Patents

Literature

39 results about "Cyclohexane carboxylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

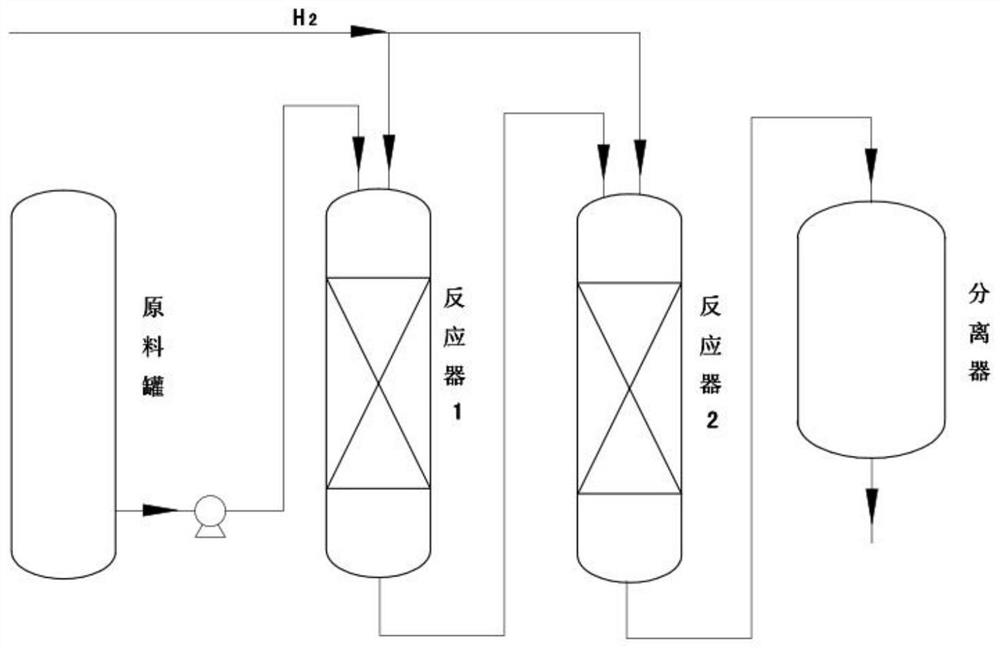

Catalyst for production of cyclohexylcarboxylate by phenylcarboxylate hydrogenation and its preparation method and use

ActiveCN102658146AHigh activityHigh selectivityOrganic compound preparationCarboxylic acid esters preparationActive componentHigh activity

The invention discloses a catalyst for production of cyclohexylcarboxylate by phenylcarboxylate hydrogenation and its preparation method and use. The catalyst comprises 5 to 50wt% of an active component Ni, 0.1 to 25wt% of at least one auxiliary agent and the balance a carrier. The catalyst has the advantages of low price and very high activity and selectivity.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

