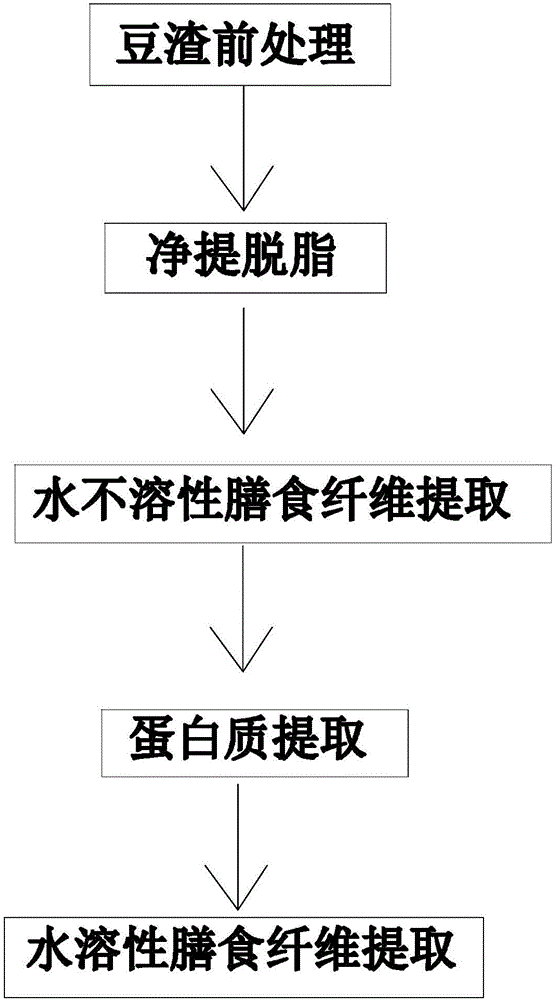

Method of extracting dietary fibers and protein from bean dregs

A dietary fiber and protein technology, applied in the field of chemistry, can solve the problems of single extraction of bean dregs dietary fiber or protein, in the laboratory stage, without systematic research, etc., so as to reduce production costs and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

