Film laying anti-seepage salt pan and building method thereof

A salt field and film laying technology, applied in construction, infrastructure engineering, alkali metal chloride and other directions, can solve the problems of easy aging of canvas and ordinary PE film, affecting the production of salt fields, short service cycle, etc., to prevent leakage of salt fields, The effect of strong plasticity and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This embodiment is carried out in a salt field with a length and width of 2000m×1000m, and the film laying time is high temperature in summer, and the length and width of the HDPE film used are 100m×8m.

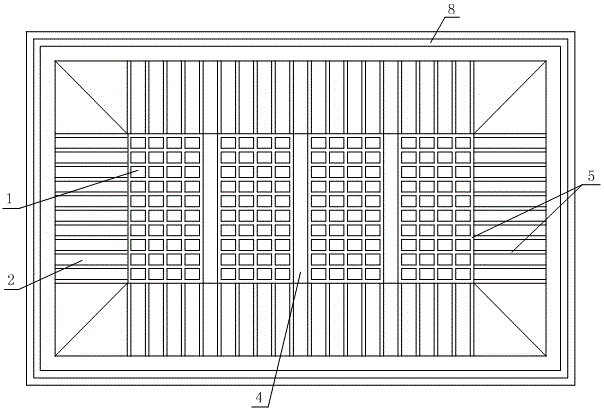

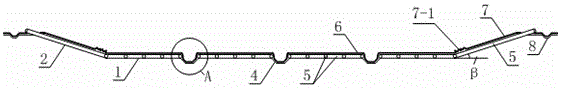

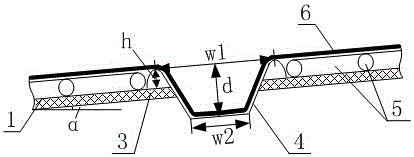

[0044] Such as Figure 1~3 Shown, a kind of film-laying anti-seepage salt pan is formed by surrounding the salt pan bottom 1 and the side slope 2, and a 45cm thick NaCl pool plate 3 is provided on the salt pan bottom 1; parallel to the short side of the salt pan, The bottom surface of the salt pan 1 is excavated with a brine guide ditch 4 every 500m, which divides the salt pan into blocks; on the bottom surface 1 of each single brine pan divided by the brine guide ditch 4, paved in parallel vertically and horizontally every 50m Exhaust pipe 5 is laid in parallel on the Yantian slope 2 every 80m. One end of the exhaust pipe 5 communicates with the exhaust pipe at the bottom of the Yantian, and the other end (exhaust end) extends out of the Yantian slope 2; A salt pan b...

Embodiment 2

[0055] This embodiment is carried out in a salt field with a length and width of 1000m×1000m, and the film laying time is in low temperature winter weather, and the length and width of the film used are 80m×6m.

[0056] Such as Figure 1~3 Shown, a kind of film-laying anti-seepage salt pan is surrounded by salt pan bottom surface 1 and side slope 2 and forms, is provided with 40cm thick NaCl pool plate 3 in described salt pan bottom surface 1; Parallel to the short side of described salt pan, in The brine guide ditch 4 is excavated every 300m on the bottom of the salt pan, and the salt pan is divided into blocks; on the bottom surface 1 of each single salt pan formed by the brine guide ditch 4, the brine guide ditch 4 is laid in parallel vertically and horizontally every 120m. Exhaust pipe 5 is laid in parallel on the Yantian slope 2 every 100m. One end of the exhaust pipe 5 communicates with the exhaust pipe at the bottom of the Yantian, and the other end (exhaust end) extend...

Embodiment 3

[0067] This embodiment is carried out in a salt field with a length and width of 4000m×1000m, and the film laying time is in low temperature winter weather, and the length and width of the film used are 100m×8m.

[0068] Such as Figure 1~3 Shown, a kind of film-laying anti-seepage salt pan is formed by surrounding the salt pan bottom 1 and the side slope 2, and a 10cm thick NaCl pool plate 3 is provided on the salt pan bottom 1; parallel to the short side of the salt pan, The bottom of the salt pan 1 is excavated with a brine guide ditch 4 every 500m, and the salt pan is divided into blocks; each piece of the single salt pan bottom 1 divided by the brine guide ditch 4 is laid in parallel vertically and horizontally every 200m. Exhaust pipe 5 is laid in parallel on the Yantian slope 2 every 120m. One end of the exhaust pipe 5 communicates with the exhaust pipe at the bottom of the Yantian, and the other end (exhaust end) extends out of the Yantian slope 2; A salt pan bottom f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com