A kind of preparation method of cyclohexane carboxylate

A technology of cyclohexane carboxylate and alkyl ester, applied in the direction of carboxylate preparation, organic compound preparation, chemical instruments and methods, etc., can solve the complex catalyst preparation process, the easy loss of active components, and the amount of waste water generated Large and other problems, to achieve the effect of excellent catalytic activity, easy loading, and uniform pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Weigh 150g metal nickel, 120g metal cobalt, 60g metal manganese, 280g metal aluminum and 50g silicon simple substance, add these metals in the furnace cavity of intermediate frequency induction furnace (purchased from Suzhou Hengfu Vacuum Technology Co., Ltd.), heat and melt at 1600 ° C, separate The batches were poured into a 10cm×10cm mold, and smelted to form a Ni-Co-Mn-Al-Si alloy sheet with a thickness of about 2mm.

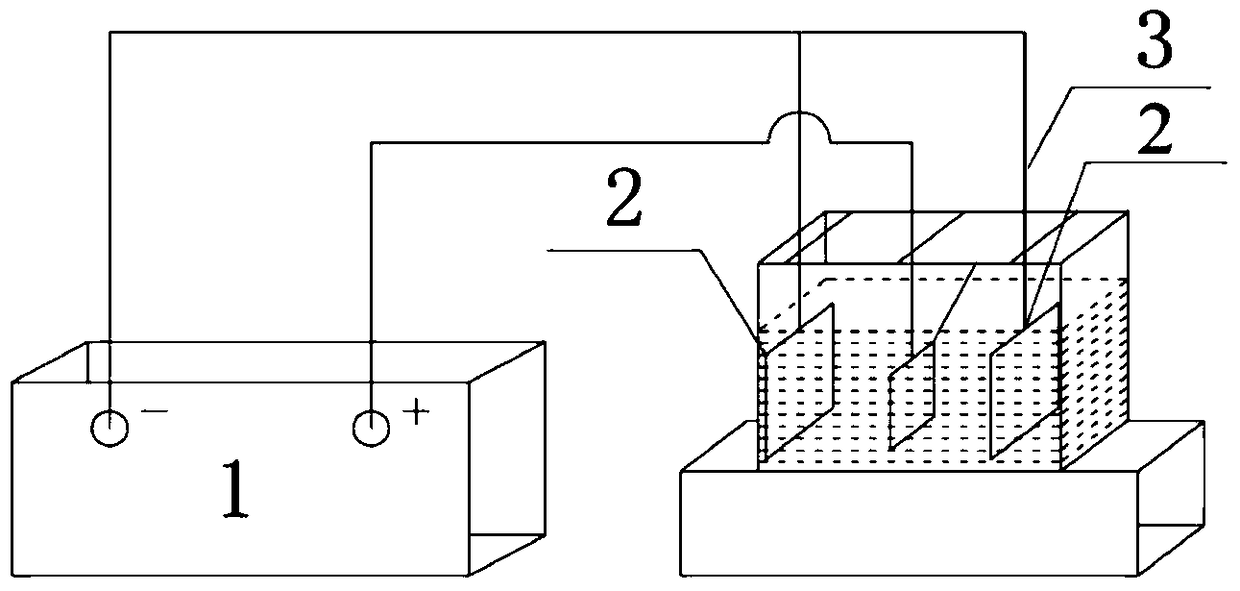

[0040] Formulated with 1wt% NaNO 3 , 2000g glycerol solution of 2.8v% distilled water is used as electrolyte, such as figure 1 The shown device; the Ni-Co-Mn-Al-Si alloy sheet with a thickness of 2mm and a size of 10cm×10cm is used as the anode 3, high-purity graphite is used as the cathode 2, and the area ratio of the anode and cathode is 1:1.2. The distance is set to 4.5cm, the voltage of DC stabilized power supply 1 is 25V, and the additives (NH 4 ) 2 HPO 4 Add it into the electrolyte, the molar ratio of the total amount to the distilled water ...

Embodiment 2

[0042] Weigh 110g metal nickel, 80g metal cobalt, 50g metal manganese, 220g metal aluminum, 10g metal copper and 50g silicon simple substance, these metals are added in the furnace cavity of intermediate frequency induction furnace (purchased in Suzhou Hengfu Vacuum Technology Co., Ltd.), Heated and melted at 1800°C, poured into a 10cm×10cm mold in batches, and smelted to form a Ni-Co-Mn-Cu-Al-Si alloy sheet with a thickness of about 2mm.

[0043] Formulated with 1.5wt% NH 4 NO 3 , 2000g butanediol solution of 2v% distilled water is used as electrolyte, such as figure 1 The device shown is a Ni-Co-Mn-Cu-Al-Si alloy sheet with a thickness of 2mm and a size of 10cm×10cm as the anode 3, metal platinum as the cathode 2, and the area ratio of the anode to the cathode is 1:1.5. The distance between them is set to 4.5cm, the voltage of DC stabilized power supply 1 is 35V, and the additive Na 2 HPO 4 Add it into the electrolyte, the molar ratio of the total amount to the distilled...

Embodiment 3

[0045] Weigh 150g metallic nickel, 125 gram metallic cobalt, 50g metallic manganese, 125g metallic aluminum, 10 gram metallic iron and 40g silicon simple substance, these metals are added in the furnace cavity of intermediate frequency induction furnace (purchased in Suzhou Hengfu Vacuum Technology Co., Ltd.), Heat and melt at 1700°C, pour into a 10cm×10cm mold in batches, and melt to make a Ni-Co-Mn-Fe-Al-Si alloy sheet with a thickness of about 2mm.

[0046] Formulated with 2wt% KNO 3 , 1500g diethylene glycol solution of 2v% distilled water is used as the electrolyte, such as figure 1 The shown device; the thickness is 2mm, the size is 10cm×10cmNi-Co-Mn-Fe-Al-Si alloy sheet is used as anode 3, platinum is used as cathode 2, and the area ratio of anode and cathode is 1:1.4. The distance is set to 5cm, the voltage of the DC stabilized power supply 1 is 25V, and the additive NaH 2 PO 4 Add it into the electrolyte, the molar ratio of the total amount to the distilled water i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com