Alternating current driven quantum dot light emitting diode, and preparation method and application thereof

A quantum dot light-emitting, AC-driven technology, applied in the direction of circuits, electrical components, electrical solid devices, etc., can solve the problems of unfavorable industrialization promotion, multiple dielectric layers, complex structures, etc., and achieve large-scale industrialization Promotion and application, the effect of mature and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] Correspondingly, the embodiment of the present invention also provides a method for manufacturing an AC-driven quantum dot light-emitting diode, comprising the following steps:

[0045] S01. Depositing a bottom electrode on the substrate, and depositing a quantum dot luminescent layer on the bottom electrode;

[0046] S02. Depositing a first ionic liquid layer on the quantum dot light-emitting layer;

[0047] S03. Depositing a top electrode on the first ionic liquid layer.

[0048] Specifically, the deposition of the bottom electrode, quantum dot light-emitting layer, and top electrode can be achieved by conventional methods in the art. The first ionic liquid layer is preferably prepared by a solution processing method.

[0049] Preferably, before depositing the quantum dot light-emitting layer, it also includes depositing a second ionic liquid layer and / or an insulating layer on the bottom electrode. The diionic liquid layer is preferably prepared by a solution proc...

Embodiment 1

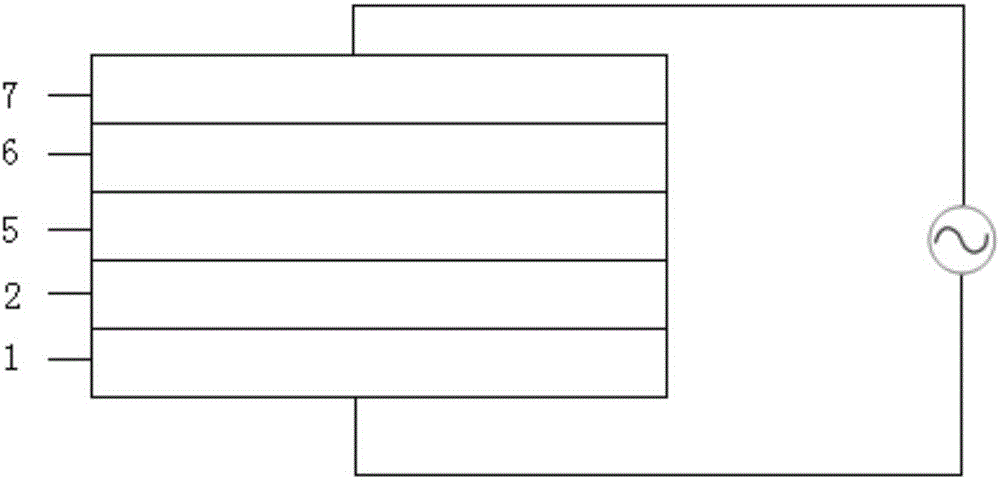

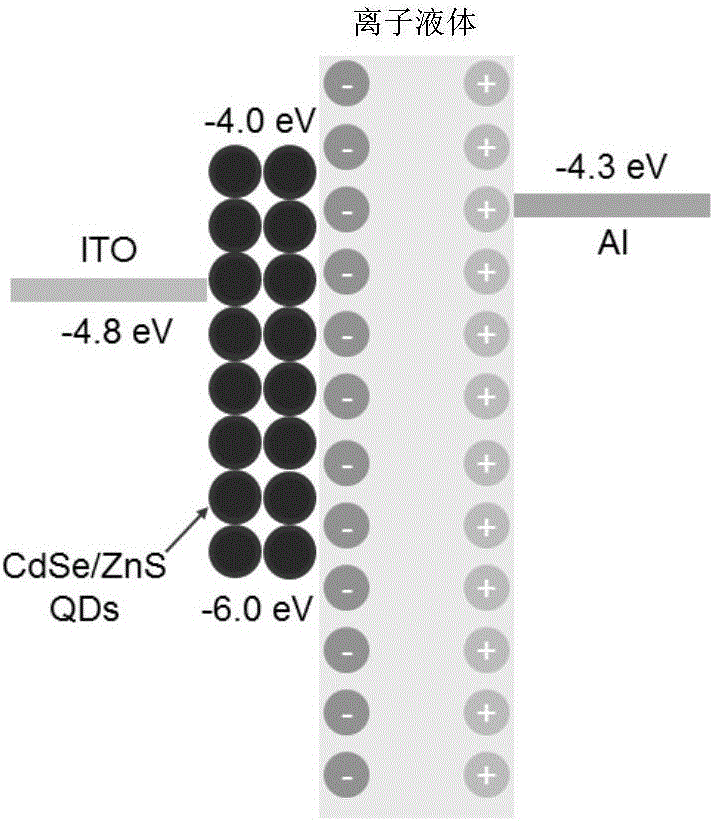

