Preparation method for producing dialkyl chlorophosphate reagent from polyethylene glycol

A technology of dihydrocarbyl chlorophosphate and polyethylene glycol, which is applied in the fields of chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., and can solve the problem of long reaction time, incomplete reaction, and difficult product Purification and other issues, to achieve the effect of short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

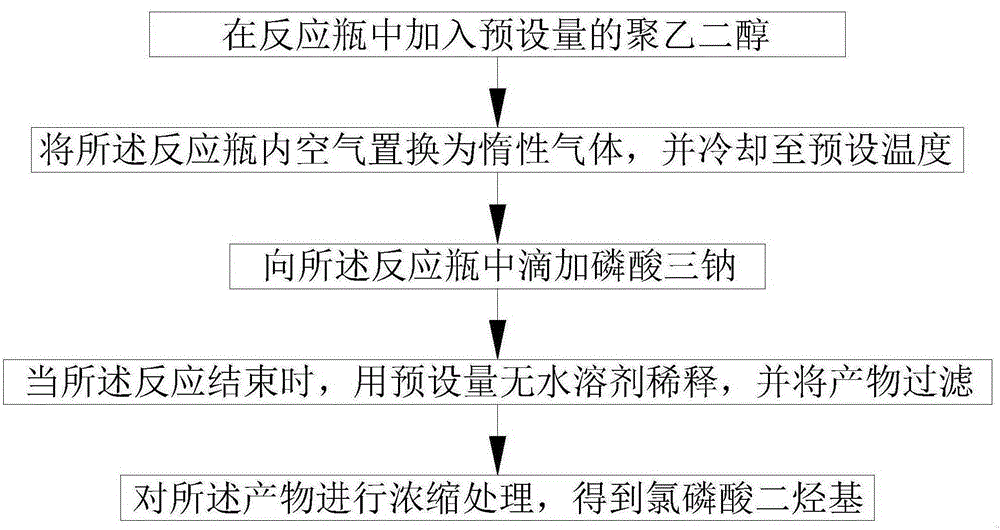

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: Preferably in the present invention, the polyethylene glycol accounts for 50% of the ingredients; the trisodium phosphate accounts for 30% of the ingredients; and the anhydrous solvent accounts for 20% of the ingredients.

Embodiment 2

[0040] Embodiment 2: Preferably in the present invention, the polyethylene glycol accounts for 55%; the trisodium phosphate accounts for 25%; and the anhydrous solvent accounts for 20%.

Embodiment 3

[0041] Embodiment 3: Preferably in the present invention, the polyethylene glycol accounts for 60% of the ingredients; the trisodium phosphate accounts for 20% of the ingredients; and the anhydrous solvent accounts for 20% of the ingredients.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com