Polyether sulfone porous film preparation method

A polyethersulfone and porous membrane technology, which is applied in the field of preparation of polyethersulfone porous membrane materials, can solve the problem of insufficient mechanical properties and stability of the honeycomb ordered membrane, limiting the practical application of the honeycomb ordered membrane, and the pore size distribution inside the membrane. Irregularity and other problems, to achieve the effect of cheap raw materials, good connectivity, and large porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

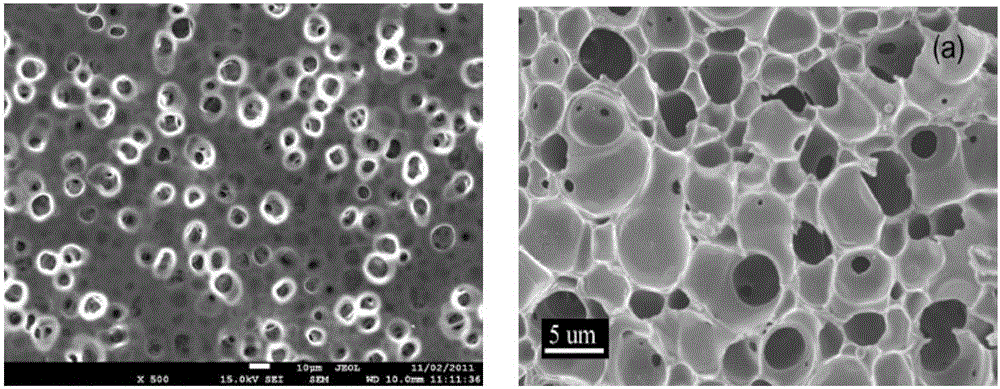

[0022] Add 1 g of glucose into an organic solvent composed of 60 mL of N-methylpyrrolidone and 20 mL of acetone, and stir until dissolved. Then add 9 g of polyethersulfone, stir and dissolve at 60 °C, degas at a constant temperature, and then scrape the film on the surface of a clean and dry glass plate with a scraper. The thickness of the casting solution is 200 μm, and then put the glass plate coated with the casting solution on the Into a room with a humidity of 75%, the film will form after 2 hours. figure 1 For the surface and cross-sectional morphology of the prepared membrane, it can be seen from the figure that the pores of the membrane have good connectivity.

Embodiment 2

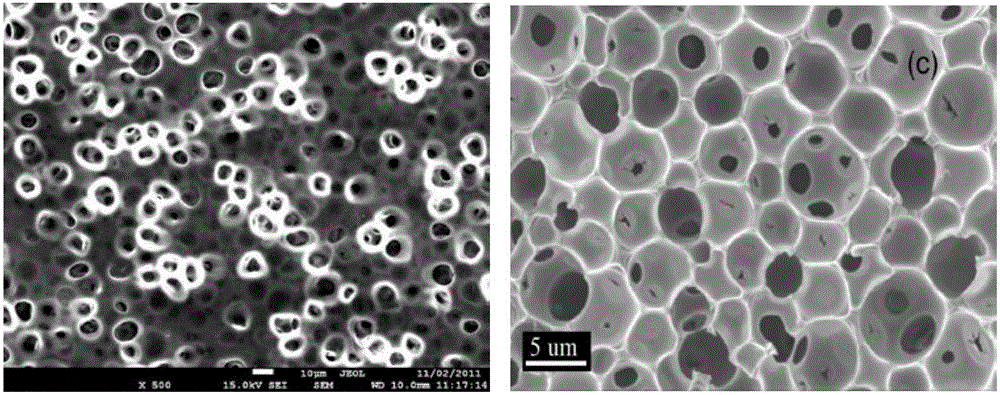

[0024] Add 2 g of glucose into an organic solvent composed of 60 mL of N-methylpyrrolidone and 20 mL of acetone, and stir until dissolved. Then add 8 g of polyethersulfone, stir and dissolve at 60°C, degas at a constant temperature, and then use a scraper to scrape the film on the surface of a clean and dry glass plate. The thickness of the casting solution is 200 μm, and then put the glass plate coated with the casting solution on the Into a room with a humidity of 75%, the film formed after 2 hours. figure 2 For the surface and cross-sectional morphology of the prepared membrane, it can be seen from the figure that the membrane pores are a three-dimensional network structure with good connectivity, and the diameter of the membrane pores is about 5 μm.

Embodiment 3

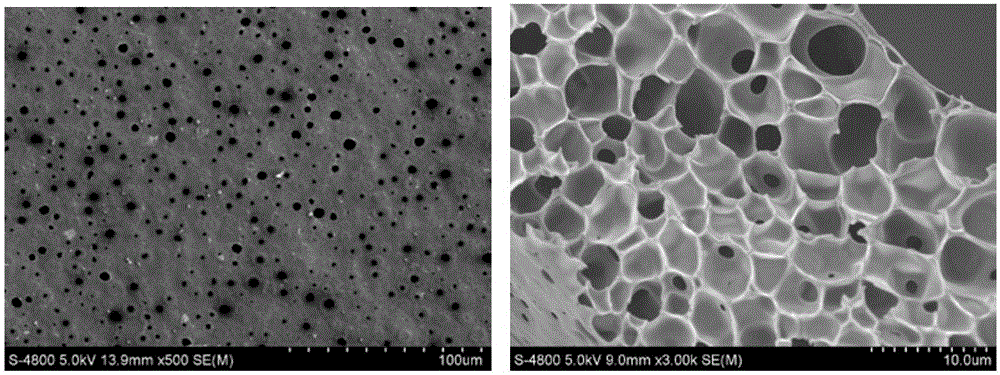

[0026] Add 3 g of glucose into an organic solvent composed of 60 mL of N-methylpyrrolidone and 20 mL of acetone, and stir until dissolved. Then add 7 g of polyethersulfone, stir and dissolve at 60°C, degas at a constant temperature, and then use a scraper to scrape the film on the surface of a clean and dry glass plate. The thickness of the casting solution is 200 μm, and then put the glass plate coated with the casting solution on the Into a room with a humidity of 75%, the film formed after 2 hours. image 3 For the surface and cross-sectional morphology of the prepared membrane, it can be seen from the figure that the membrane pore diameter is about 6 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com