Determination and adjustment method for high-slip motor-driven beam-pumping unit balance

A beam pumping unit and the technology of the determination method are applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., and can solve problems such as low rated efficiency of high-slip motors, calculation errors, and difficult solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

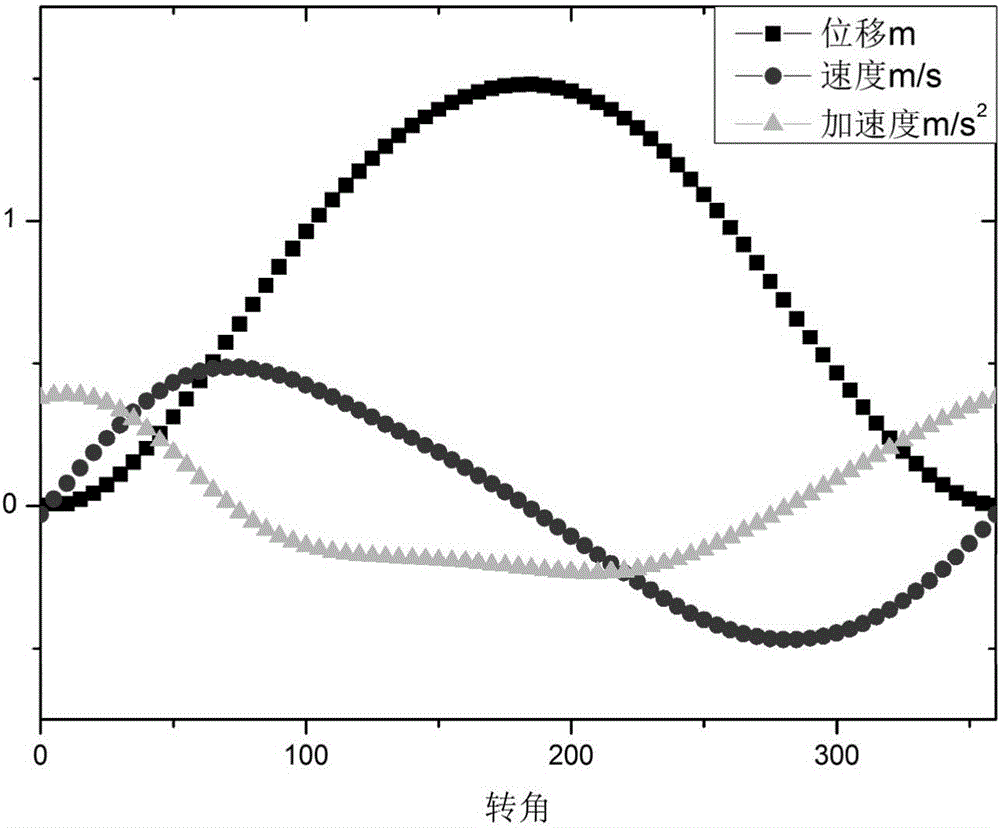

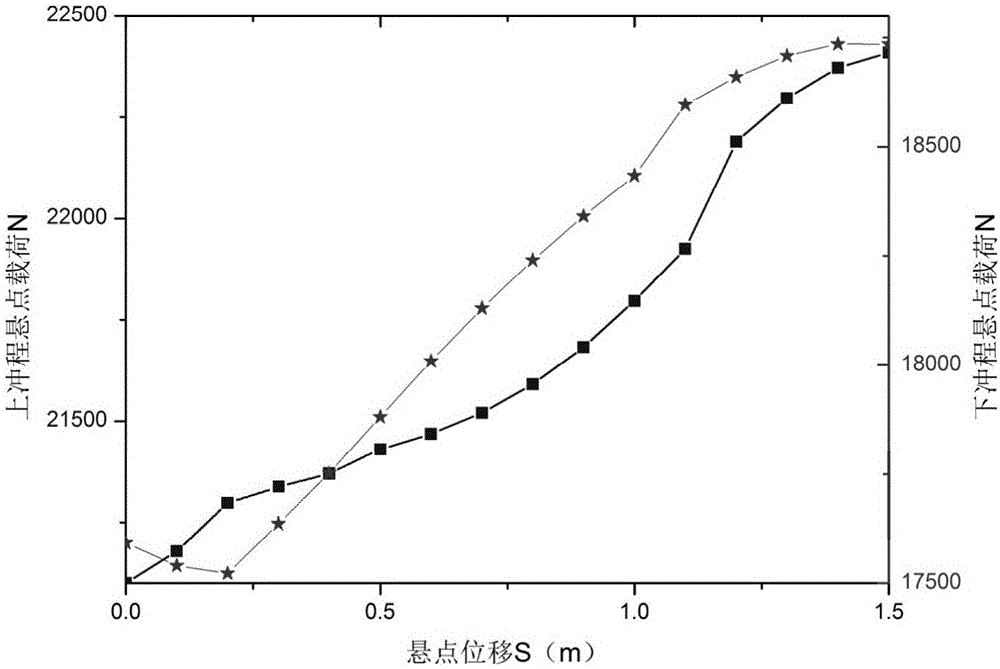

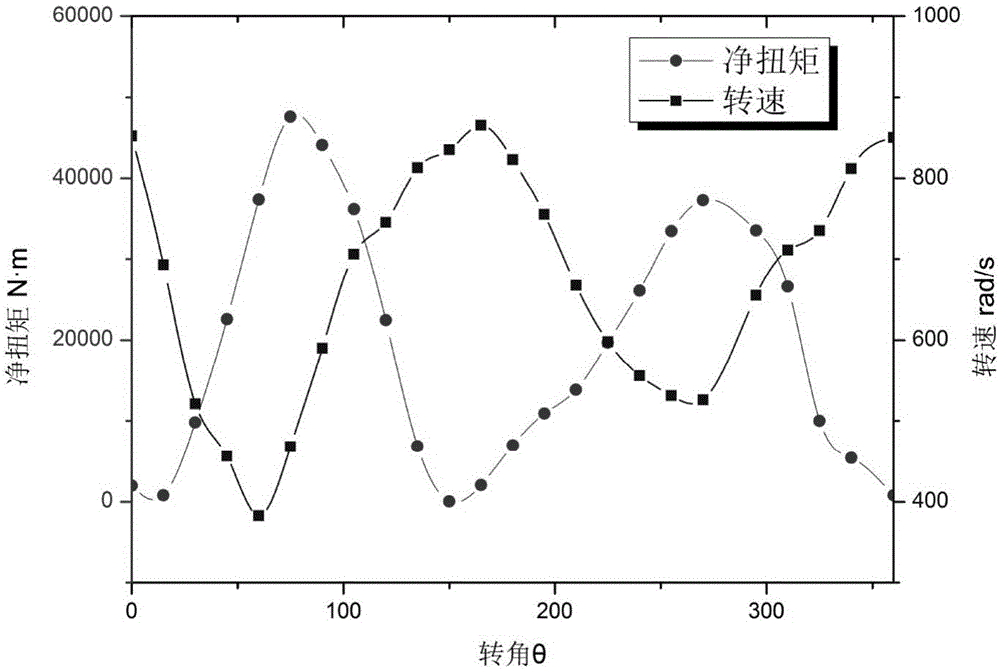

[0141] According to the existing three balance judgment criteria and the existing balance judgment method, based on the working principle of the beam pumping unit, the balance judgment is analyzed when the pumping unit is running at variable speed, such as when a high-slip motor is driven. The problem. Based on this problem, the crank speed of the pumping unit is calculated by using the vector control principle of the motor and the flux linkage observation method of the motor speed, and its change law is obtained, so that the coupling relationship between the crank motion equation and the wave equation of the sucker rod string is decoupled. The kinematics and dynamics of the suspension point of the pumping unit are analyzed, the velocity, acceleration, displacement and load of the suspension point of the pumping unit are calculated, the crank torque is calculated, and the balance judgment of the beam is carried out by using the torque curve.

[0142]Taking the CYJW10-3-37HY ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com