Elastic breathable fold-type composite non-woven fabric and forming method

A molding method and non-woven fabric technology, which is applied in the field of medical elastic bandages and diaper waistline manufacturing, can solve the problems of poor elasticity, limited elasticity, and low viscosity, and achieve the advantages of reduced composite area, air permeability, and increased stretch rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

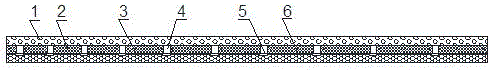

[0010] Embodiment 1: with reference to attached figure 1 . An elastic breathable crepe composite non-woven fabric, including non-woven fabric, the film surface of the elastic film 2 has many air holes 4, and the elastic film 2 with many air holes 4 is in a stretched state and the surface non-woven fabric 1 and the bottom non-woven fabric 3 are hot-compressed and composited to form an elastic and breathable crepe composite non-woven fabric, and the elastic film 2 is located between the surface non-woven fabric 1 and the bottom non-woven fabric 3 .

[0011] The elastic film is an elastic perforated air-permeable film, or an elastic air-permeable film. The air holes in the elastic perforated air-permeable film 2 are formed by suction through the negative pressure suction flow channel on the roller surface full of negative pressure holes, and the air-perforated orifice is formed along the convex platform mouth 5; or the elastic perforated air-permeable film 2 The air hole in the...

Embodiment 2

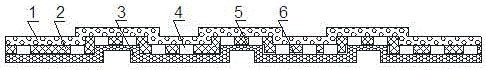

[0013] Embodiment 2: with reference to attached figure 2 . On the basis of Example 1, the surface layer non-woven fabric 1 and the bottom layer non-woven fabric 3 are hot-compressed and composited on both sides of the elastic breathable film 2 by a convex-concave roller group in the state where the elastic air-permeable film 2 is stretched to form a Concave-convex surface wrinkled elastic breathable composite non-woven fabric and the composite bonding surface is a concave-convex surface, that is, the bonding composite part of the surface layer non-woven fabric 1 and the bottom non-woven fabric 3 and the elastic film 2 is a concave-convex pressing surface, not a concave-convex pressing surface. The surfaces are not bonded.

Embodiment 3

[0014] Embodiment 3: On the basis of Embodiment 1, the bottom non-woven fabric 3 is compounded with the boss mouth 5 in the perforated air-permeable film 2, and the bottom non-woven fabric surface and the elastic perforated film are formed. The hollow multi-point support space 6 with multiple paths and interlinked paths, that is, the bottom non-woven fabric 3 is composited with the orifice convex platform formed by negative pressure suction in the perforated air-permeable film 2, and the non-composite part forms a breathable interlinked space. space.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com