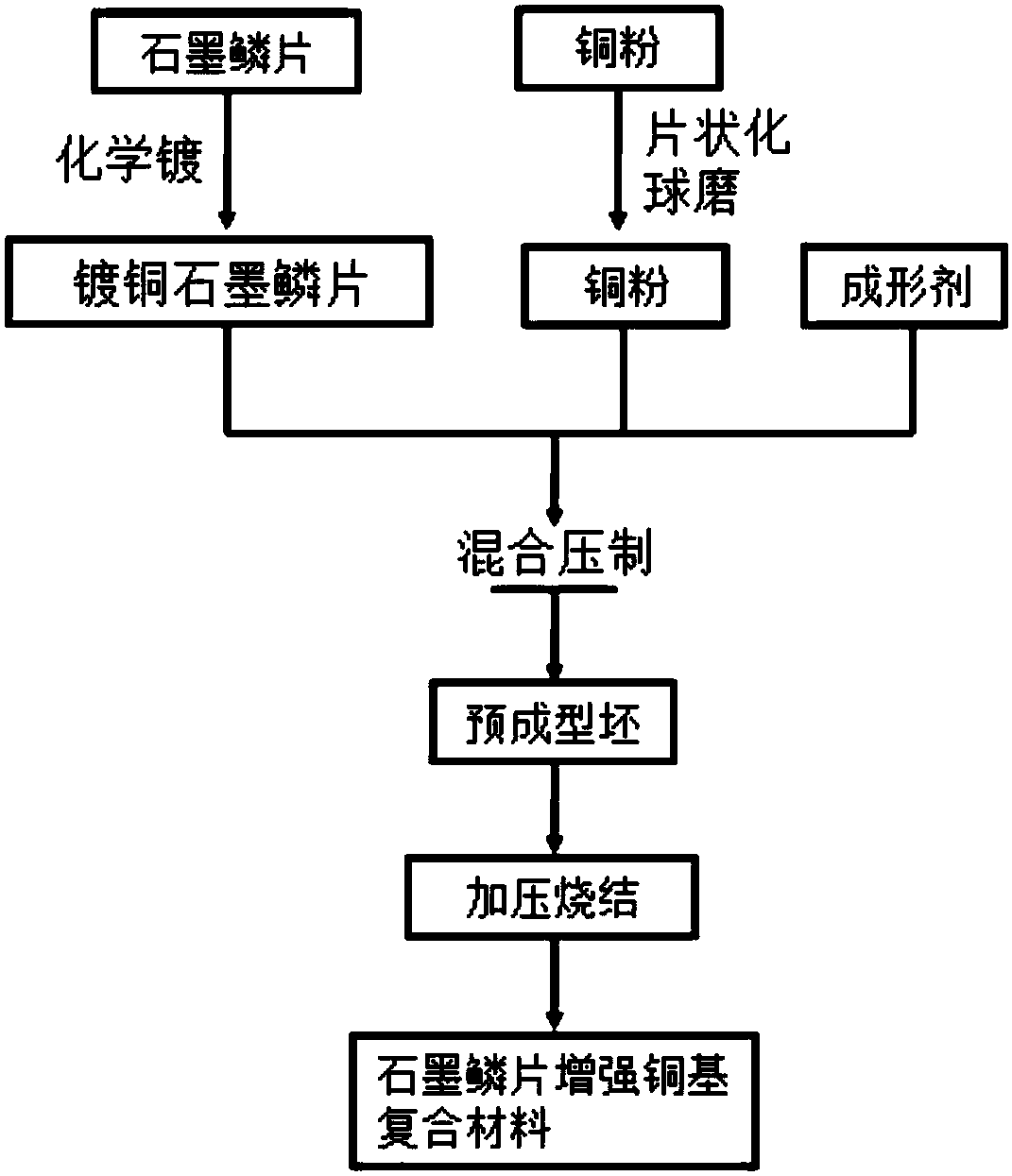

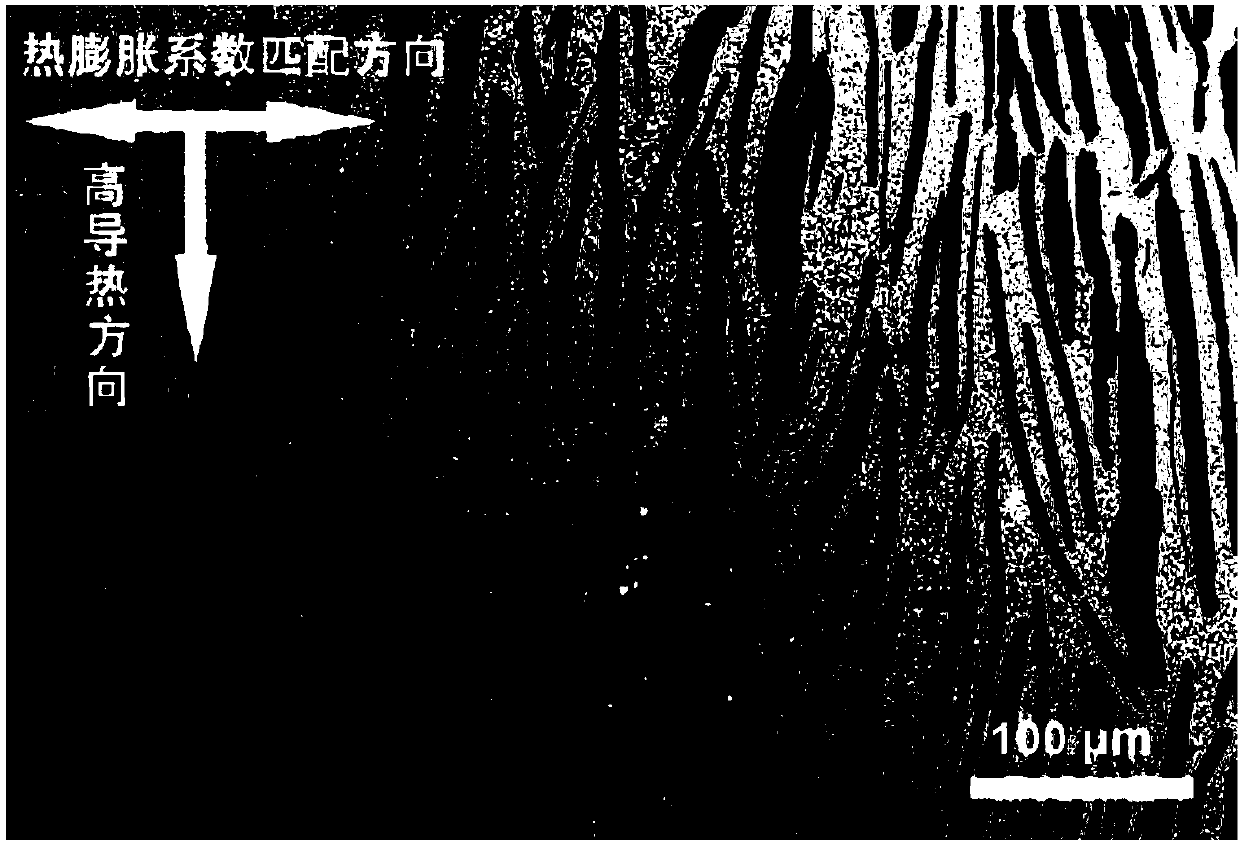

A graphite flake/copper composite material for vertically oriented heat dissipation and its preparation method

A technology of graphite flakes and composite materials, which is applied in the direction of semiconductor/solid-state device parts, electrical components, circuits, etc., can solve heat dissipation and other problems, and achieve the effects of good directional thermal conductivity, low raw material cost, and easy cutting and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030]In this embodiment, the graphite flakes have a thickness of 10 μm and an average diameter of 200 μm. Firstly, electroless copper plating treatment is carried out on the surface of the graphite flakes: put the graphite flakes into a NaOH solution with a mass fraction of 20%, rinse and stir for 15 minutes, let stand and pour off the solution, and rinse with ionized water until neutral. Put the washed graphite flakes into 20ml / L HCl+20g / L SnCl 2 Sensitization reaction in the solution: Stir vigorously for more than 15 minutes until the solution turns blue-gray, let it stand and pour off the excess solution. Activation stage: Add 20ml / L HCl+0.5g / L PdCl to the sensitized graphite flakes 2 The solution was vigorously stirred for more than 15 minutes, and the reaction was complete when the solution turned light brown. Pour the sensitized and activated graphite flakes into the copper plating bath, and the treatment amount of graphite is 1g / L. The formula of the plating solutio...

Embodiment 2

