Tensile vibration isolation device

A vibration isolation and tensile technology, applied in the field of vibration isolation devices and vibration isolation devices, can solve the problems of seesaw effect, endanger the safety of ship power equipment, failure of vibration isolation system, etc., and achieve broad market application prospects, vibration isolation Stable and reliable performance, high vibration isolation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

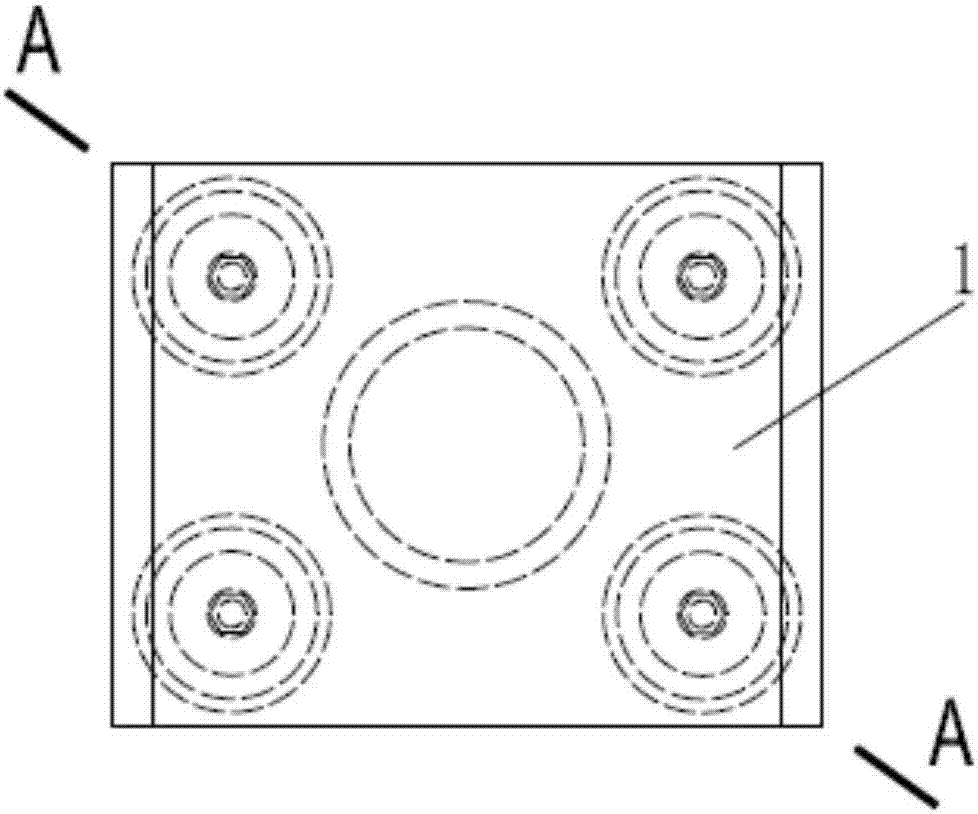

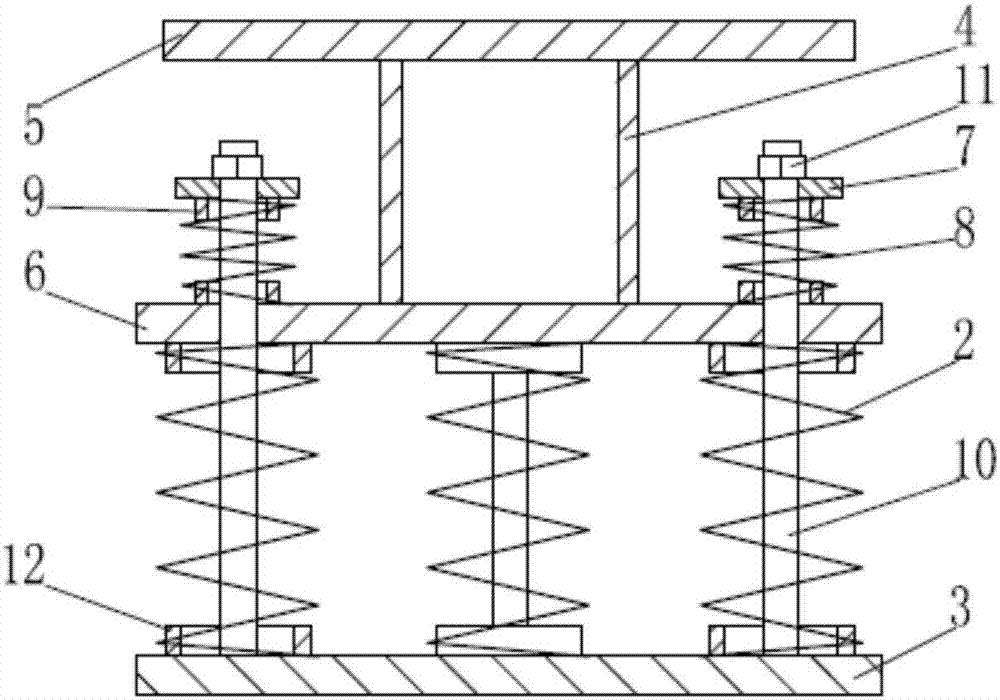

[0026] Such as figure 1 , figure 2 The tensile and vibration isolation device of the present invention shown includes a base plate 3 and an elastic support element 2. The elastic support element is a metal compression spring composed of spiral steel springs. There are four spiral steel springs. In addition, it also includes a back pressure The elastic element 8, the back pressure plate 7 and the connecting piece 1. The back pressure elastic element 8 is specifically a spiral steel spring. The back pressure elastic element 8 and the elastic supporting element 2 are arranged in one-to-one correspondence. The connecting piece 1 consists of a connecting tube 4, The middle bearing plate 6 and the outer connecting plate 5 are welded and combined, the base plate 3 is provided with a connecting rod 10, and the bottom end of the connecting rod 10 is welded and fixedly connected to the base plate 3, and the counter pressure plate 7 and its limiting member 11 are arranged on the connecting...

Embodiment 2

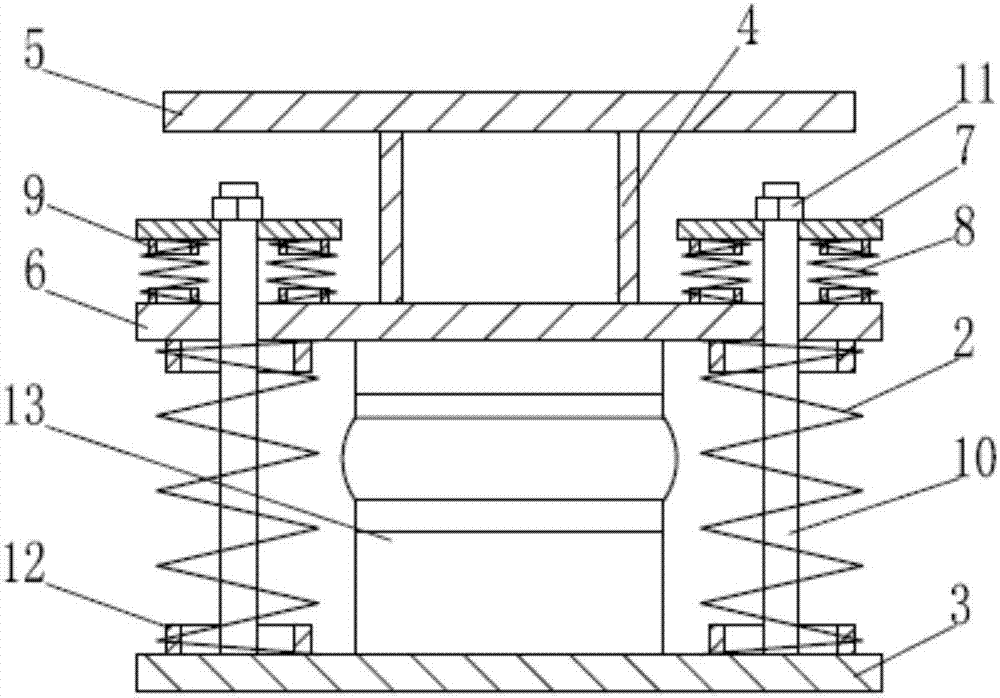

