powder and leavening agent into natural pottery clay, sintering and cooling in protease solution. The iron powder used in the present invention is preferably oxidized iron powder, the leavening agent is preferably sodium bicarbonate, and the carbon material powder is preferably graphite powder, but not limited thereto. For example, as a modification and replacement of the present invention, the carbon mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com