Microstrip isolator

An isolator and microstrip technology, applied in the directions of waveguide devices, electrical components, circuits, etc., can solve the problems of the gap between the bottom plate and the external circuit, the influence of the planeness of the bottom plate, and the use of the isolator.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

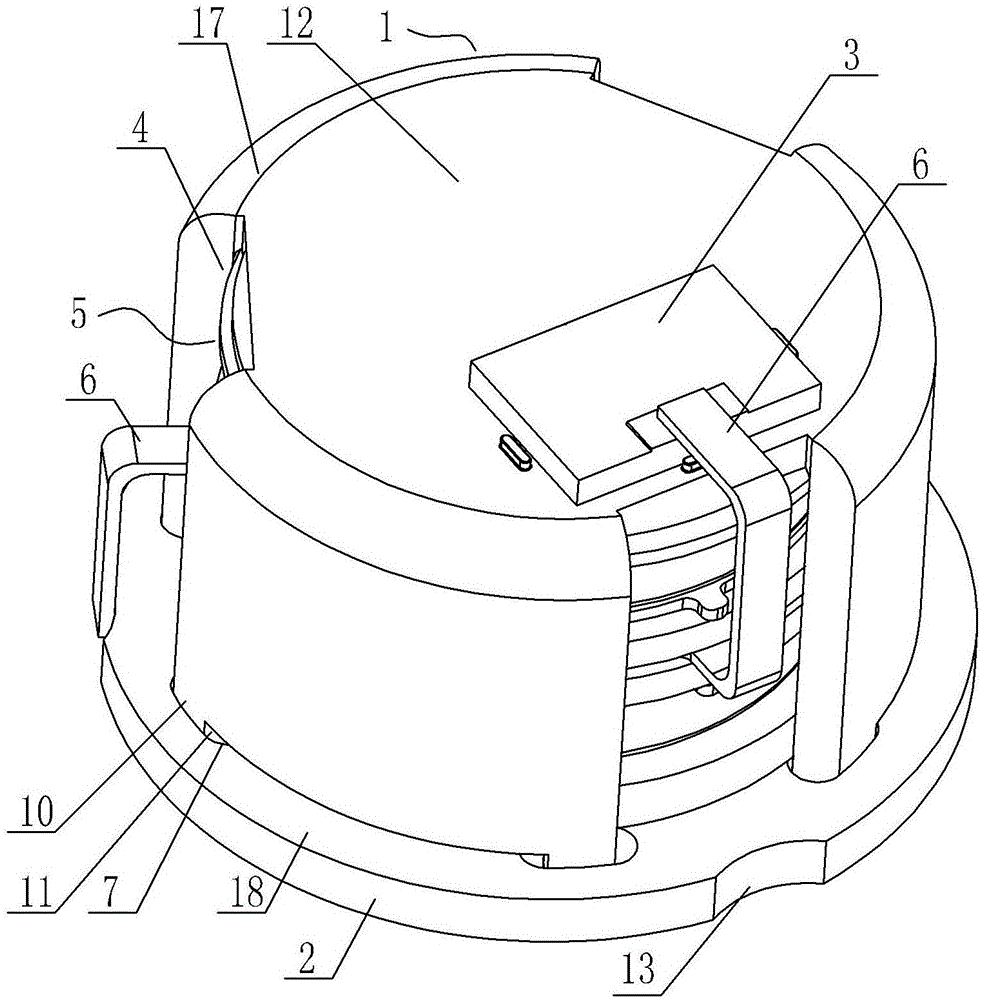

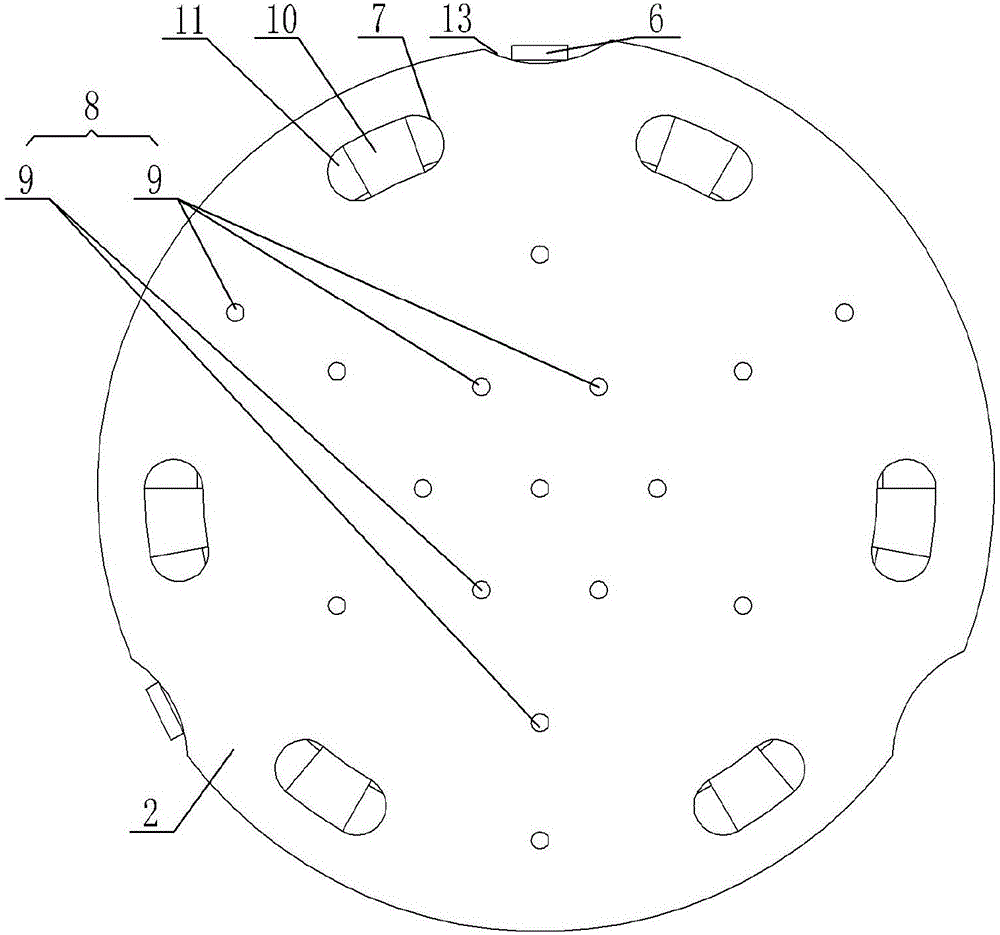

[0037] The monomer isolator of specific embodiment one, see figure 1 , figure 2: The resistor 3 is located on the upper end surface of the cover plate 12 of the covered cylinder 1, and the pin 6 corresponding to the connection resistor 3 passes through the corresponding avoidance groove 4 and then is bent upwards and then connected to the resistor 3. The upper end surface of the cover plate 12 corresponds to The position of the resistor 3 is coated with solder paste, and the resistor 3 is fixedly connected to the solder paste at the corresponding position by reflow soldering (this structure is an existing mature structure, not shown in the figure), and the pin 6 of the non-connected resistor 3 runs through the corresponding The avoidance groove 4 is bent downwards, and its lower end is located at the pin avoidance groove 13 corresponding to the base plate 2. The surface of the pin avoidance groove 13 is provided with copper foil, and the lower ends of the pins 6 of the two no...

Embodiment 1

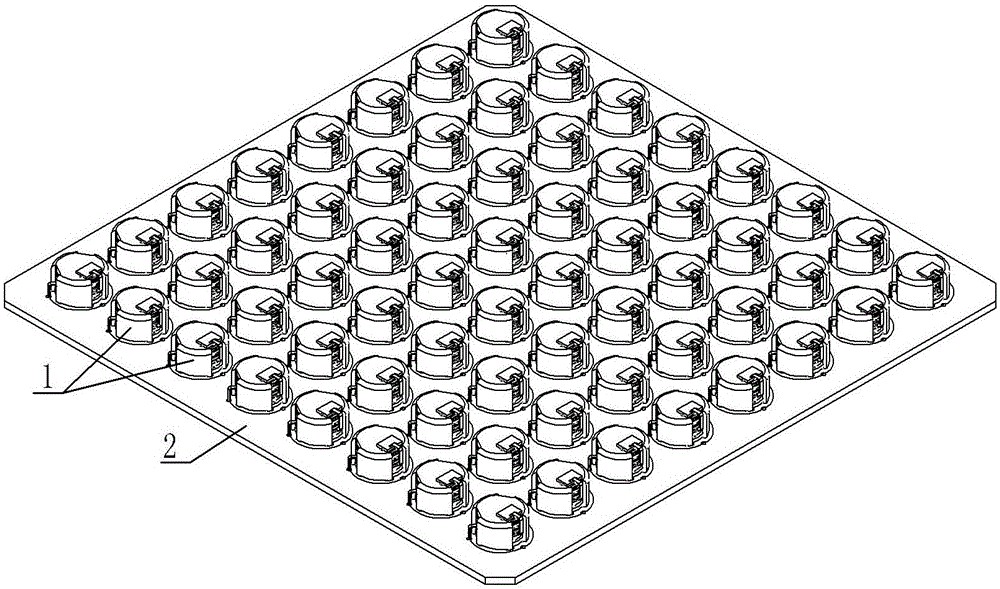

