Method for improving hydrogen production of chlamydomonas

A technology of Chlamydomonas and Rhinoceros is applied in the field of microorganisms, which can solve problems such as high cost, and achieve the effect of solving contradictions and broadening the scope of symbiotic objects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

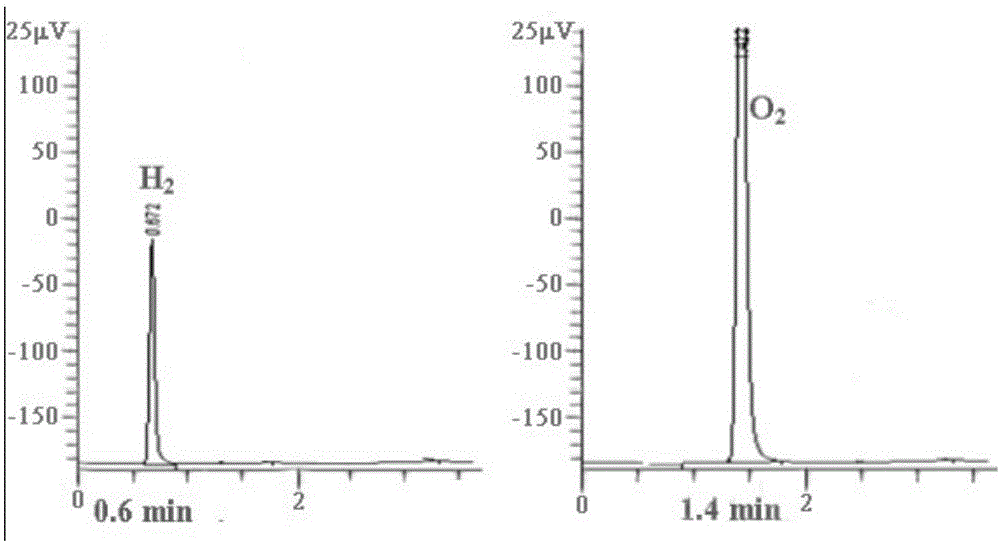

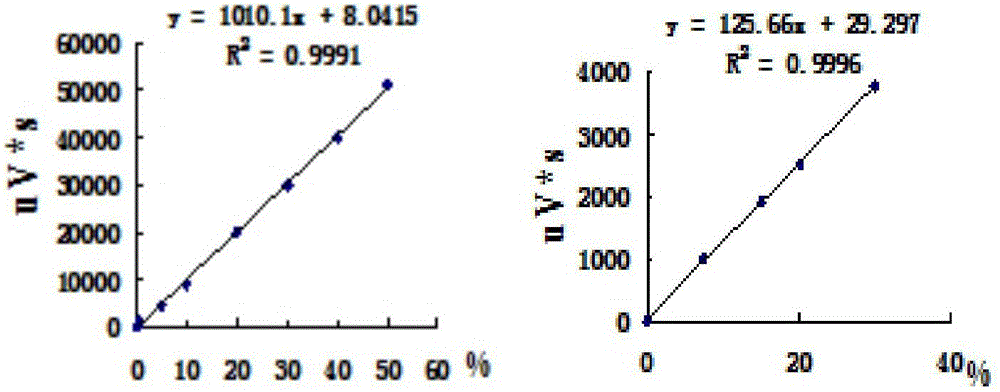

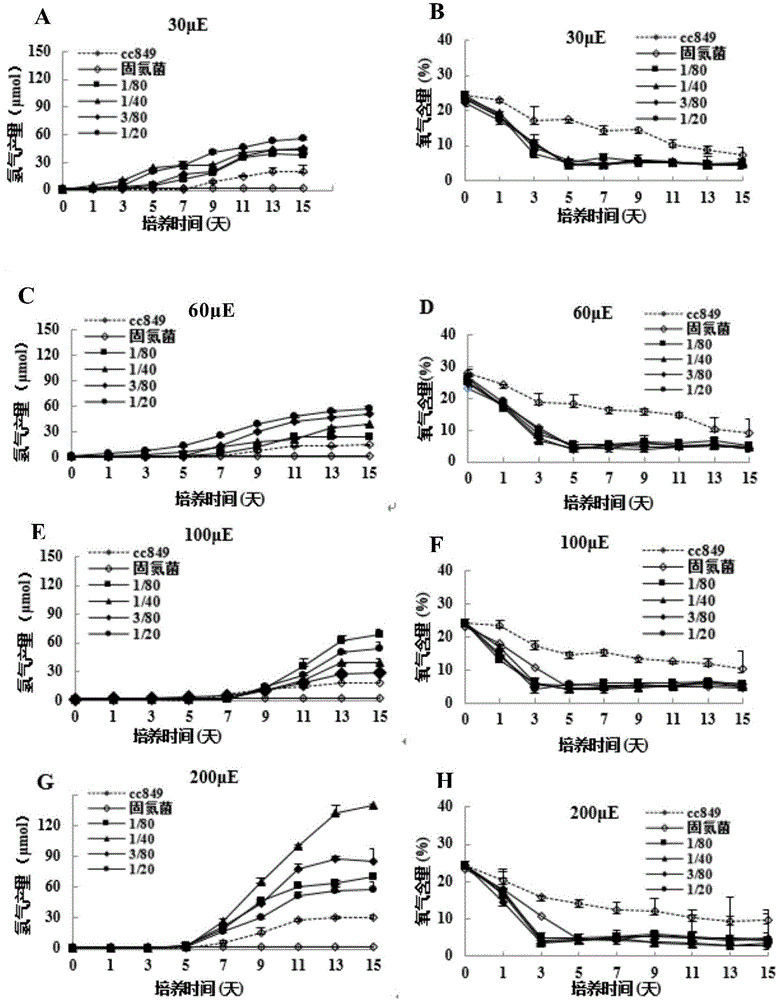

[0081] The hydrogen production cultivation of embodiment 1 algal bacteria

[0082] Chlamydomonas was cultured to saturation phase (OD 750 About 3.0), centrifuged at 5000rpm for 5 minutes with a centrifuge, removed the supernatant, added an appropriate amount of sulfur-deficient medium to resuspend 3 times, to completely remove the sulfur in the original medium. The Chlamydomonas treated with sulfur deficiency was transferred to a 60ml hydrogen-producing culture bottle according to the chlorophyll concentration of 0.5mg / L, and the volume was adjusted to 45ml with sulfur-deficiency medium. The nitrogen-fixing bacteria cultured to the logarithmic phase (OD 600 =1) According to the volume ratio of bacteria and algae 1:80, 1:40, 3:80, 1:20 respectively into the hydrogen-producing bottle that has been added with Chlamydomonas, and finally seal the bottle mouth with a rubber stopper. The culture system with only Chlamydomonas and nitrogen-fixing bacteria was used as the control g...

Embodiment 2

[0099] Example 2 Contribution of Chlamydomonas reinhardtii and nitrogen-fixing bacteria to hydrogen production in co-culture system