[0035] In this embodiment, the graphite flakes have a thickness of 10 μm and an average diameter of 150 μm. Firstly, electroless copper plating treatment is performed on the surface of the graphite flakes: the graphite flakes are put into a 20% NaOH solution by mass fraction, rinsed and stirred for 15 minutes, left to stand and poured off the solution, and rinsed with ionized water until neutral. Put the washed graphite flakes into 20ml / L HCl+20g / L SnCl 2 Sensitization reaction in the solution: Stir vigorously for more than 15 minutes until the solution turns blue-gray, let it stand and pour off the excess solution. Activation stage: Add 20ml / L HCl+0.5g / L PdCl to the sensitized graphite flakes 2 The solution was vigorously stirred for more than 15 minutes, and the reaction was complete when the solution turned light brown. Pour the sensitized and activated graphite flakes into the copper plating bath, and the treatment amount of graphite is 1g / L. The formula of the plating ...

Embodiment 3

[0040] In this example, graphite flakes with a thickness of 5 μm and an average diameter of about 70 μm and a thickness of 10 μm and an average diameter of about 150 μm were selected as the reinforcing phase by mixing them at a volume ratio of 1:1. Electroless copper plating on the surface of the graphite flakes: put the graphite flakes into a NaOH solution with a mass fraction of 20%, rinse and stir for 15 minutes, let stand and pour off the solution, and rinse with ionized water until neutral. Put the washed graphite flakes into 20ml / L HCl+20g / L SnCl 2 Sensitization reaction in the solution: Stir vigorously for more than 15 minutes until the solution turns blue-gray, let it stand and pour off the excess solution. Activation stage: Add 20ml / L HCl+0.5g / L PdCl to the sensitized graphite flakes 2 The solution was vigorously stirred for more than 15 minutes, and the reaction was complete when the solution turned light brown. Pour the sensitized and activated graphite flakes int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com