[0038] The matrix isolator of embodiment one, see image 3 : The shape of the bottom plate 1 is a rectangle, and a plurality of metal connection parts 7 corresponding to a single isolator, a central metal connection area 8, a positioning hole groove 11, and a pin avoidance groove 13 are combined to form a processing unit. A plurality of processing units are arranged, and a single covered cylinder 1 with an internal element 5 is positioned one by one in the corresponding positioning hole groove 11 on the corresponding processing unit, and the lower end of the pin 6 is located in the pin avoidance groove at the corresponding position In 13, the rectangular bottom plate 1 is specifically a PCB board, and matrix-type isolators are arranged on the rectangular PCB board to meet various needs and realize the use of multiple frequency bands, so that the isolators in the entire device can be arranged in a centralized manner, saving A lot of space for equipment.

specific Embodiment 2

[0039] The monomer isolator of specific embodiment two, see Figure 4 : Resistor 3 is set on the bottom plate 1, the pin 6 corresponding to the connection resistor 3 penetrates the corresponding avoidance groove 4 and then bends down to connect to the resistor 3, and the pin 6 of the non-connected resistor 3 penetrates the corresponding avoidance groove 4 and then goes downward Bend, the lower end of which is located in the pin avoidance groove 13 corresponding to the base plate 2, the groove surface of the pin avoidance groove 13 is provided with copper foil, and the lower ends of the pins 6 of the two non-connected resistors 3 are lapped on the copper foil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com