Blast furnace high-aluminum slag smelting method

A high-alumina slag and smelting method technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve problems such as unstable production and high smelting costs of blast furnace molten iron, and achieve the effects of improving air permeability, promoting cost reduction and increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below through specific examples.

[0019] The invention is at 3250m 3 See Table 1 for blast furnace production data, blast furnace smelting control parameters, and blast furnace smelting data in Table 2.

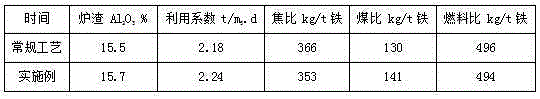

[0020] Table 1 Control parameters of blast furnace smelting in the present invention

[0021]

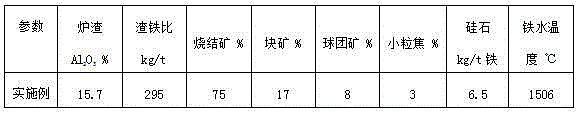

[0022] Table 2 Blast furnace smelting data

[0023]

[0024] As can be seen from Table 2, adopt the method of the present invention, the Al in the blast furnace slag 2 o 3 Even if the mass percentage is increased from 15.5% of the conventional process to 15.7%, the condition of the blast furnace is still stable and smooth, the utilization factor is increased by 2.75% compared with the original, the coke ratio is reduced by 13kg / t iron, and the coal ratio is increased by 11kg / t t iron, the fuel ratio is reduced by 2kg / t iron, and the economic benefit is remarkable.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com