[0031] Such as image 3 The difference between the tensile and vibration isolation device of the present invention shown in the first embodiment is that each group of counter-pressure elastic elements 8 matched with the counter-pressure plate 7 includes two compression springs, and the compression springs are specifically coil steel springs. In addition, the connecting rod 10 passes through the gap surrounded by the plurality of compression springs and is connected to the counter pressure plate 7, and the two compression springs are arranged symmetrically and evenly around the connecting rod 10. In addition, in order to improve the vibration damping and energy consumption capacity of the tensile vibration isolation device of the present invention, a damping device is also provided between the middle bearing plate 6 and the base plate 3, and the damping device is specifically a viscous damping device 13.

[0032] Compared with the first embodiment, in the technical solution describ...

Embodiment 3

[0035] Such as Figure 4 with Figure 5 The difference between the tensile and vibration isolation device of the present invention shown in the first embodiment is that the counter-pressure plate 7 is an integral rectangular plate, and a central through hole is provided in the middle of the plate body to make way for the connecting pipe 4. In addition, a damping device is provided between the counter pressure plate 7 and the middle bearing plate 6, and the damping device is specifically four hydraulic damping devices 14.

[0036] Compared with the second embodiment, in the technical solution described in this example, the damping device is arranged between the counter pressure plate 7 and the middle bearing plate 6, which can leave more space for placing the elastic support element 2 to fully satisfy the heavy load. Under the conditions, the use of a larger number of elastic support elements is required; in addition, due to the damping device provided between the back pressure pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com