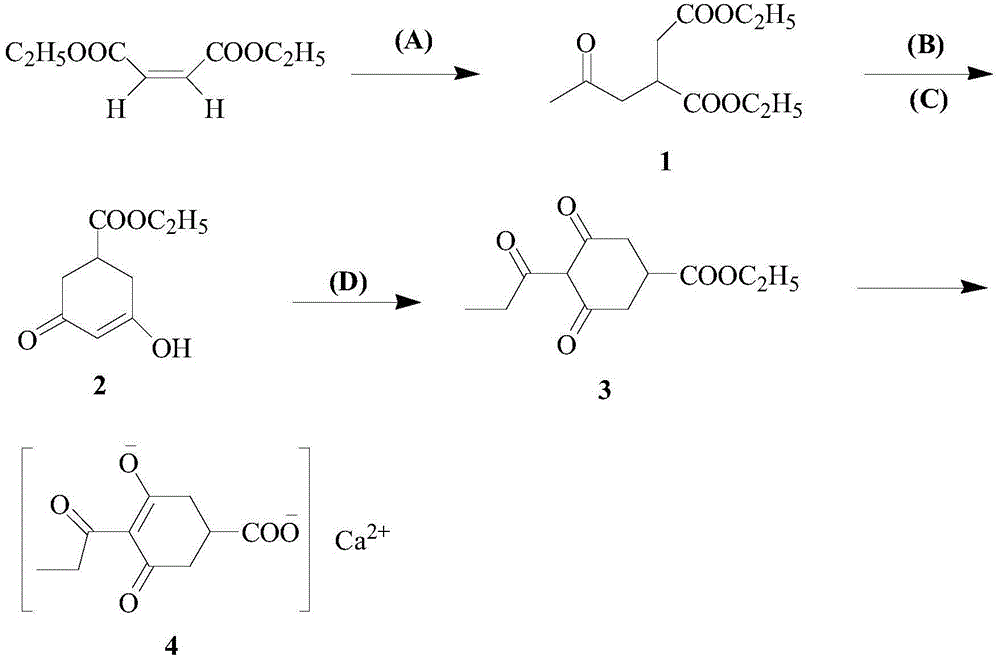

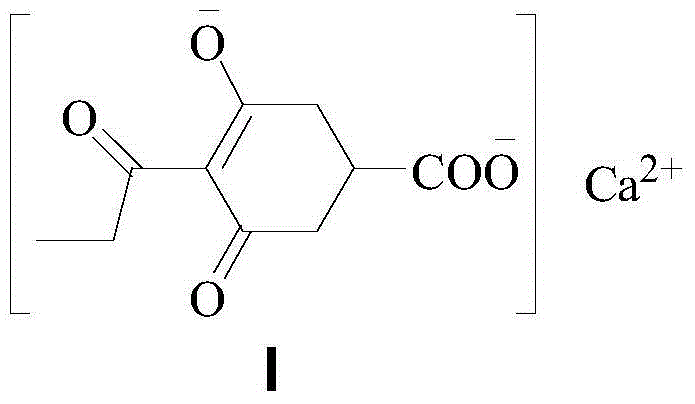

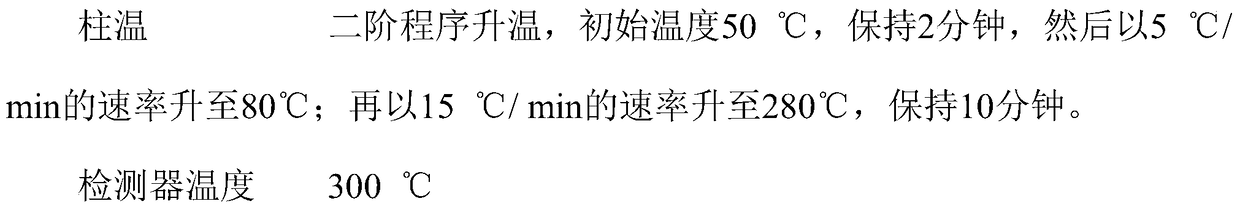

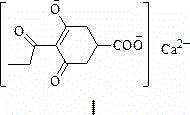

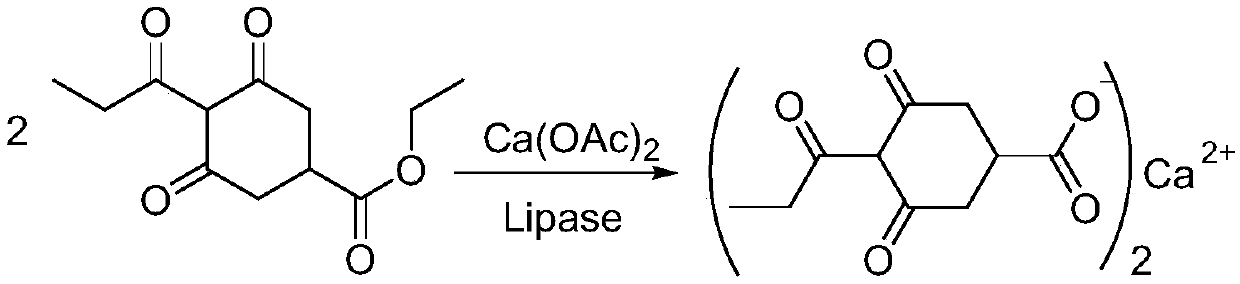

Method for preparing calcium3-oxido-5-oxo-4-propionyl cyclohex-3-enecarboxylate

ActiveCN104140368AReduce manufacturing costSuitable for industrial productionOrganic compound preparationCarboxylic acid esters preparationClaisen condensationOrganic base

