Phenolic resin integrated superamphiphobic anti-ultraviolet aging coating and preparation method thereof

A technology of anti-ultraviolet aging and phenolic resin, applied in the direction of coating, etc., can solve the problems of difficult to achieve integrated preparation, poor anti-ultraviolet aging performance, and high process requirements, so as to solve the problems of poor anti-aging performance, improve anti-aging performance, use simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

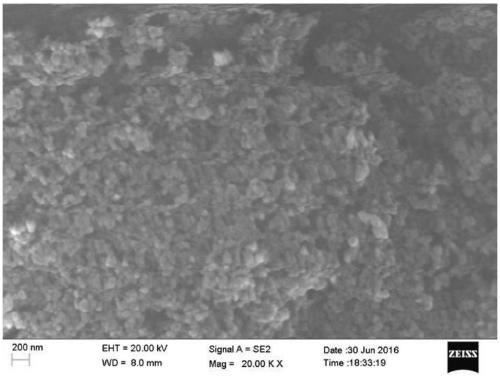

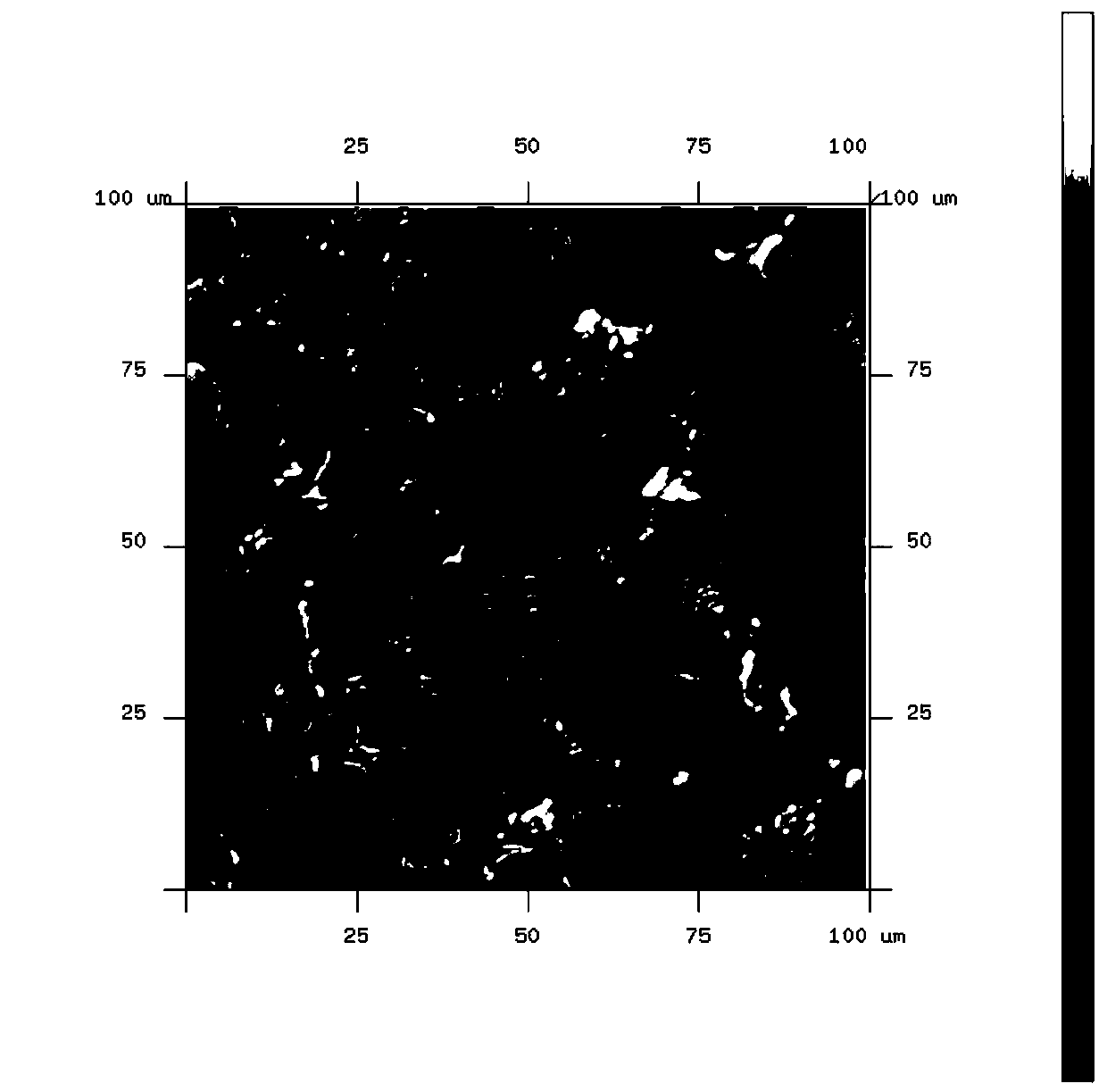

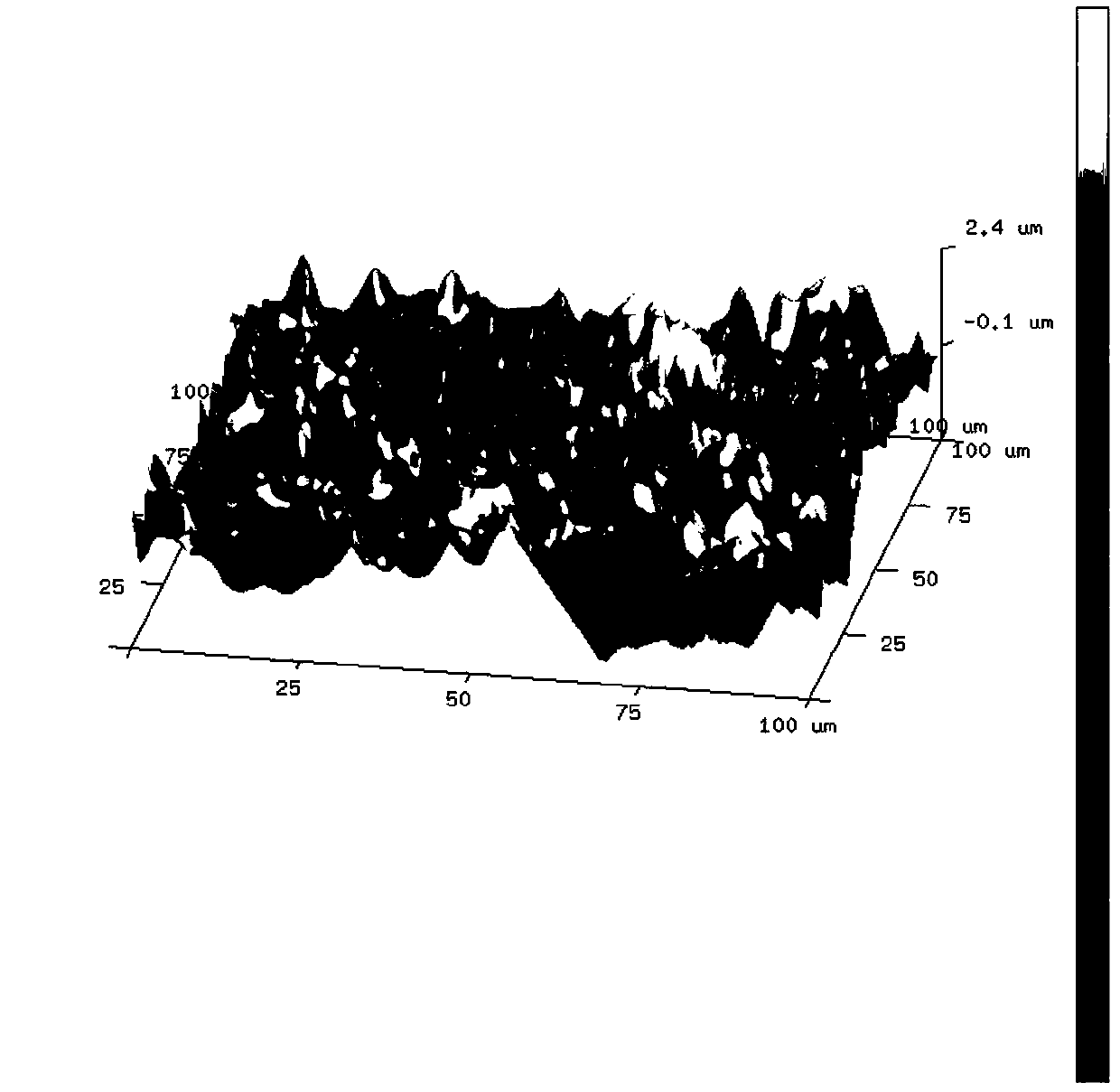

[0052] Embodiment 1: phenolic resin integrated superamphiphobic anti-ultraviolet aging coating, the steps are as follows:

[0053] 1. Mix titanium dioxide nanoparticles with 1H, 2H, 2H-perfluorooctylmethyldichlorosilane at a mass ratio of 1:6, add acetone to dissolve into a gel, and disperse ultrasonically for 20 minutes.

[0054] 2. Mix perfluorosiloxane and tert-butyl acetate at a mass ratio of 1:10, stir magnetically, heat at 100°C, stir at a rate of 1200r / min, and stir for 1.5 hours to obtain mixture 1.

