High-strength and high-toughness polypropylene product prepared from nucleating agent self-formed fibers

A polypropylene, high-strength technology, used in the field of high-strength and high-toughness polypropylene parts, can solve the problems of difficulty in simultaneously improving the strength and toughness of polypropylene materials, limited application potential, and increased energy consumption, and achieves significant axial tension. Tensile strength, high quality competitive advantage, enhanced effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

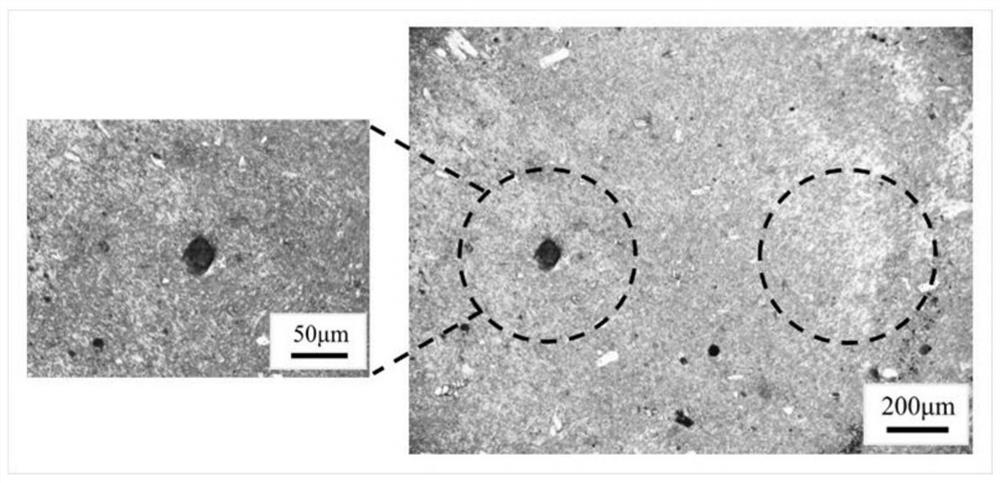

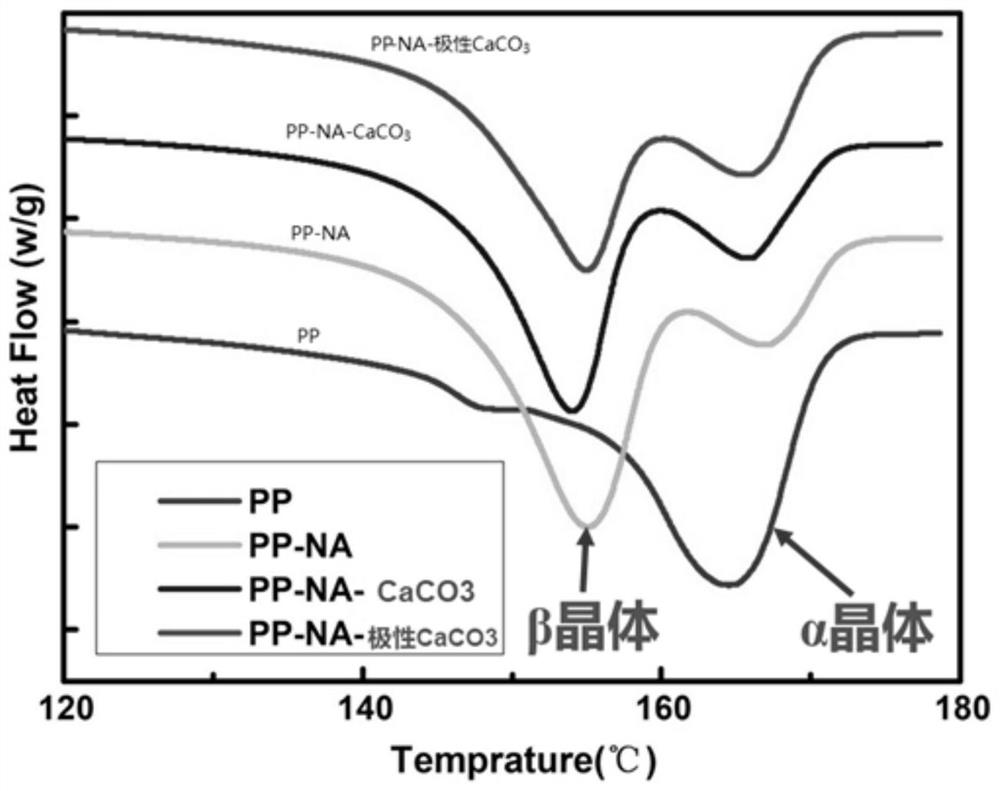

[0037] The ethanolamine-nano-calcium carbonate blend containing 1 wt% of the mass fraction is placed in a ball mill and ball-milled for 10 minutes to prepare ethanolamine-modified nano-calcium carbonate.

