Automobile engine turbocharger bent connector and production technology thereof

A technology for turbochargers and automobile engines, which is applied to engine components, machines/engines, manufacturing tools, etc., and can solve the problems of complicated joint manufacturing process, pipe blockage, and poor connection between parts and parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

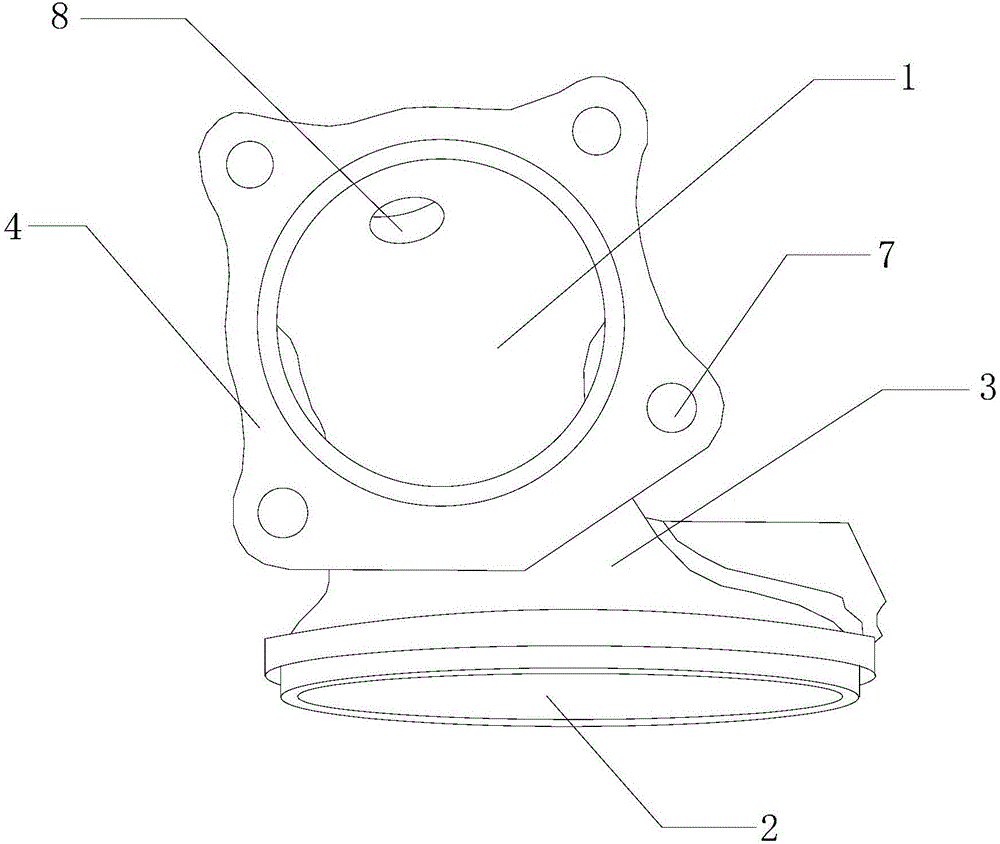

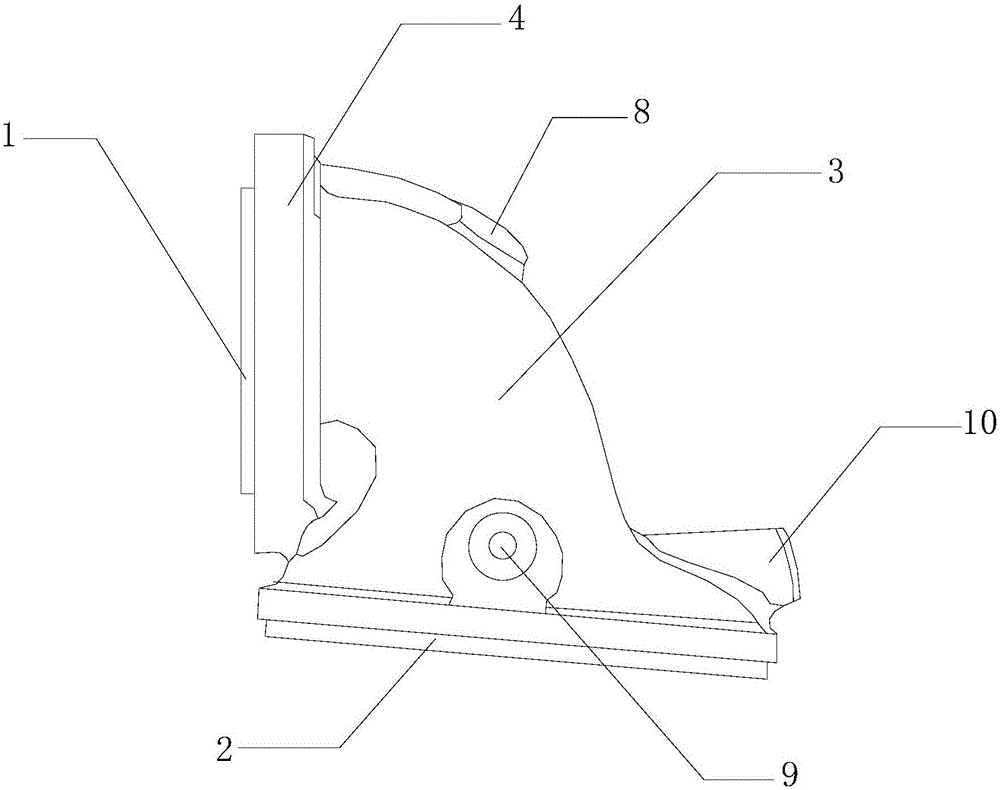

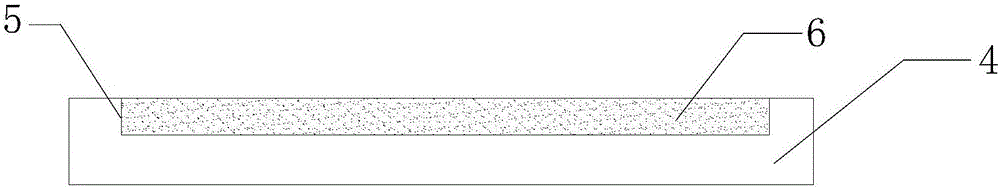

Embodiment 1

[0064] This embodiment provides an automobile engine turbocharger elbow joint. The engine turbocharger elbow joint is made of high-strength structural steel as a whole, including an upper port 1 and a lower port 2, and a belt is passed between the upper port 1 and the lower port 2. The curved connecting pipe 3 is connected with each other. The curved connecting pipe 3 is trumpet-shaped, that is, it gradually becomes wider from the upper port 1 to the lower port 2. The upper port 1 expands outward along its circumference with a polygonal connection block 4, and the polygonal connection The block 4 is a hollow structure, that is, it has a hollow inner cavity 5 filled with a leak-proof airtight seal 6, the leak-proof airtight seal 6 is made of EPDM rubber, and the connecting block 4 is evenly distributed with bolt connection holes 7 , the outer surface of the connecting pipe 3 is provided with a gas connection hole 8 near the upper port 1, the side wall of the connecting pipe 3 ne...

Embodiment 2

