Sputtering thin film temperature-pressure composite sensor and manufacturing method thereof

A composite sensor, temperature and pressure technology, applied in thermometers, measuring fluid pressure, fluid pressure measurement by changing ohmic resistance, etc., can solve problems such as high cost, large temperature difference, consistency, and yield impact, and achieve high The effect of stability, high reliability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with the accompanying drawings, the low cost, low power consumption, high reliability, high stability, and long life solution provided by the present invention can be used to simultaneously measure gas, liquid medium temperature, and pressure data at a single measuring point or without changing the original system. On the basis of the pipeline structure, the optimization method of the technical solution adopted for the measurement and monitoring problems such as adding temperature measurement function to the original pressure measurement point is further explained:

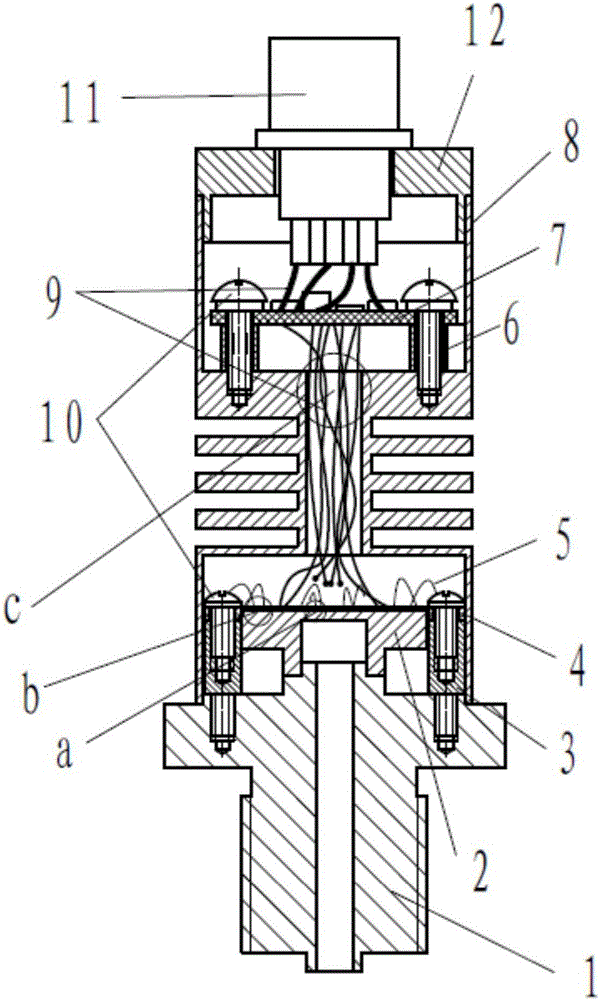

[0019] Such asfigure 1 As shown, the sputtered film temperature and pressure composite sensor of the present invention includes a nozzle 1, a sensitive element 2, a copper column 3, a compensation plate 4, a gold lead 5, a sleeve 6, a signal processing circuit board 7, a housing 8, and a wire 9 , fastening screw 10, aviation socket 11 and socket base 12. The sensitive element 2 is forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com