Improved mortar test device

A test device and an improved technology, applied in the direction of measuring devices, fuel testing, material inspection products, etc., can solve the problems of affecting test results, difficult to guarantee safety, inconvenient testing, etc., to achieve fast and accurate testing, saving space and volume zoom out effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

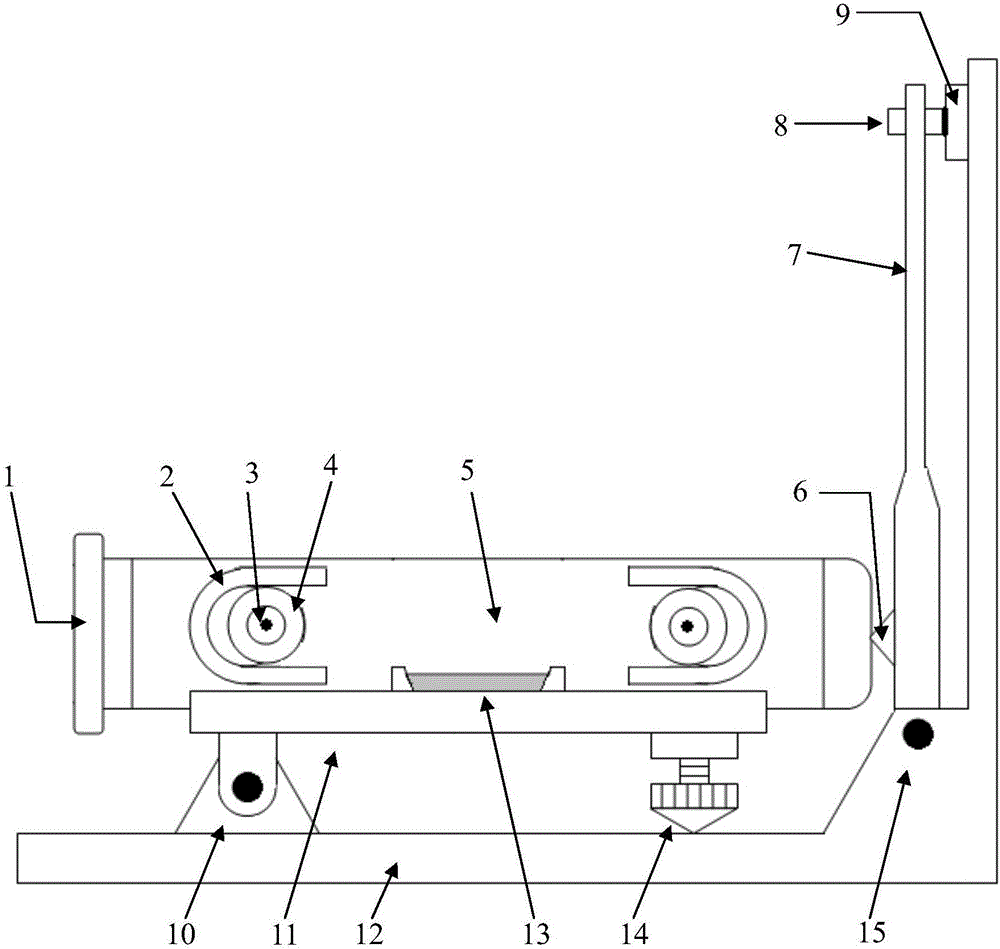

[0029] An improved mortar test device, its structure is as follows figure 1 Shown, comprise mortar 5, gun carriage 11, base 12 and pressure sensor 9. The muzzle 1 is arranged at the front end of the gun mount 5 , and the bottom of the gun mount 5 is connected to the base 12 through the hinge 10 and the conical horizontal adjusting bolt 14 respectively. The mortar 5 is placed horizontally on the gun frame 11, and has two pairs of gun lugs 3 at the front and rear. The gun ears 3 are placed in two pairs of short slide rails 2 symmetrically arranged on the gun frame 5 through bearings 4. The short slide rails 2 The upper and lower end surfaces are horizontal, so that the mortar 5 can only move laterally along the short slide rail 2 after detonating. A level ruler 13 is also installed on the upper surface of the gun mount 11, which can cooperate with the level adjusting bolt 14 to adjust the level of the gun mount 11.

[0030] Vertically by installing unequal arm lever 7 at the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com