[0100] In order to understand the contribution of algae and bacteria to the improvement of hydrogen production in the mixed co-culture system of Chlamydomonas and nitrogen-fixing bacteria, the pure Chlamydomonas culture system, the pure nitrogen-fixing bacteria culture system, and the Chlamydomonas-diazotobacter co-cultivation system under the optimal hydrogen production conditions were combined. The culture system and optimal mixing ratio of Chlamydomonas lysate (that is, algae treated with liquid nitrogen freeze-thawing)-diazotobacter co-culture system (total of 4 different culture systems) were continuously measured for hydrogen after 24 hours of darkness. The results are as follows Figure 5 shown.

[0101] It can be seen from the results that the pure nitrogen-fixing bacteria culture system and the Chlamydomonas lysate-diazotobacter co-cu...

Embodiment 3

[0105] Growth status and distribution pattern of Chlamydomonas and nitrogen-fixing bacteria in the co-cultivation system of embodiment 3 algae

[0106] 1. In order to detect the growth of Chlamydomonas after co-cultivation with nitrogen-fixing bacteria, the co-cultivation conditions with the best hydrogen production were detected in the normal TAP medium and the hydrogen-producing TAP-S medium respectively. The growth of the following two algae.

[0107] The co-cultivation operation of algal bacteria under normal culture conditions is as follows: culture nitrogen-fixing bacteria in logarithmic phase (OD600 is about 1.0), centrifuge at 5000rpm for 5 minutes, remove the supernatant, and resuspend three times with the same volume of TAP to completely remove nitrogen-fixing bacteria For the culture medium, the resuspended nitrogen-fixing bacteria are mixed with Chlamydomonas according to the ratio of bacteria and algae under the optimal hydrogen production conditions, and added ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com