Oil-saving type swirling flow burner port ignition device of W-type boiler

An ignition device and a technology of flowing fire, which are applied in the direction of ignition by guiding the flame, combustion ignition, combustion type, etc., can solve the problems of weak ignition effect of oil flame, long distance, large fuel consumption of W-type boiler ignition, etc., and achieve fog The effect of improving the burnout degree of pulverized coal is excellent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0015] figure 1 It is a structural schematic diagram of an existing oil gun ignition device for a W-type boiler, and its structure has been described above, and will not be repeated here.

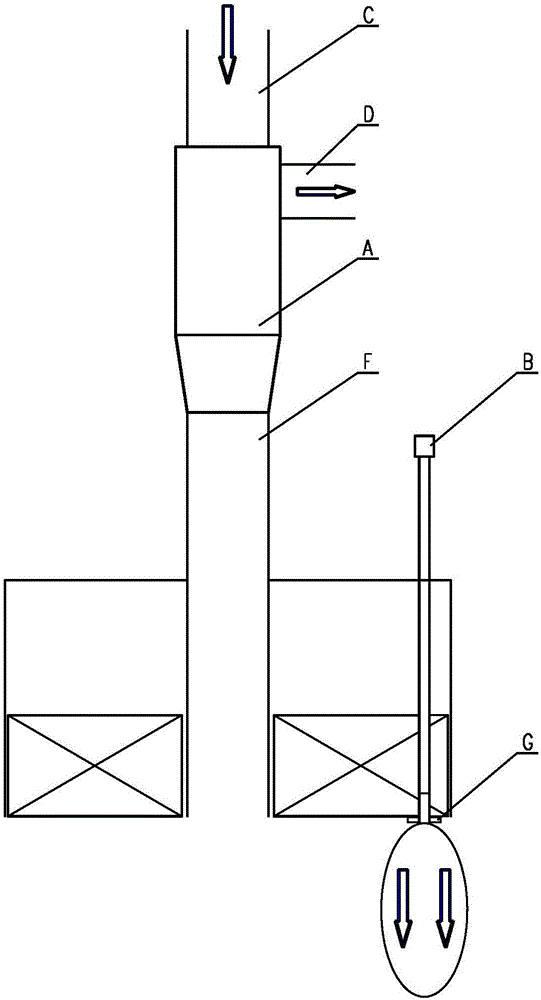

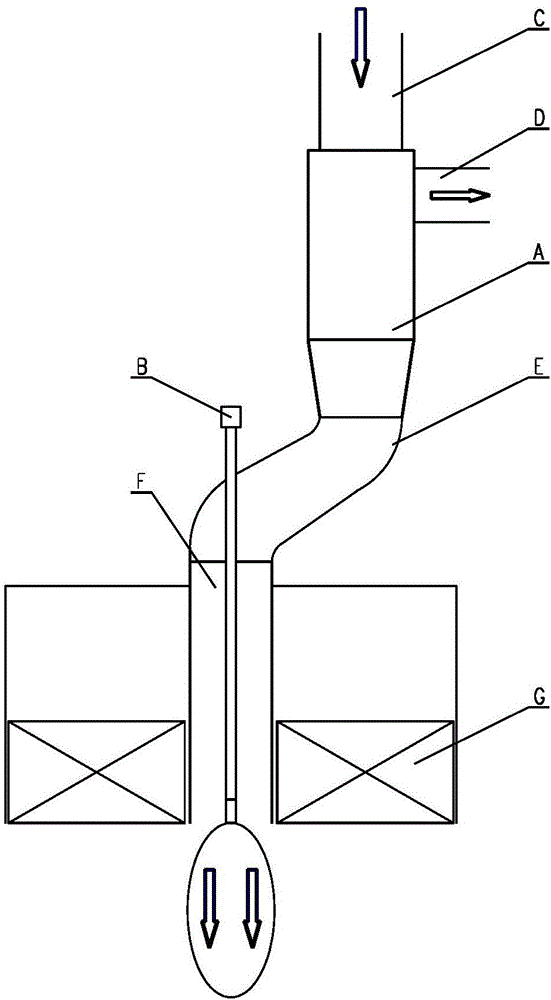

[0016] Figure 2~3 The oil-saving swirling burner ignition device for a W-type boiler shown in , includes a pulverized coal concentration separator A and an ignition spray gun B. One end of the pulverized coal concentration separator A is provided with a primary air inlet C, and its side wall is provided with an exhaust gas outlet. D. The other end of the pulverized coal concentration separator A is connected to the swirling nozzle F through an elbow connecting pipe E. The bending part of the elbow connecting pipe E is interspersed with an ignition spray gun B, and the ignition spray gun B is the same as the central tube of the swirling nozzle F. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com