Owner:JIANGXI AGRICULTURAL UNIVERSITY

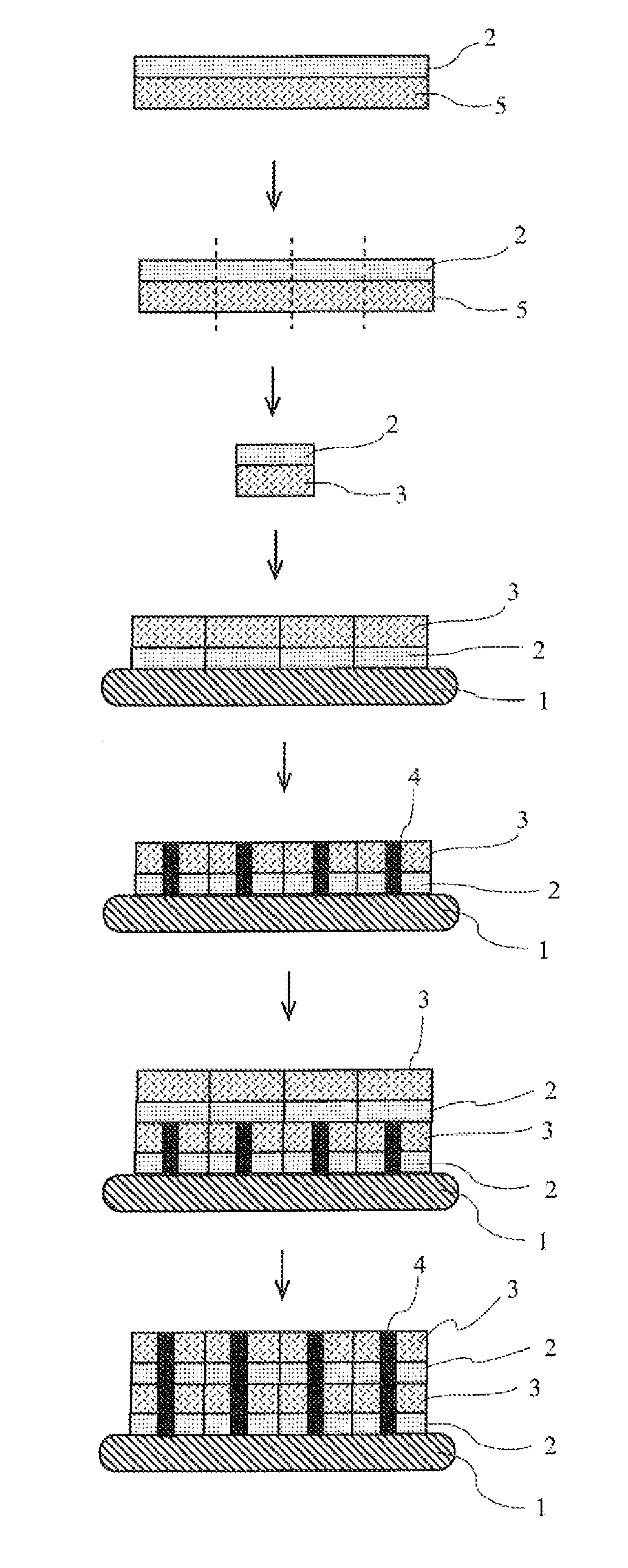

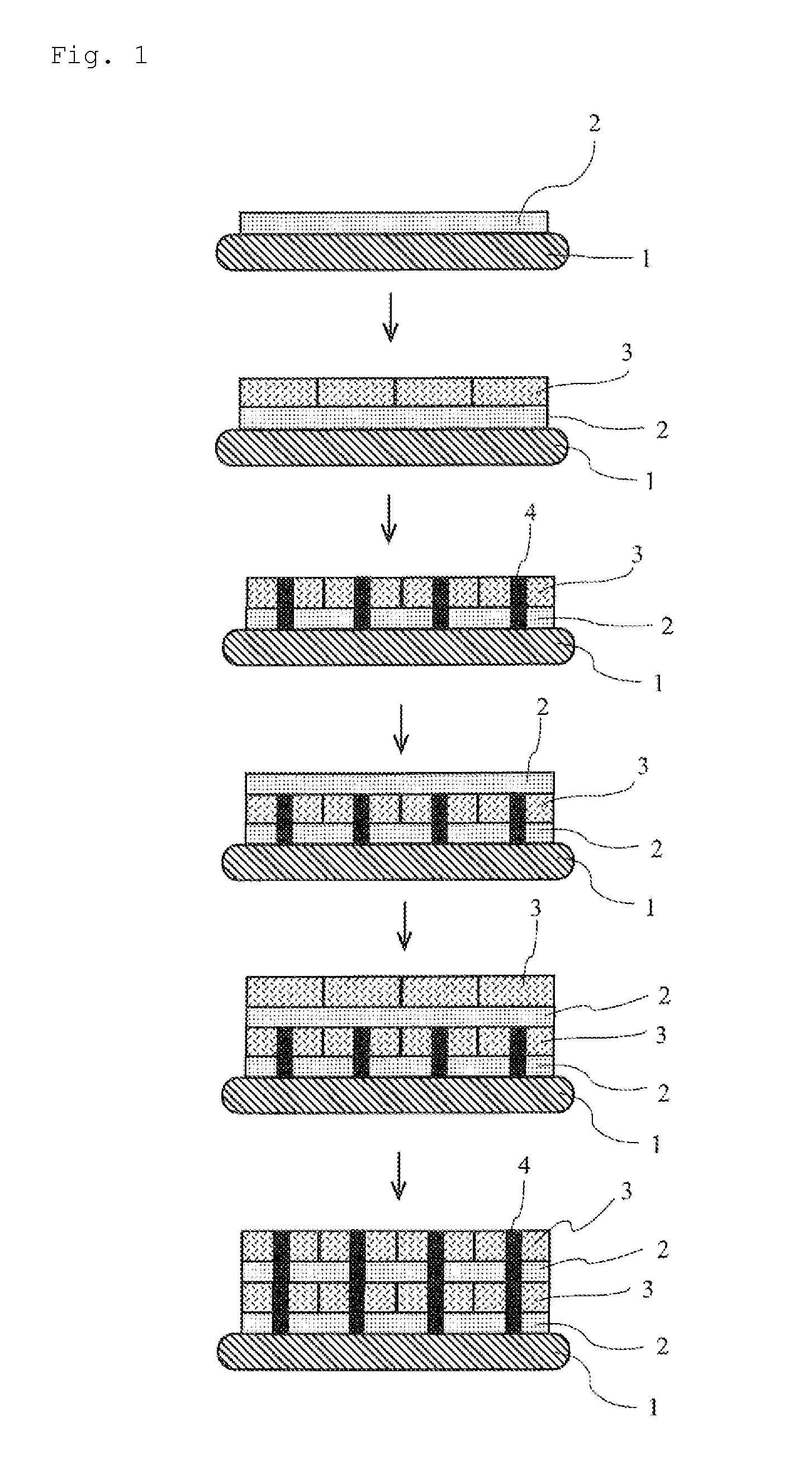