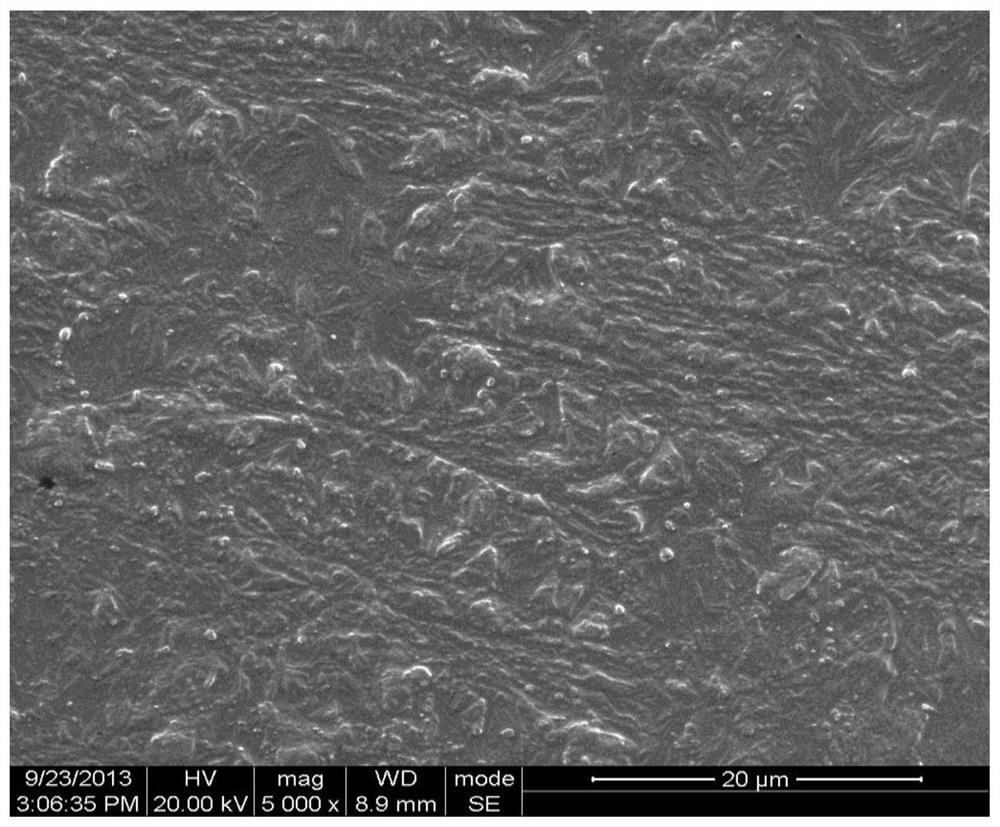

[0038] First put 0.1 part of TMB-5 type β-nucleating agent, 100 parts of homopolypropylene, and 1 part of ethanolamine-modified nano-calcium carbonate into a high-mixer for thorough mixing, then place the mixture in a conventional injection molding device, and extrude The temperature of the melting section of the machine is 200°C, and the temperature of the die is 180°C for melt injection molding, and the standard spline with a length of 100mm, a width of 10mm and a thickness of 4mm is obtained by injection molding.

[0039] The axial tensile strength of the sample is 40.0MPa, the elongation at break is 1000%, and the impact strength is 10.0kJ / m 2 .

Embodiment 2

[0041] Put the blend of triethanolamine and talc powder containing 1wt% mass fraction in a ball mill, and ball mill for 10 minutes to prepare triethanolamine-modified talc powder.

[0042]First put 0.1 part of TMB-5 type β-nucleating agent, 100 parts of homopolypropylene, and 1 part of triethanolamine modified talcum powder into a high-mixer for thorough mixing, then place the mixture in a conventional injection molding device, and extrude The temperature of the melting section of the machine is 210°C, and the temperature of the die section is 200°C for melt injection molding, and the standard spline with a length of 100mm, a width of 10mm, and a thickness of 4mm is obtained by injection molding.

[0043] The axial tensile strength of the sample is 46.2MPa, the elongation at break is 1400%, and the impact strength is 18.7kJ / m 2 .

Embodiment 3

[0045] Put the blend of butanediol and activated carbon containing 1 wt% mass fraction in a ball mill, and ball mill for 10 minutes to prepare butanediol-modified activated carbon.

[0046] First put 0.3 parts of NU-100 type β-nucleating agent, 100 parts of homopolypropylene, and 2 parts of butanediol modified activated carbon into a high-mixer for thorough mixing, then place the mixture in a conventional injection molding device, and extrude The temperature of the melting section of the machine is 200°C, and the temperature of the die section is 190°C for melt injection molding, and a standard sample with a length of 100mm, a width of 10mm, and a thickness of 4mm is obtained by injection molding.

[0047] The axial tensile strength of the spline is 43.6MPa, the elongation at break is 1100%, and the impact strength is 12.9kJ / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com