Integral sealing scraper for camshaft phase machine of vehicle engine VVT system

A technology for automobile engines and camshafts, which is applied to the sealing device of the engine, engine components, machines/engines, etc. It can solve the difficulty of monitoring scrapers and shrapnel, missed or wrong installation of scrapers and shrapnel, and increase parts manufacturing Cost and other issues, to achieve the effect of improving product quality control, simplifying structure and precision, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

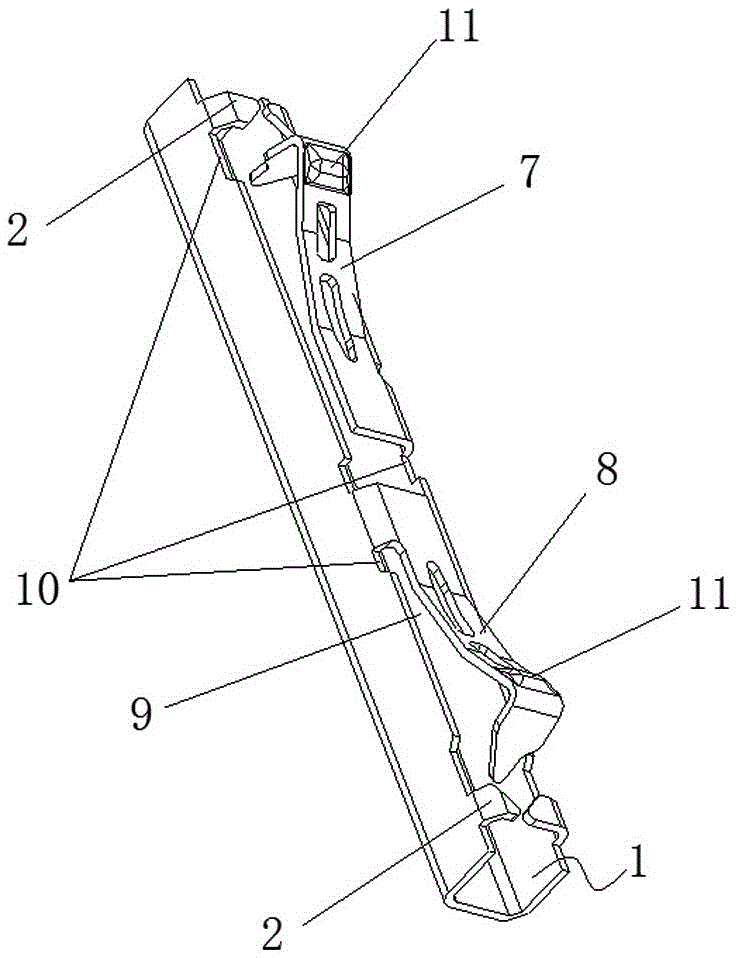

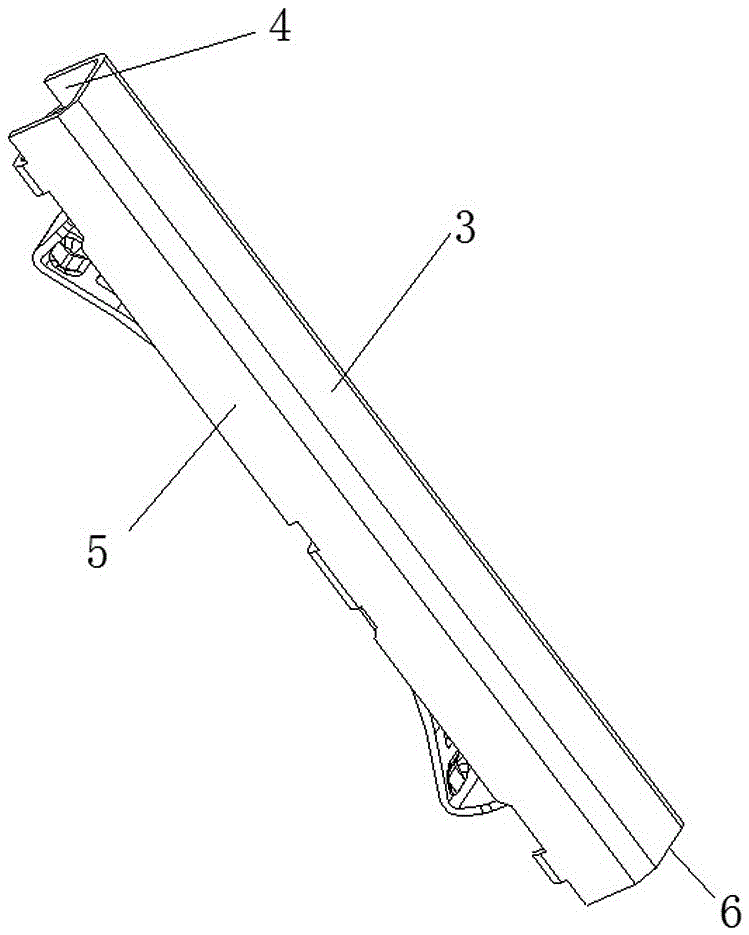

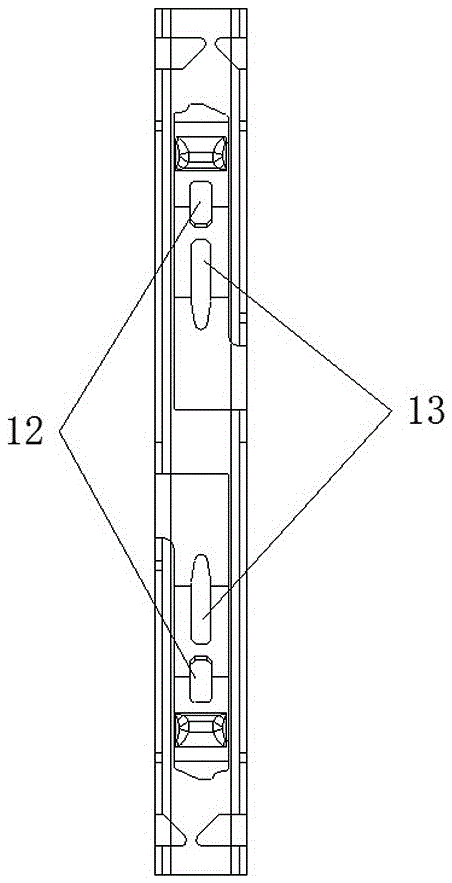

[0023] See Figure 1 to Figure 3 , the present invention is an integral sealing scraper for a camshaft phaser of an automobile engine VVT system, which has a scraper 1; The sealing surface 5 and the sealing surface 6 at the upper and lower ends are integrally set in a U shape. The two sides of the U-shaped opening of the scraper 1 are bent to form an upper elastic piece 7 and a lower elastic piece 8 with a central symmetry and a linear increase in elastic force; the upper elastic piece 7 and the lower elastic piece 8 are formed. The shrapnel 8 is provided with a small window gap for improving the stability of the phaser; the upper shrapnel 7 and the lower shrapnel 8 are both formed by a straight line parallel to the main sealing surface 3, near the center of the scraper 1 and low near the end face of the scraper 1. The arc line segment is integrally formed with the bending segment that is bent toward the main sealing surface 3 through the transition of the fillet.

[0024] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com