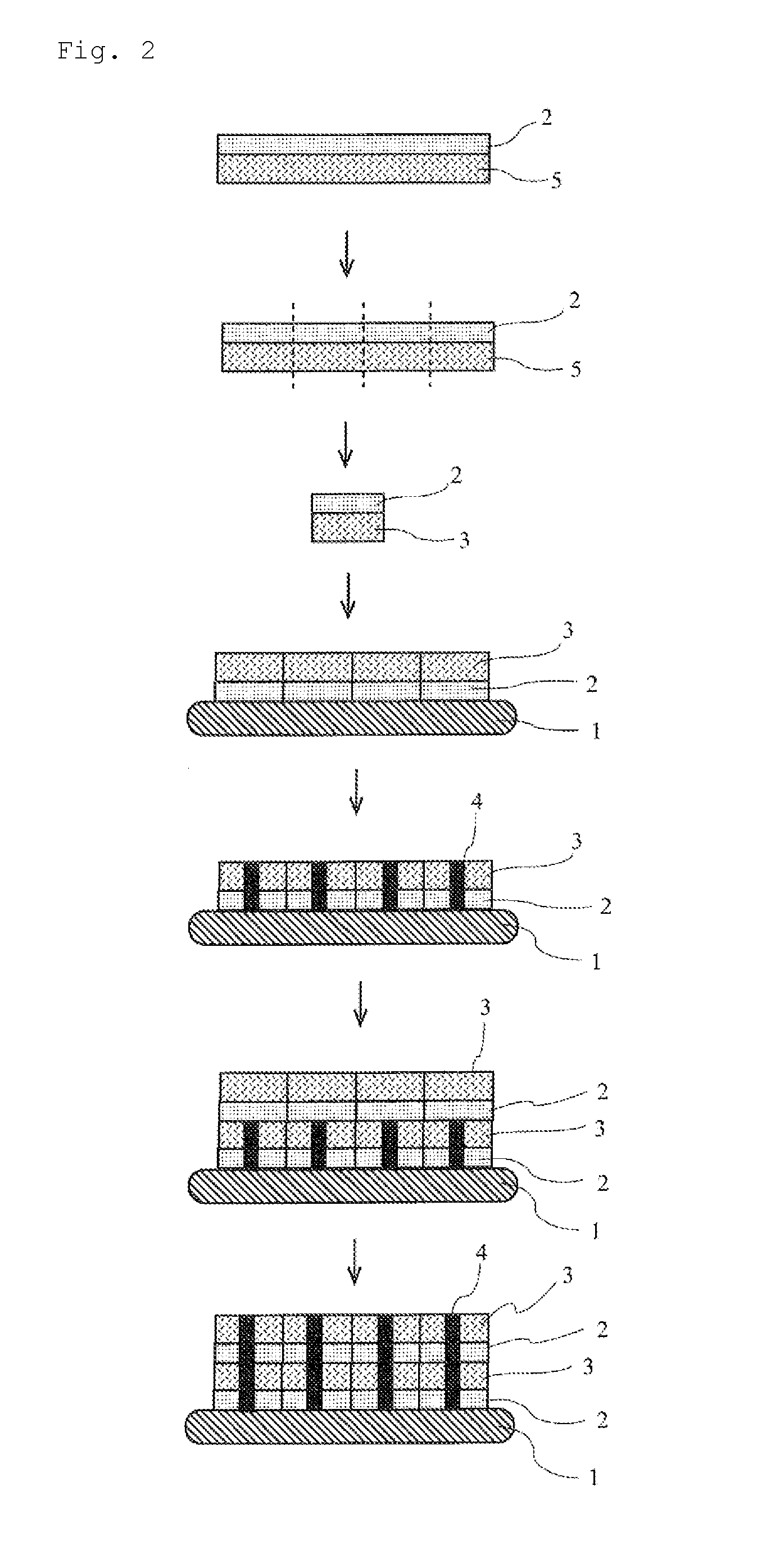

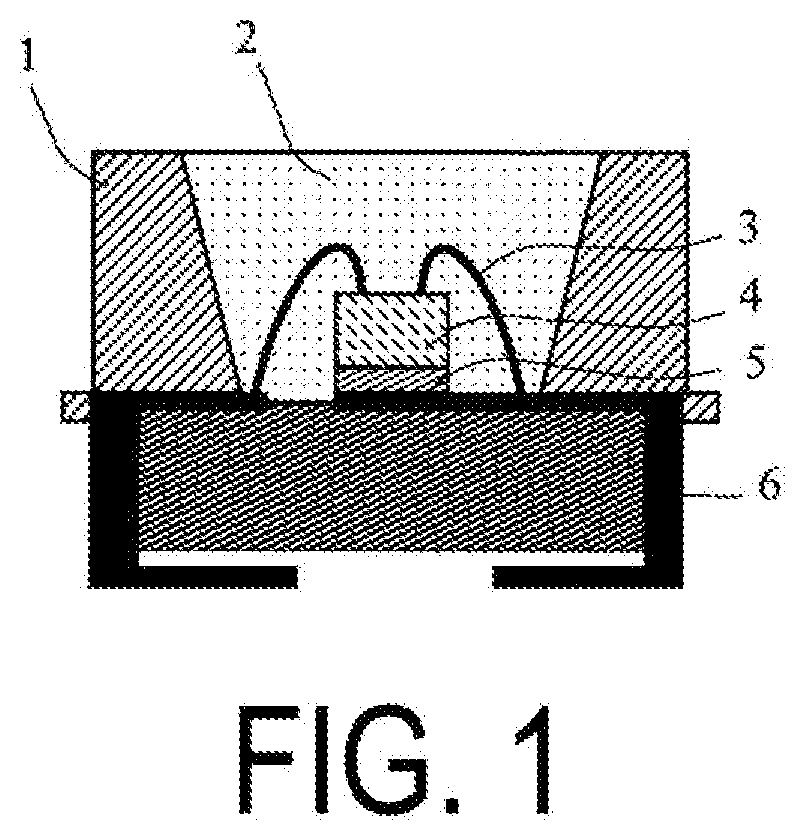

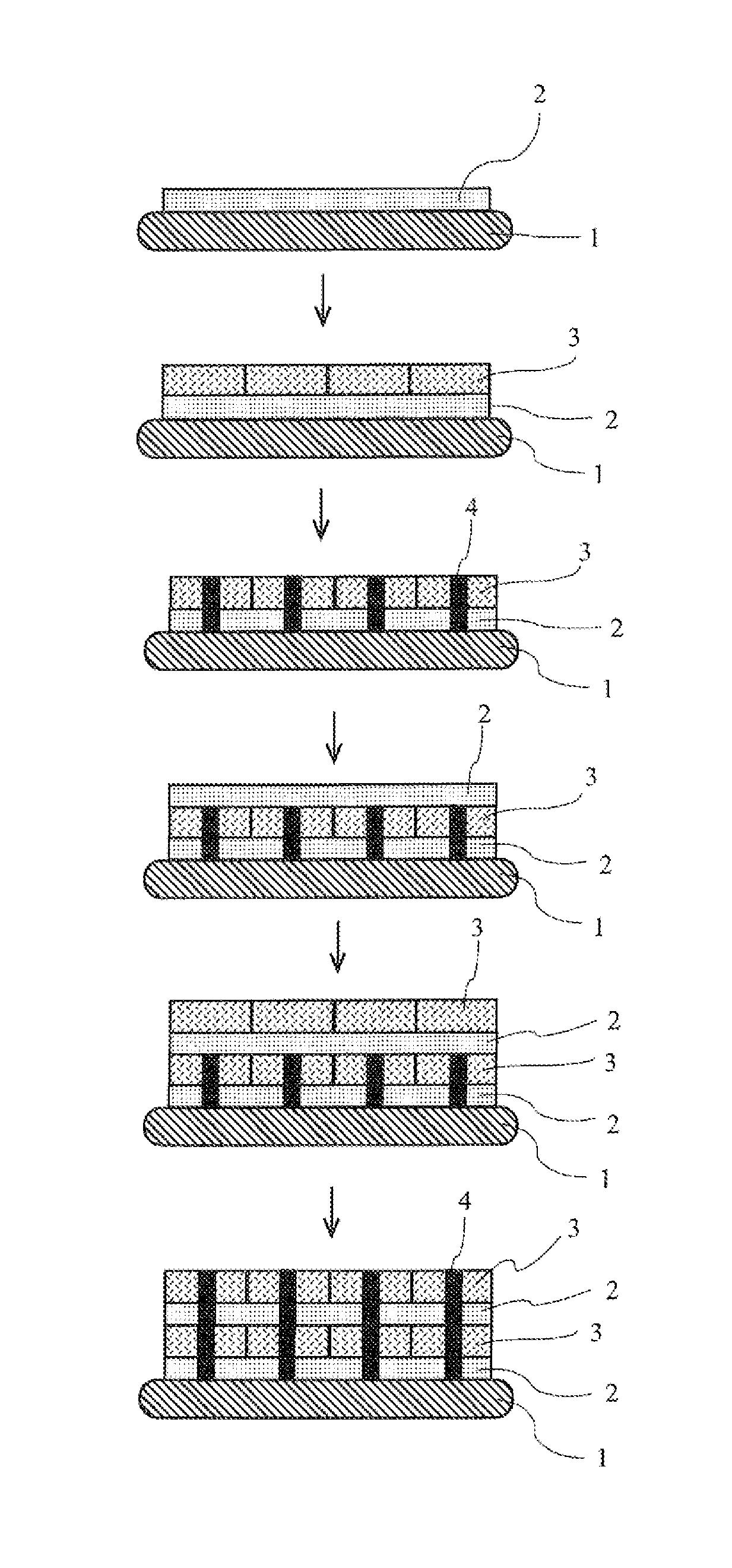

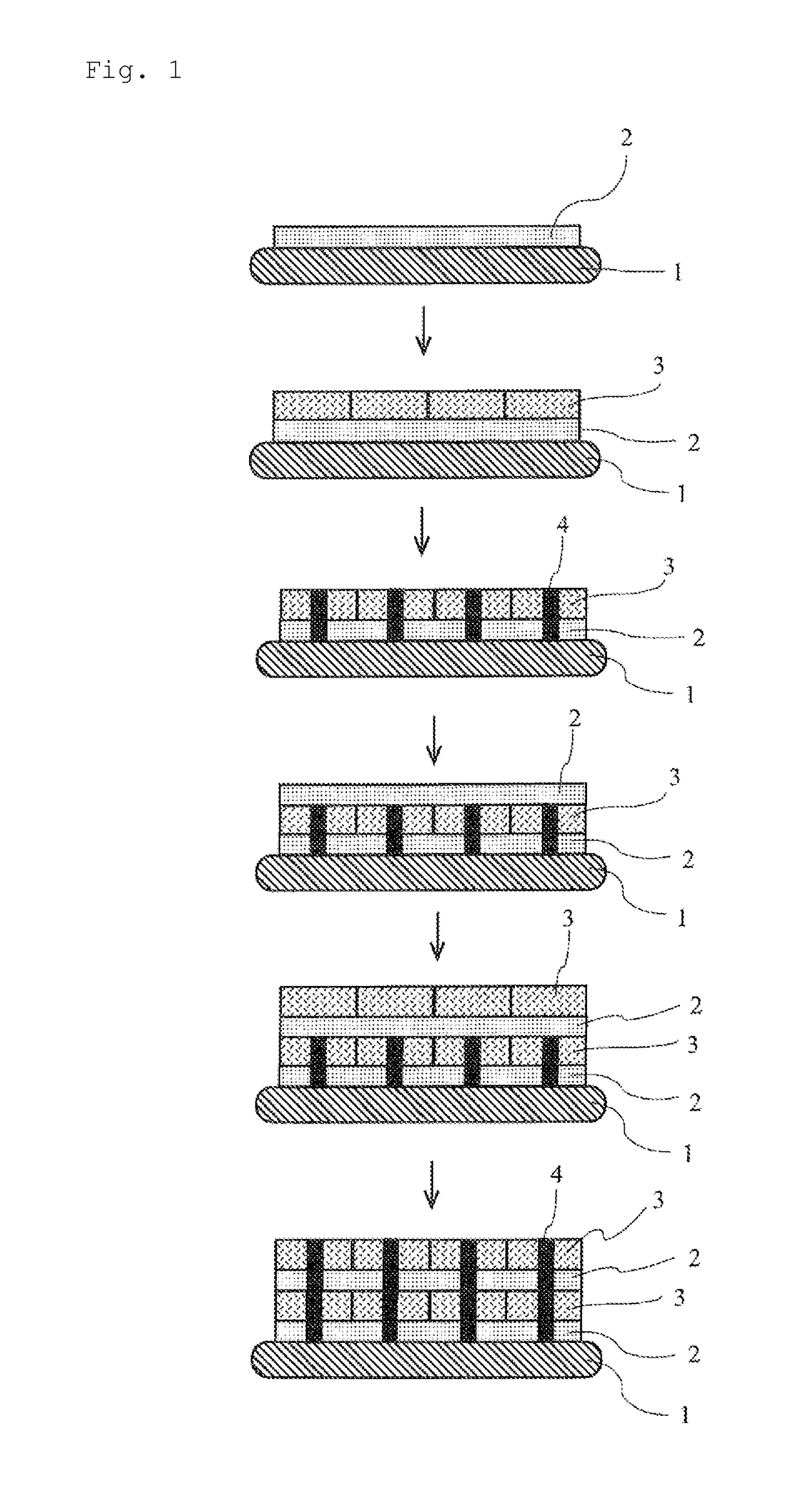