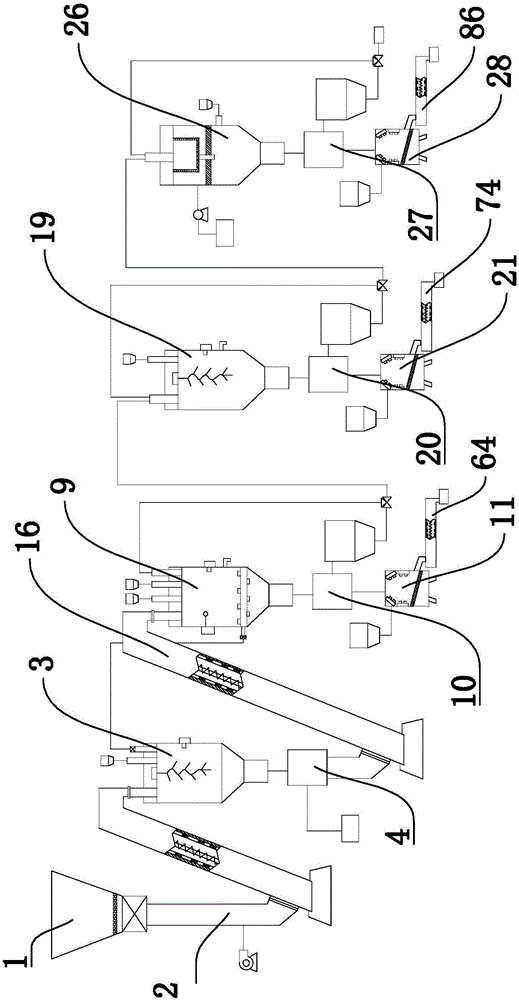

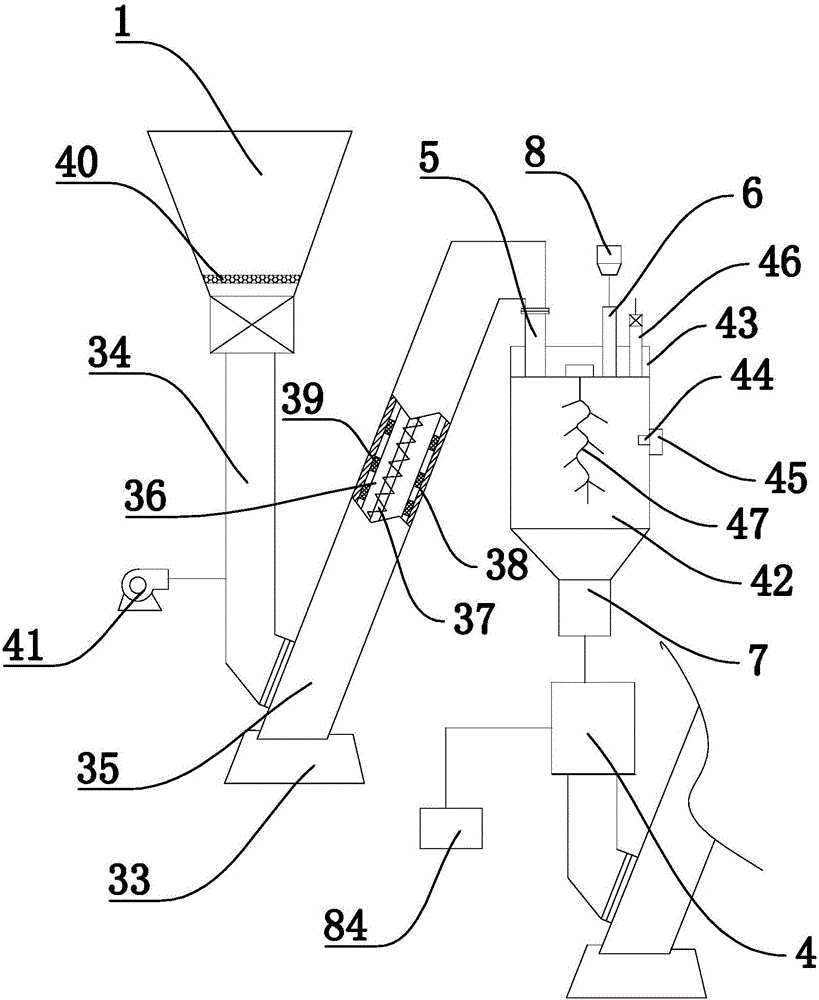

[0031] The method for extracting dietary fiber and protein from bean dregs comprises the following steps:

[0032] 1) Pre-treatment of bean dregs: Put fresh wet bean dregs into grinder 1, after grinder 1 grinds wet bean dregs into bean dregs powder, open the discharge valve at the discharge port of grinder 1, and the discharge valve of the discharge port of grinder 1 The top is provided with a 60-mesh screen 40, and the bean dregs powder falls into the conveying auger-2 after passing through the sieve 40, and starts the motor of the conveying auger-2, which drives the auger shaft 37 to rotate, and the auger shaft 37 sends the bean dregs powder into the feed pipe one 5, while the auger shaft 37 is conveying the bean dregs powder, the electric heater 39 in the conveying auger one 2 is energized, and the electric heater 39 is energized to heat the inside of the conveying auger one 2 to 65°C. The bean dregs powder is dried, and after the dried bean dregs powder falls from the feed...

Embodiment 2

[0038] The method for extracting dietary fiber and protein from bean dregs comprises the following steps:

[0039] 1) Pre-treatment of bean dregs: Put fresh wet bean dregs into grinder 1, after grinder 1 grinds wet bean dregs into bean dregs powder, open the discharge valve at the discharge port of grinder 1, and the discharge valve of the discharge port of grinder 1 The top is provided with a 70-mesh screen 40, and the bean dregs powder falls into the conveying auger-2 after passing through the sieve 40, and the motor of the conveying auger-2 is started, and the motor drives the auger shaft 37 to rotate, and the auger shaft 37 sends the bean dregs powder into the feed pipe one 5, while the auger shaft 37 is conveying the bean dregs powder, the electric heater 39 in the conveying auger one 2 is energized, and the electric heater 39 is energized to heat the inside of the conveying auger one 2 to 70°C. The bean dregs powder is dried, and after the dried bean dregs powder falls f...

Embodiment 3

[0045] The method for extracting dietary fiber and protein from bean dregs comprises the following steps:

[0046] 1) Pre-treatment of bean dregs: Put fresh wet bean dregs into grinder 1, after grinder 1 grinds wet bean dregs into bean dregs powder, open the discharge valve at the discharge port of grinder 1, and the discharge valve of the discharge port of grinder 1 The top is provided with 80 mesh screens 40, and the bean dregs powder falls into the conveying auger-2 after passing through the sieve 40, starts the motor of the conveying auger-2, and the motor drives the auger shaft 37 to rotate, and the auger shaft 37 sends the bean dregs powder into the feed pipe one 5, while the auger shaft 37 is transporting the bean dregs powder, the electric heater 39 in the conveying auger one 2 is energized, and the electric heater 39 is energized to heat the inside of the conveying auger one 2 to 80°C. The bean dregs powder is dried, and after the dried bean dregs powder falls from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com