Device for recycling and utilizing resistance energy in steel wire pay-off process of pipe type stranding machine

An energy recovery and twisting machine technology, applied in circuit devices, battery circuit devices, transportation and packaging, etc., can solve the problems of braking energy loss, inconvenient tension detection and control, poor energy saving, etc., to achieve convenient recovery of lost energy, Improved energy-saving effect and easy-to-control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

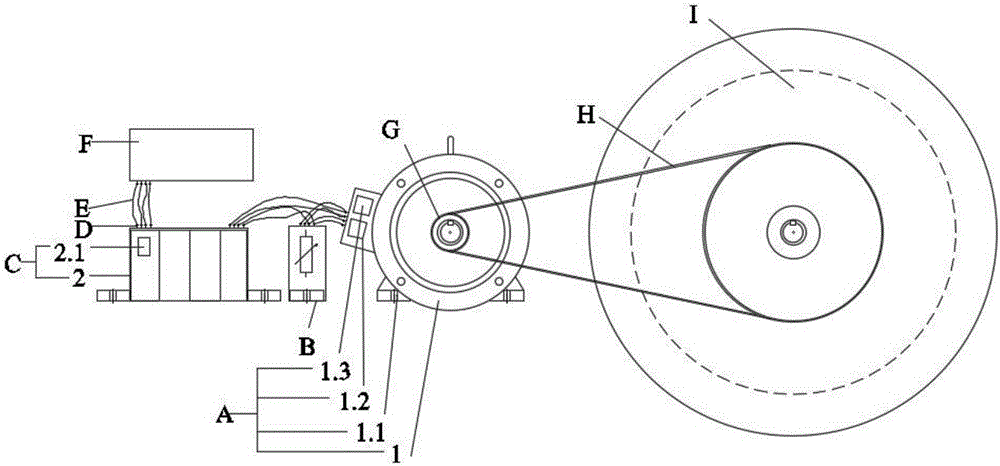

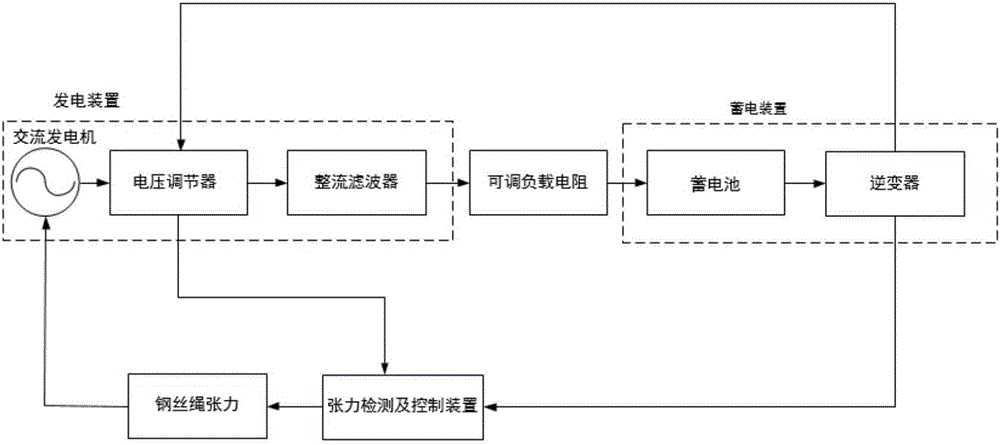

[0023] refer to Figure 1 ~ Figure 4 A device for recovering and utilizing energy lost during braking of a steel wire rope of a tubular stranding machine, including a power generation device A, an electrical storage device C, an adjustable load resistance B, a terminal post D, a wire E, a pulley G and Belt H.

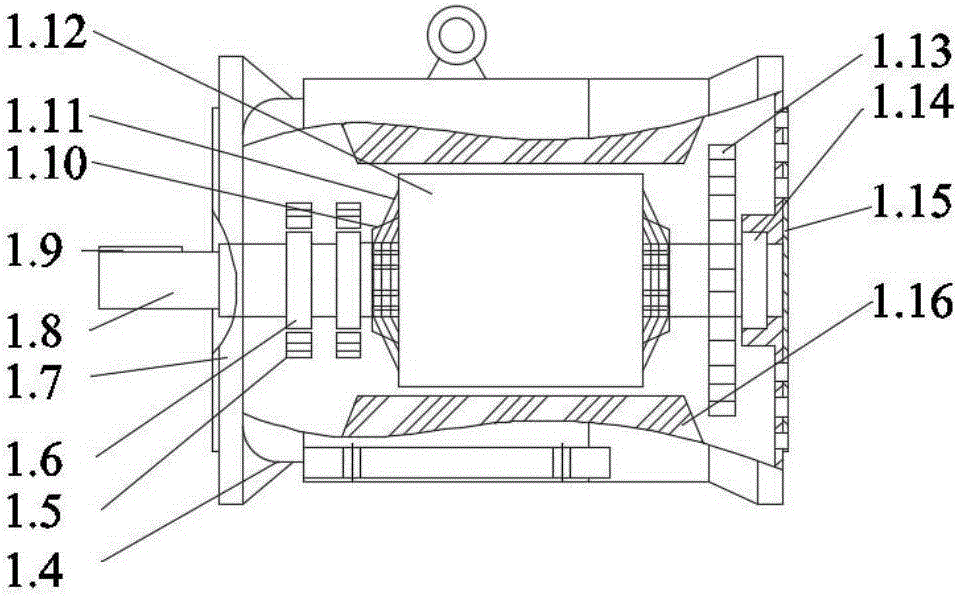

[0024] The power generation device A includes an alternator 1, a voltage regulator 1.3, and a rectifier filter 1.2; wherein the alternator 1 includes a casing 1.4, front and rear end covers 1.7 and 1.15, a fan 1.13, a stator 1.16, a rotor 1.8, a ball bearing 1.14, Conductive slip ring 1.6, electric brush 1.5 and so on. In the cavity formed by the front and rear end covers 1.7 and 1.15 of the alternator 1 and the casing 1.4, the rotor 1.8 is supported by a pair of ball bearings 1.14; the interior of the rotor 1.8 is composed of claw poles 1.10, magnetic field w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com