Deep sea mining method and deep sea mining apparatus

A deep-sea mining and concentrate technology, which is applied in mining minerals, special mining, chemical instruments and methods, etc., can solve problems such as tailings processing troubles, inaccurate ore dressing, waste of transport capacity, etc., to reduce processing costs, reduce transportation costs, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the drawings and specific embodiments.

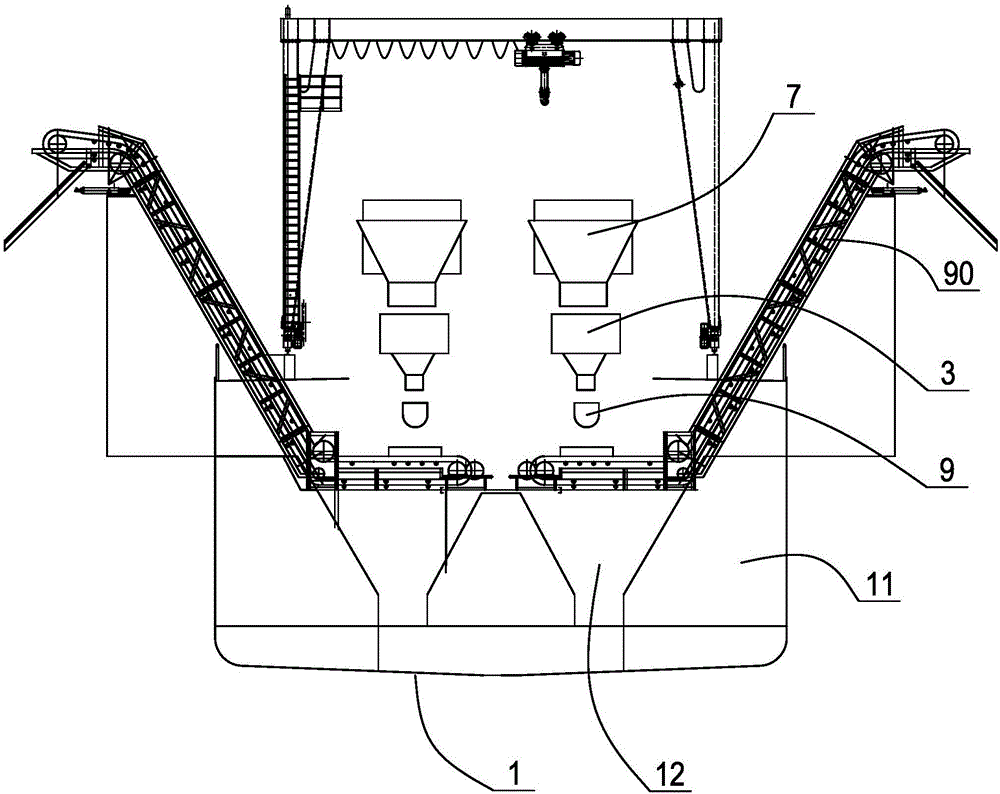

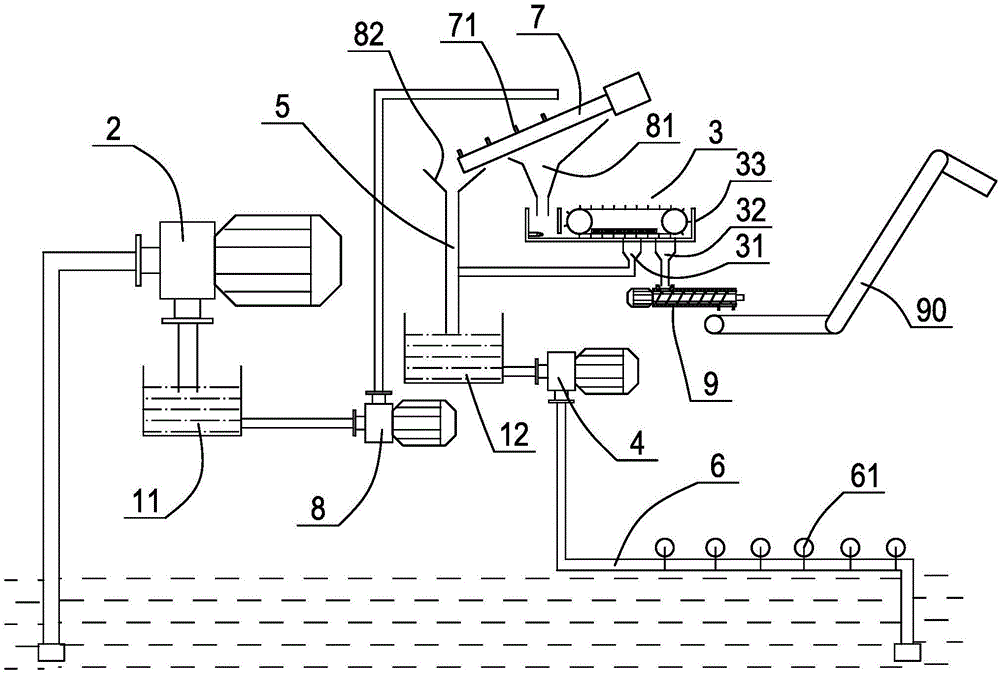

[0038] Such as figure 1 , figure 2 As shown, a deep-sea mining floating platform is mainly used for the collection and beneficiation of seabed raw ore. The deep-sea mining floating platform includes a hull 1 floating on the sea surface, and a raw ore warehouse 11 and tailings are separately arranged in the lower part of the hull. Warehouse 12, similar to the existing mining ship, the raw ore on the seafloor is pumped by a high-power sand pumping pump 2, which is powered by a diesel engine, and the sand suction port of the sand pumping pump is connected to the seabed through a pipeline. The sand outlet of the sand pump is connected to the original ore bin through a pipeline, so that the raw ore can be pumped into the original ore bin.

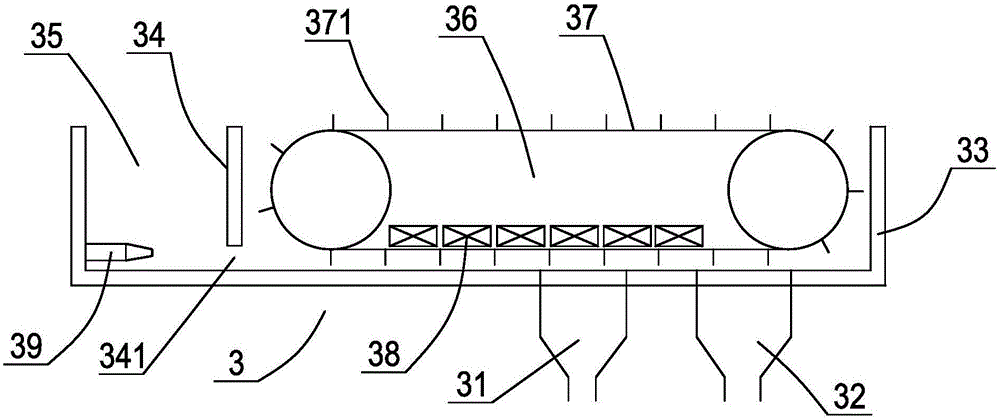

[0039] Different from the prior art, the present invention directly installs a magnetic separator 3 for beneficiation on the hu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com