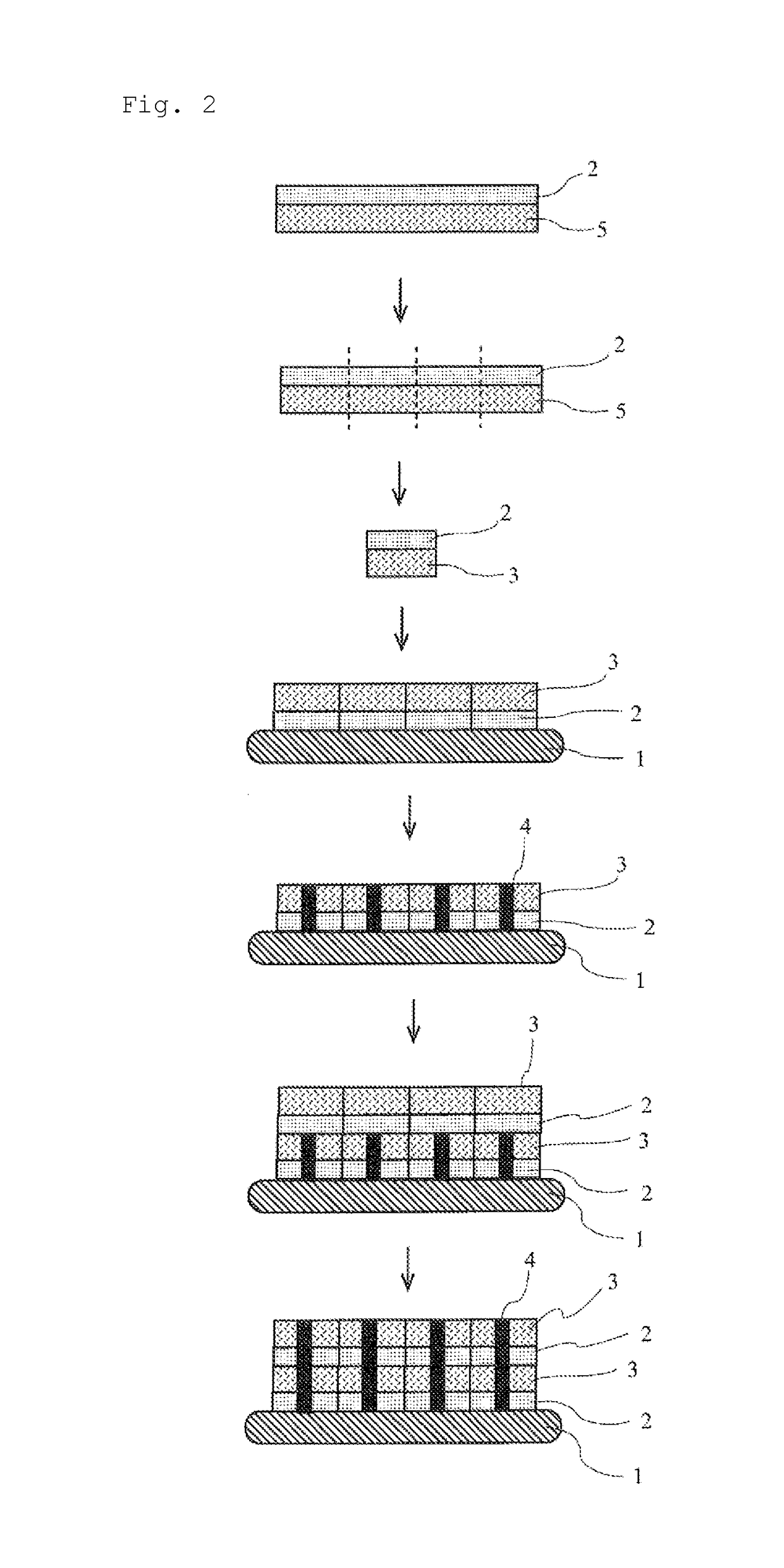

Adhesive agent composition for multilayer semiconductor

InactiveUS20160215183A1Less progressEasy to cutSemiconductor/solid-state device detailsSolid-state devicesCationic polymerizationSemiconductor chip