[0055] 3. Add BYK3700 nano additives to octyl-1 methoxy-2 propoxy acetate, the mass ratio of propylene glycol methyl ether acetate to BYK3700 nano additives is 1:5, magnetic stirring, heating temperature Mixture 2 was obtained after stirring for 1 h at 70° C. with a stirring rate of 1000 r / min.

[0056] 4. Mix mixture 1 and mixture 2 at a mass ratio of 1:1 to obtain mixture 5, mix the jelly obtained in step 1 with mixture 5 at a mass ratio of 1:12 and put them into a thr...

Embodiment 2

[0062] Embodiment 2:, phenolic resin integrated superamphiphobic anti-ultraviolet aging coating, the steps are as follows:

[0063] 1. Mix titanium dioxide nanoparticles with 1H, 2H, 2H-perfluorooctylmethyldichlorosilane at a mass ratio of 1:4, add acetone to dissolve into a gel, and disperse ultrasonically for 15 minutes.

[0064] 2. Mix perfluorosiloxane and tert-butyl acetate at a mass ratio of 1:7, stir magnetically, heat at 50°C, stir at a rate of 800r / min, and stir for 1.5h to obtain mixture 1.

[0065] 3. Add BYK3700 nano additives to octyl-1 methoxy-2 propoxy acetate, the mass ratio of propylene glycol methyl ether acetate to BYK3700 nano additives is 1:4, magnetic stirring, heating temperature Mixture 2 was obtained after stirring for 2 h at 50° C. with a stirring rate of 800 r / min.

