A dust removal module and a gas dust removal device

A gas dedusting and cabinet technology, applied in the direction of solid separation, electrostatic separation, chemical instruments and methods, etc., can solve the problems of ozone secondary pollution, high filtration resistance, etc., and achieve the effect of low purification cost, low energy consumption and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

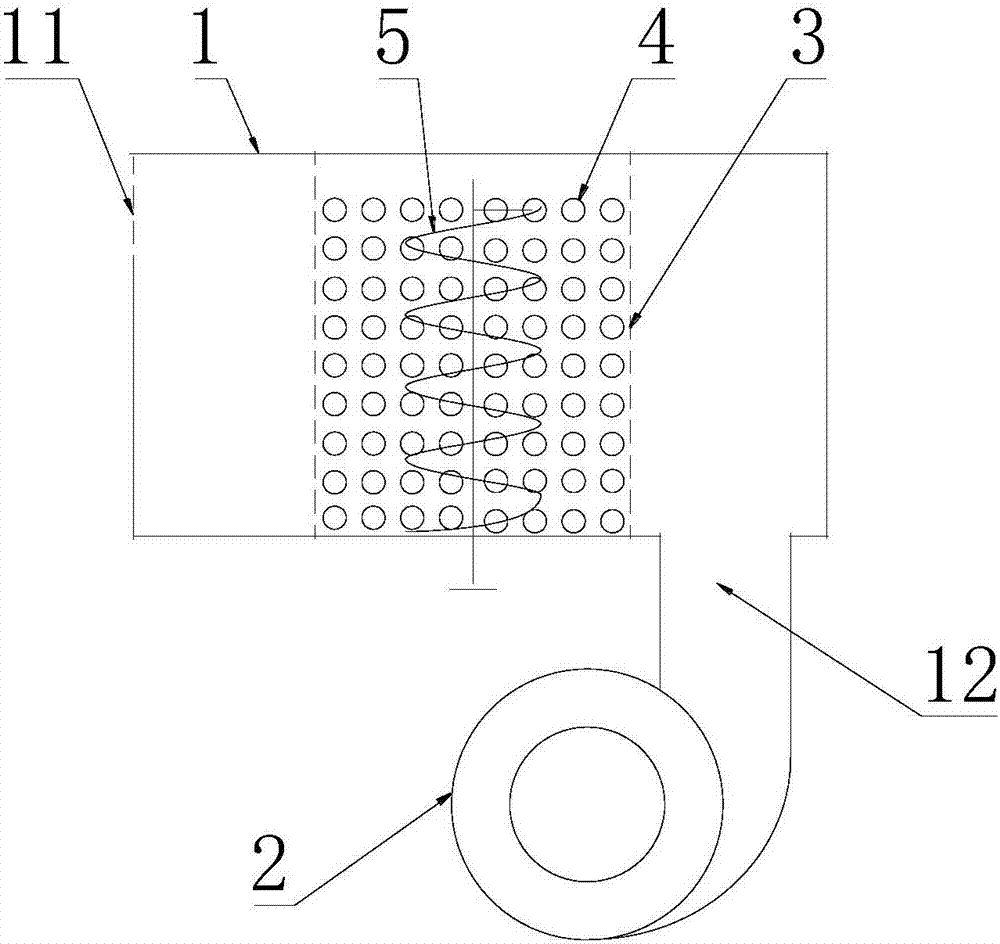

[0031] Such as figure 1 As shown, the present invention provides a dust removal module, which includes an outer cover 3 provided with several ventilation holes, the outer cover 3 is filled with several dust collection units 4, and the outer cover 3 is provided with a The agitator 5; there are at least two different electronegativity between the outer cover 3 and the dust collection unit 4, or the dust collection unit 4 and the agitator 5, or the dust collection unit 4.

[0032] There are at least two kinds of different electronegativity between some dust collection units 4, or dust collection unit 4 and agitator 5, or dust collection unit 4 and outer cover 3, that is to say, dust collection unit 4 and dust collection unit 4 have different electronegativity, dust suction unit 4 and outer cover 3 have different electronegativity, dust suction unit 4 and agitator 5 have different electronegativity, these three situations can exist independently, Any combination is also possible,...

Embodiment 2

[0046] The invention also discloses a gas dedusting device, such as figure 1 As shown, there is a dust removal module as described in Embodiment 1.

[0047] An air inlet 12 can be arranged on one side of the dust removal module, and the gas is guided from the air inlet 12 to pass through the dust removal module, and the purified gas is directly discharged through the vent hole on the outer cover 3 on the other side of the dust removal module. Of course, the air inlet 12 can also be changed to an air outlet 11, that is, only one air outlet 11 is provided, so that the gas passes through the dust removal module first, and then is discharged from the air outlet 11, or is led to a place where clean gas needs to be provided through a pipeline.

[0048] In addition to the above two structures, it is also possible to adopt figure 1 The structure shown: the gas dust removal device also includes: a cabinet 1 with an air inlet 12 and an air outlet 11, the dust removal module is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com