Wire-pipe type diesel vehicle tail gas particle trap based on corona discharge

A particle trap and corona discharge technology, which is applied in the direction of exhaust devices, machines/engines, noise reduction devices, etc., can solve environmental and human health hazards and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

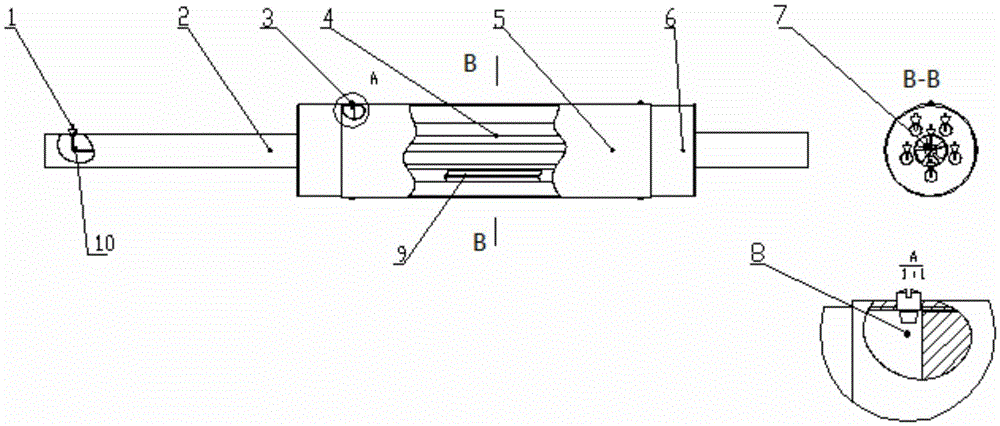

[0015] The reference signs in the accompanying drawings of the specification include: insulating tapered plug 1, charging tube 2, screw 3, dust collecting tube 4, sealed shell 5, exhaust gas outlet 6, ceramic support disc 7, ceramic disc 8, dust collecting electrode Line 9, charged electrode line 10.

[0016] The working process of the line tube type diesel vehicle exhaust particulate filter based on corona discharge: the diesel vehicle exhaust enters from the inlet of the charging tube 2, and after the PM is fully charged and condensed under the condition of pulsed corona discharge, it is charged The particles enter the dust collection pipe 4; under the action of the DC electric field force, the charged particles are collected on the inner wall of the dust collection pipe 4, and the purified gas is discharged into the atmosphere through the tail gas outlet 6. The sealed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com