[0066] 4. Mix mixture 1 and mixture 2 at a mass ratio of 5:1 to obtain mixture 5, mix the jelly obtained in step 1 with mixture 5 at a mass ratio of 1:16 and put it into a three-necked ...

Embodiment 3

[0072] Embodiment 3: phenolic resin integrated superamphiphobic anti-ultraviolet aging coating, the steps are as follows:

[0073] The technical solution adopted by the present invention to achieve the above object is to provide a preparation process for an integrated superamphiphobic anti-ultraviolet aging coating, comprising the following steps:

[0074] 1. Mix titanium dioxide nanoparticles with 1H, 2H, 2H-perfluorooctylmethyldichlorosilane at a mass ratio of 1:2, add acetone to dissolve into a gel, and disperse ultrasonically for 10 minutes.

[0075] 2. Mix perfluorosiloxane and tert-butyl acetate at a mass ratio of 1:5, stir magnetically, heat at 50°C, stir at a rate of 1000r / min, and stir for 0.5h to obtain mixture 1.

[0076] 3. Add BYK3700 nano additives to octyl-1 methoxy-2 propoxy acetate, the mass ratio of propylene glycol methyl ether acetate to BYK3700 nano additives is 2:13, magnetic stirring, heating temperature Mixture 2 was obtained after stirring for 0.5 h a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com