Buckling-restrained steel plate shear wall structure easy to assemble

A steel plate shear wall and anti-buckling technology, which is applied to walls, shockproof, household walls, etc., can solve the problems of short time and ineffective restraint of wall panels, etc., to improve mechanical performance, smooth hysteresis curve, and improve long-term performance and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings:

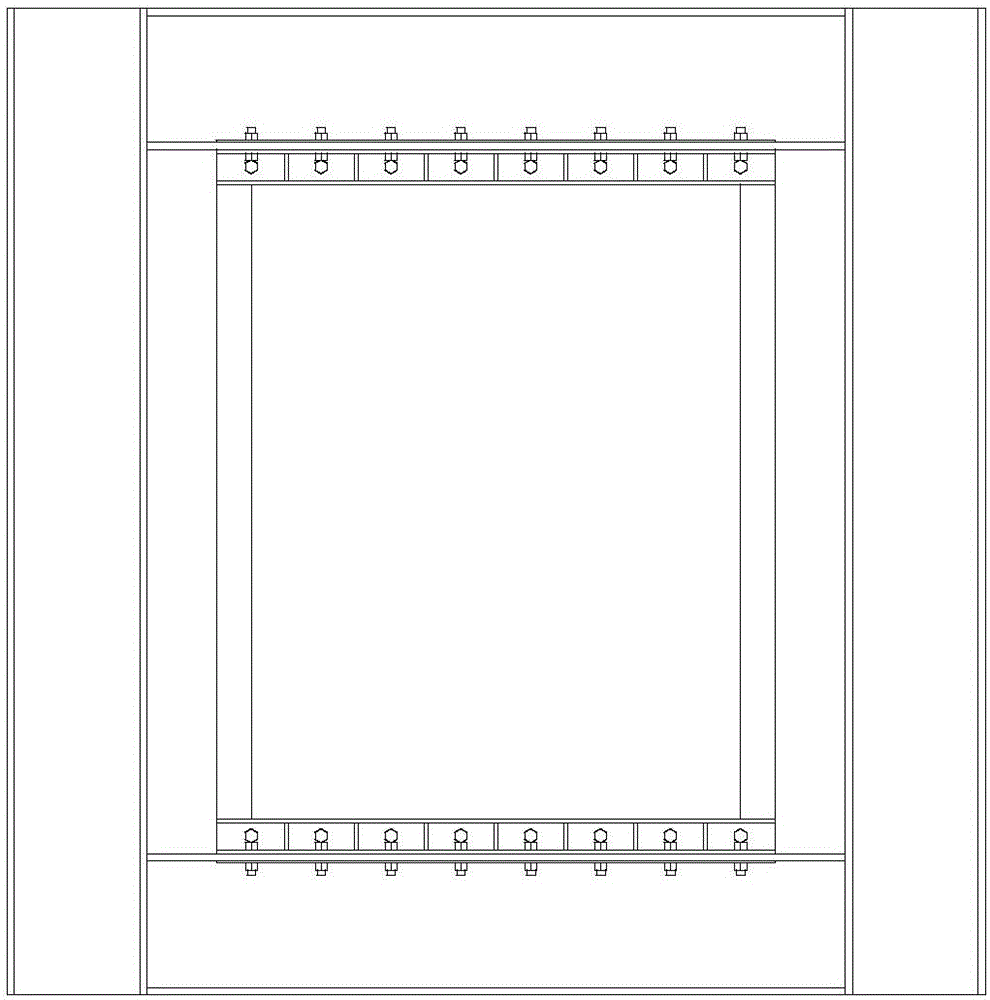

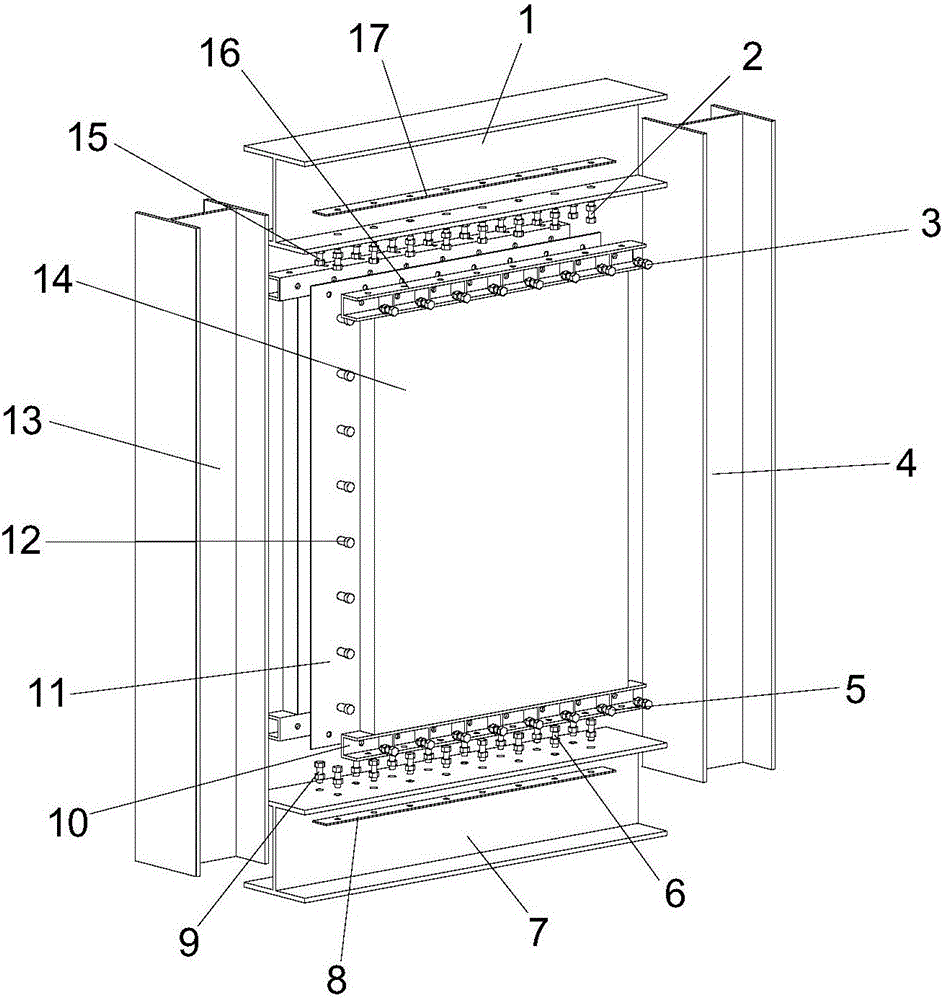

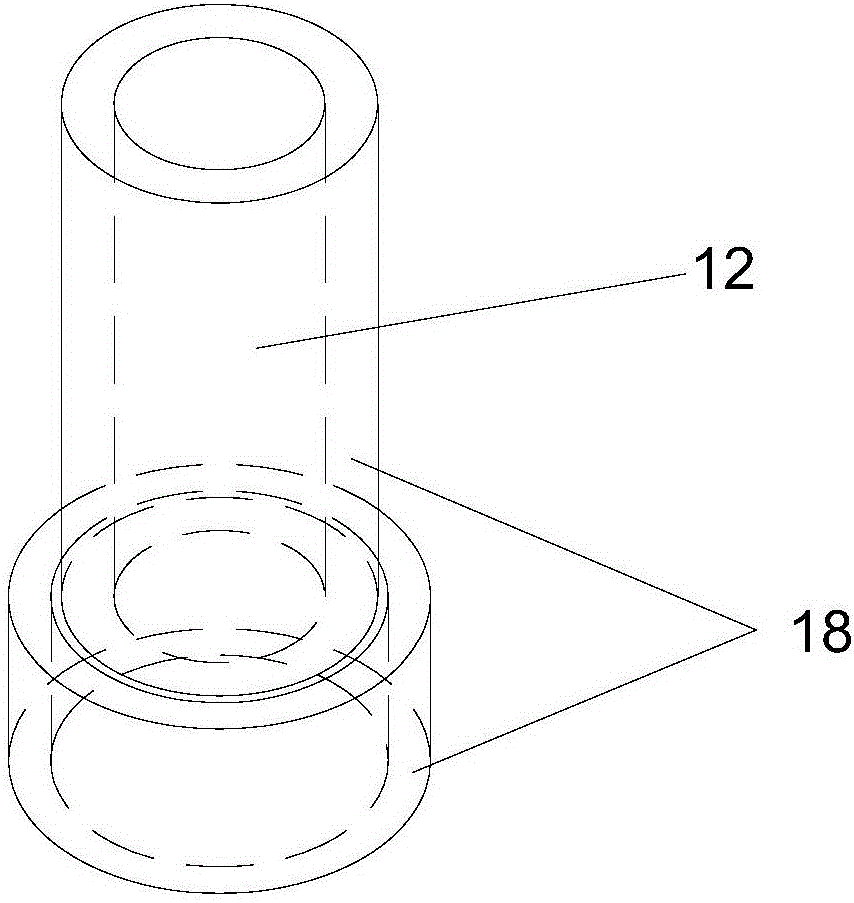

[0026] reference figure 1 and figure 2 The easy-to-assemble buckling steel plate shear wall structure of the present invention includes a first horizontal edge member 1, a second horizontal edge member 7, a first vertical edge member 13, a second vertical edge member 4, a steel plate 11, a first Channel steel connector 16, second channel steel connector, third channel steel connector 10, fourth channel steel connector, several first screw-type studs 12 and several second screw-type studs; first horizontal edge member The two ends of 1 are respectively connected to the upper end of the first vertical edge member 13 and the upper end of the second vertical edge member 4, and the two ends of the second horizontal edge member 7 are respectively connected to the lower end and the second vertical edge of the first vertical edge member 13 The lower end of the member 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com