Elastic breathable crepe composite non-woven fabric and its forming method

A non-woven fabric and crepe technology, which is applied in the field of elastic breathable crepe composite non-woven fabric and forming, can solve the problems of poor quality, limited elasticity, low viscosity, etc., and achieve reduction of composite area, air permeability, stretchability good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

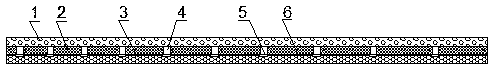

[0010] Embodiment 1: with reference to attached figure 1 . An elastic breathable crepe composite non-woven fabric, including non-woven fabric, the film surface of the elastic film 2 has many air holes 4, and the elastic film 2 with many air holes 4 is in a stretched state and the surface non-woven fabric 1 and the bottom non-woven fabric 3 are hot-compressed and composited to form an elastic and breathable crepe composite non-woven fabric, and the elastic film 2 is located between the surface non-woven fabric 1 and the bottom non-woven fabric 3 .

[0011] The elastic film is an elastic perforated air-permeable film, or an elastic air-permeable film. The air holes in the elastic perforated air-permeable film 2 are formed by suction through the negative pressure suction flow channel on the roller surface full of negative pressure holes, and the air-perforated orifice is formed along the convex platform mouth 5; or the elastic perforated air-permeable film 2 The air hole in the...

Embodiment 2

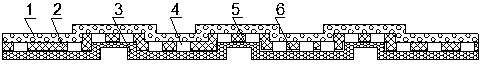

[0013] Embodiment 2: with reference to attached figure 2 . On the basis of Example 1, the surface layer non-woven fabric 1 and the bottom layer non-woven fabric 3 are hot-compressed and composited on both sides of the elastic breathable film 2 by a convex-concave roller group in the state where the elastic air-permeable film 2 is stretched to form a Concave-convex surface wrinkled elastic breathable composite non-woven fabric and the composite bonding surface is a concave-convex surface, that is, the bonding composite part of the surface layer non-woven fabric 1 and the bottom non-woven fabric 3 and the elastic film 2 is a concave-convex pressing surface, not a concave-convex pressing surface. The surfaces are not bonded.

Embodiment 3

[0014] Embodiment 3: On the basis of Embodiment 1, the bottom non-woven fabric 3 is compounded with the boss mouth 5 in the perforated air-permeable film 2, and the bottom non-woven fabric surface and the elastic perforated film are formed. The hollow multi-point support space 6 with multiple paths and interlinked paths, that is, the bottom non-woven fabric 3 is composited with the orifice convex platform formed by negative pressure suction in the perforated air-permeable film 2, and the non-composite part forms a breathable interlinked space. space.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com