Multifunctional firework bright star granulation safety material preparing mechanism

A multi-functional and granulating technology, applied in the separation of dispersed particles, the use of liquid separators, attack equipment, etc., can solve the problem of no alcohol and powder automatic adding device, no weighing and flow control device, and can not be very good. Control feeding and other issues to achieve the effects of good feeding stability and fluency, large hopper capacity and enhanced safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing, the specific implementation manner of this patent is described in further detail.

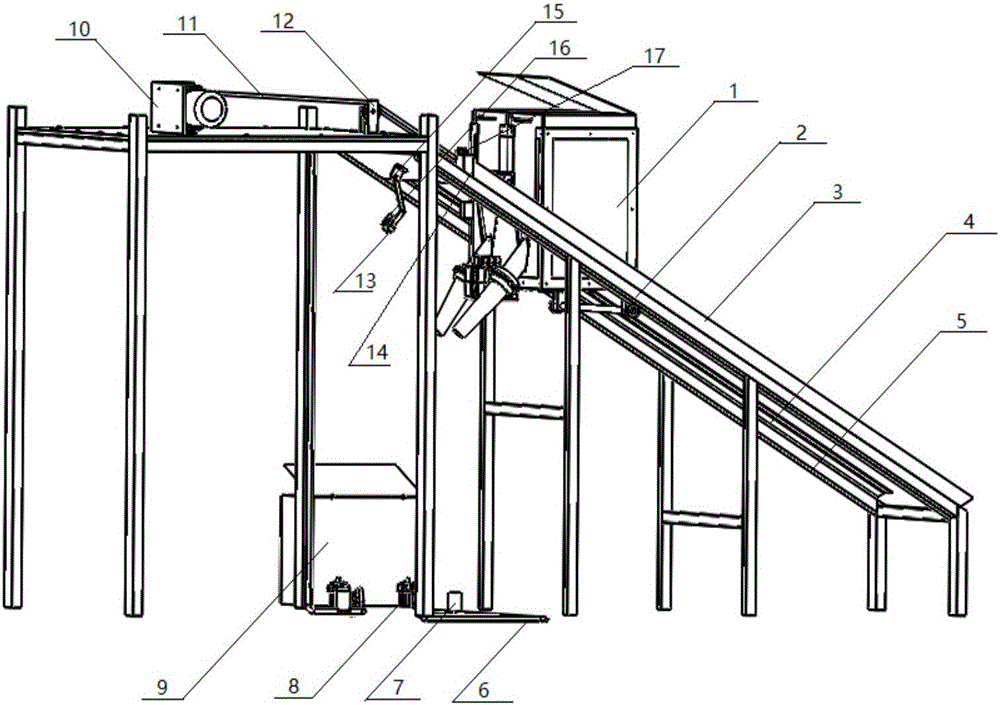

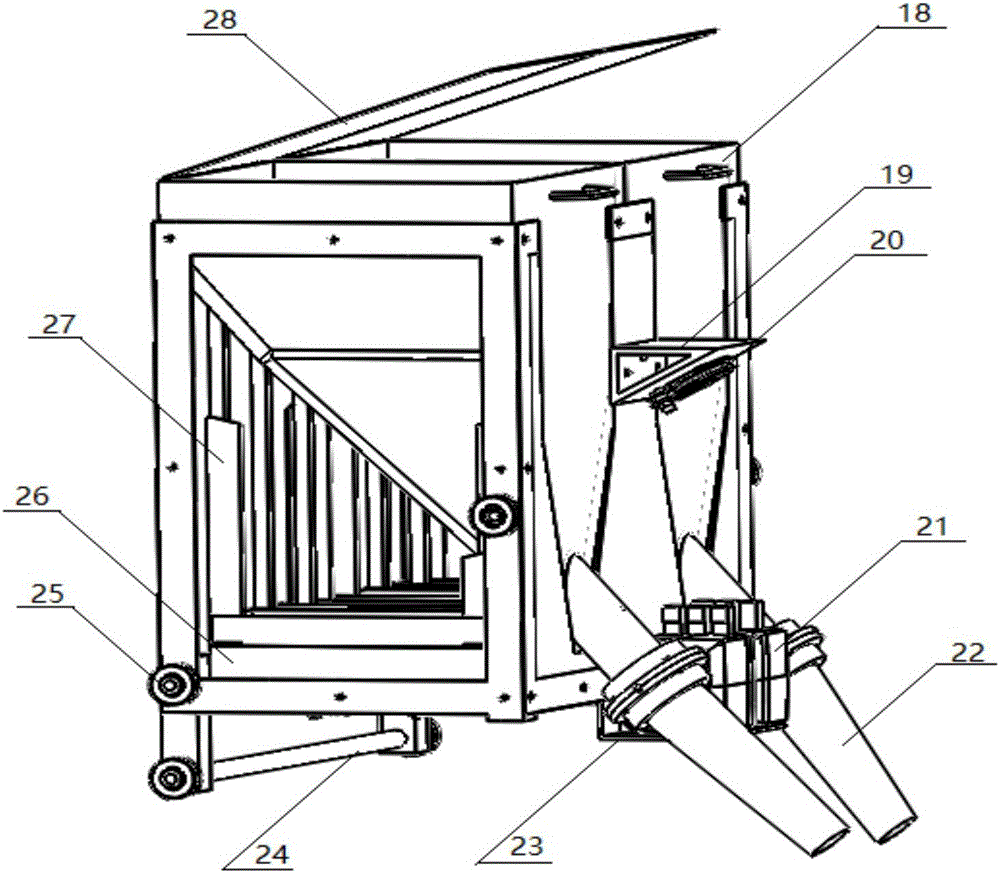

[0035] Such as Figures 1 to 2 As shown, a fireworks bright bead granulation batching mechanism, the batching mechanism includes a frame 2, a multifunctional hoist 10, a steel wire rope 11, a fixed pulley 12, a movable pulley 20, a feeding cart 1, a pipeline 6, and an electric control water valve 7 , water pump 8, water and medicament box 9, nozzle 13, nozzle bracket 15, dust instrument 16. The granulation and batching mechanism adopts simple and efficient wire rope transmission, and through the fixed pulley 12 and the movable pulley 20, it drives the material trolley 1 to move on the frame 2 to achieve the purpose of feeding. The material trolley adopts two wedge-shaped diversion hoppers 18 Respectively hold granular material and powder material, the feed truck adopts a pneumatic butterfly valve 21 as a flow control valve, the feed truck ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com