[0058] An AC-driven quantum dot light-emitting diode, such as figure 1 As shown, it includes a substrate 1, a bottom electrode 2, a quantum dot light-emitting layer 5, a first ionic liquid layer 6, and a top electrode 7 that are sequentially stacked, wherein the substrate 1 is a glass substrate, and the bottom electrode 2 ITO, the quantum dot luminescent layer 5 is a CdSe / ZnS quantum dot luminescent layer, and the first ionic liquid layer 6 is N,N-diethyl-N-methyl-N-(n-propyl) tri Fluoromethyl ammonium trifluoroborate (Et 2 PrNMe-CF 3 BF 3 ) ionic liquid layer with a thickness of 10 nm, and the top electrode 7 is Al.

[0059] The preparation method of the quantum dot light-emitting diode driven by the above alternating current comprises the following steps:

[0060] S11. Spin-coat a layer of CdSe / ZnS quantum dot luminescent layer on the ITO conductive glass;

[0061] S12. Spin-coat a layer of N,N-diethyl-N-methyl-N-(n-propyl) trifluoromethyl ammonium trifluoroborate (Et ...

Embodiment 2

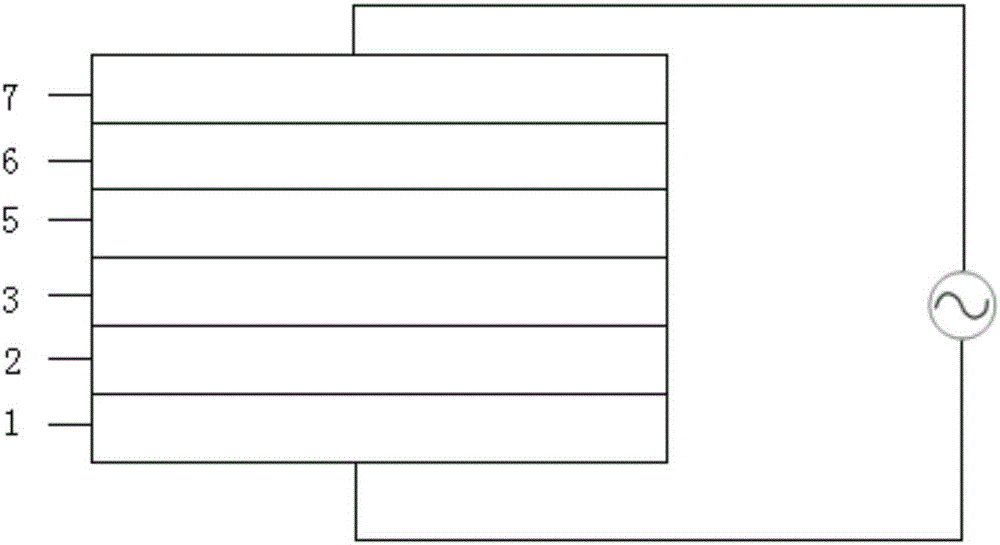

[0065] An AC-driven quantum dot light-emitting diode, such as image 3 As shown, it includes a substrate 1, a bottom electrode 2, a second ionic liquid layer 3, a quantum dot light-emitting layer 5, a first ionic liquid layer 6, and a top electrode 7 that are sequentially stacked, wherein the substrate 1 is a glass substrate Bottom, the bottom electrode 2 is ITO, and the second ionic liquid layer 3 is a 1-butyl-3-methylimidazolium trifluoromethanesulfonate (BMIM-OTF) ionic liquid layer with a thickness of 20nm. The quantum dot luminescent layer 5 is a CdSe / ZnS quantum dot luminescent layer, and the first ionic liquid layer 6 is N,N-diethyl-N-methyl-N-(n-propyl)trifluoromethyltrifluoro Ammonium borate (Et 2 PrNMe-CF 3 BF 3 ) ionic liquid layer with a thickness of 10 nm, and the top electrode 7 is Al.

[0066] The preparation method of the quantum dot light-emitting diode driven by the above alternating current comprises the following steps:

[0067] S21. Spin-coat a layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com