Provided is an adhesive composition for multilayer semiconductors. The adhesive composition gives, when applied and dried by heating, an adhesive layer that has approximately no adhesiveness at a temperature lower than 50° C., but, when heated at such a temperature as to less cause damage to semiconductor chips, offers adhesiveness and is rapidly cured thereafter. This adhesive composition for multilayer semiconductors includes a polymerizable compound (A), at least one of a cationic-polymerization initiator (B1) and an anionic-polymerization initiator (B2), and a solvent (C). The polymerizable compound (A) contains 80% by weight or more of an epoxide having a softening point or melting point of 50° C. or higher. The cationic-polymerization initiator (B1) gives a composition having a thermal curing time of 3.5 minutes or longer at 130° C., where the composition contains 1 part by weight of the cationic-polymerization initiator (B1) and 100 parts by weight of 3,4-epoxycyclohexylmethyl (3,4-epoxy)cyclohexanecarboxylate. The anionic-polymerization initiator (B2) gives a composition having a thermal curing time of 3.5 minutes or longer at 130° C., where the composition contains 1 part by weight of the anionic-polymerization initiator (B2) and 100 parts by weight of bisphenol-A diglycidyl ether.

Owner:DAICEL CHEM IND LTD

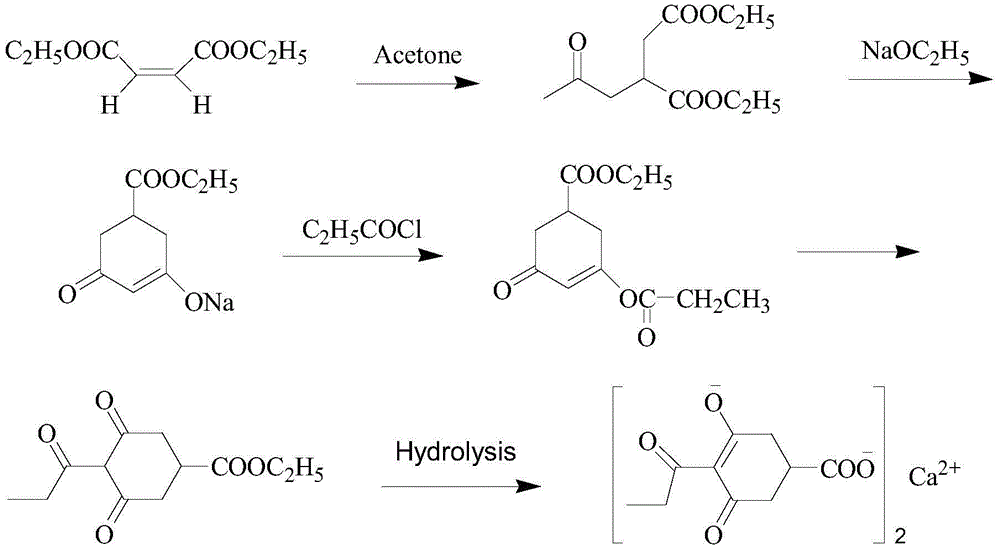

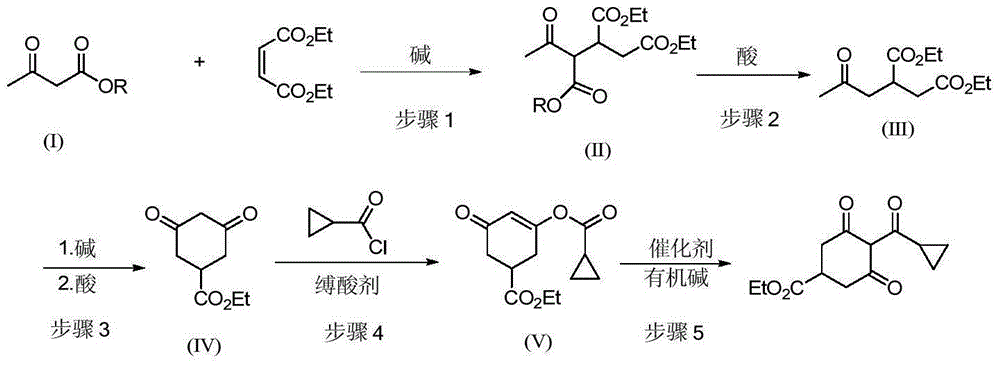

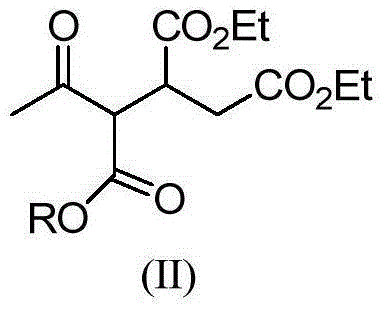

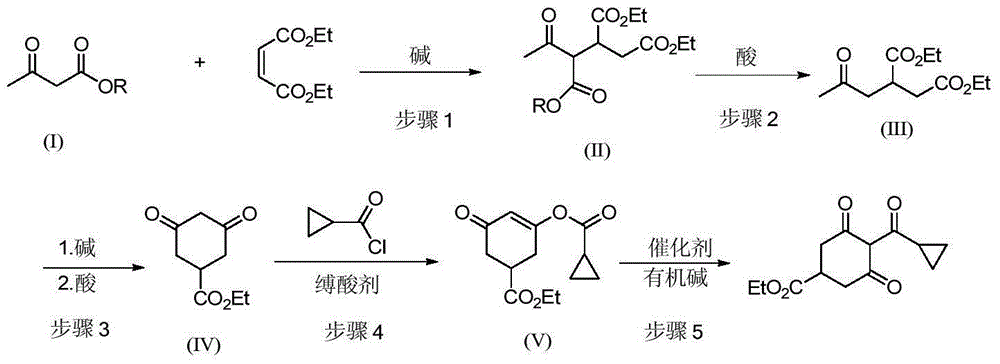