[0093] This embodiment provides an automobile engine turbocharger elbow joint. The engine turbocharger elbow joint is made of high-strength structural steel as a whole, including an upper port 1 and a lower port 2, and a belt is passed between the upper port 1 and the lower port 2. The curved connecting pipe 3 is connected with each other. The curved connecting pipe 3 is trumpet-shaped, that is, it gradually becomes wider from the upper port 1 to the lower port 2. The upper port 1 expands outward along its circumference with a polygonal connection block 4, and the polygonal connection The block 4 is a hollow structure, that is, it has a hollow inner cavity 5 filled with a leak-proof airtight seal 6, the leak-proof airtight seal 6 is made of EPDM rubber, and the connecting block 4 is evenly distributed with bolt connection holes 7 , the outer surface of the connecting pipe 3 is provided with a gas connection hole 8 near the upper port 1, the side wall of the connecting pipe 3 ne...

Embodiment 3

[0122] This embodiment provides an automobile engine turbocharger elbow joint. The engine turbocharger elbow joint is made of high-strength structural steel as a whole, including an upper port 1 and a lower port 2, and a belt is passed between the upper port 1 and the lower port 2. The curved connecting pipe 3 is connected with each other. The curved connecting pipe 3 is trumpet-shaped, that is, it gradually becomes wider from the upper port 1 to the lower port 2. The upper port 1 expands outward along its circumference with a polygonal connection block 4, and the polygonal connection The block 4 is a hollow structure, that is, it has a hollow inner cavity 5 filled with a leak-proof airtight seal 6, the leak-proof airtight seal 6 is made of EPDM rubber, and the connecting block 4 is evenly distributed with bolt connection holes 7 , the outer surface of the connecting pipe 3 is provided with a gas connection hole 8 near the upper port 1, the side wall of the connecting pipe 3 ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com