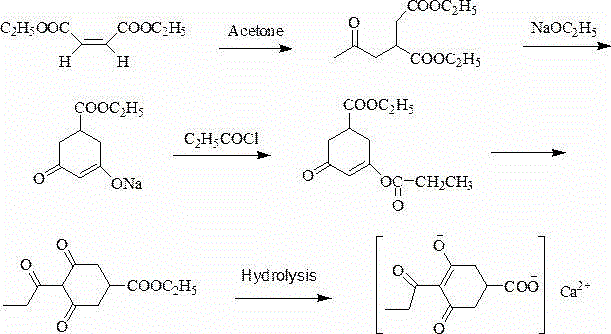

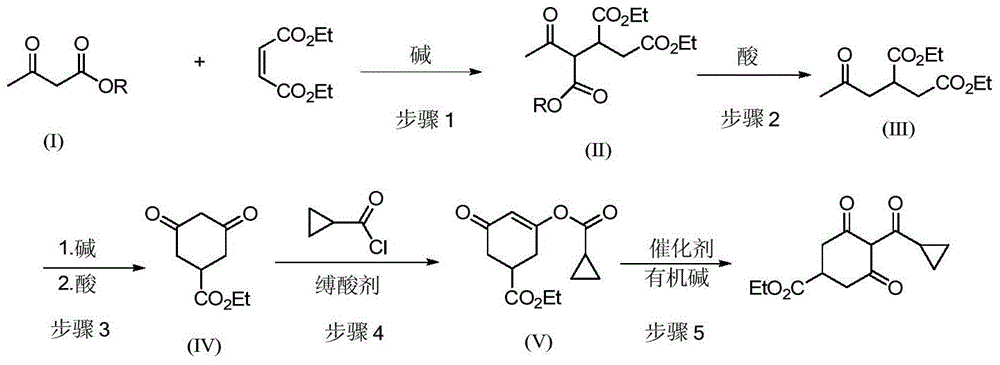

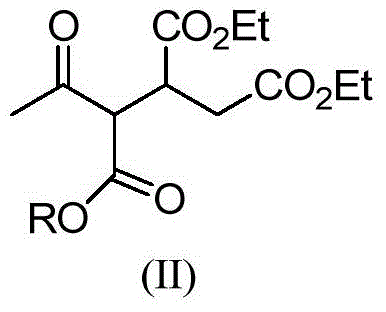

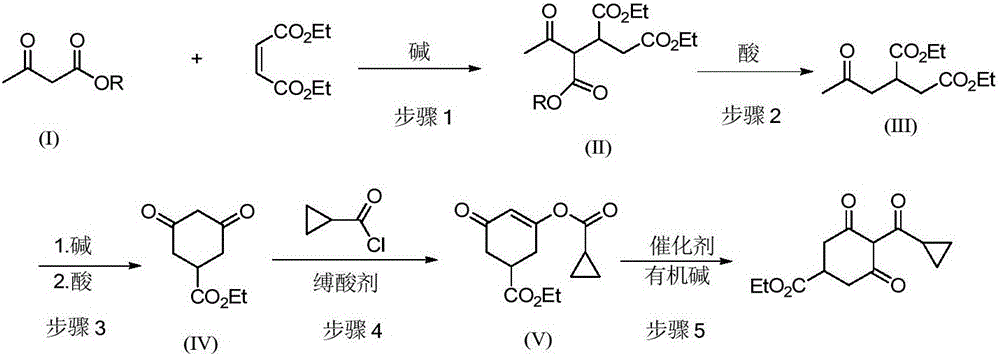

Preparation method of trinexapac-ethyl and intermediate thereof

ActiveCN105085270AImprove qualityGood process reaction selectivityOrganic compound preparationCarboxylic acid esters preparationAcetoacetatesFormate

The invention discloses a preparation method of trinexapac-ethyl and an intermediate thereof. The method comprises the following steps: under the action of an alkali, reacting acetoacetic ester (I) with diethyl maleate to obtain an intermediate (II), continuing reaction under the action of an acid to obtain diethyl 2-acetonyl-1,4-succinate; cyclizing the diethyl 2-acetonyl-1,4-succinate in the presence of an alkali, and acidifying to obtain ethyl 3,5-cyclohexyldione-formate; esterifying the ethyl 3,5-cyclohexyldione-formate and cyclopropyl formyl chloride in the presence of an acid-binding agent to obtain ethyl 4-cyclopropylformacyl-3,5-dione cyclohexane-carboxylate; and carrying out reaction on the end product under the actions of an organic alkali and a catalyst to obtain the trinexapac-ethyl. The technique has the advantages of favorable reaction selectivity, high yield and fewer byproducts, and is beneficial to obtaining the high-quality trinexapac-ethyl product. The method does not have high requirements for equipment, and avoids high-temperature high-pressure reaction. The method has the advantages of simple technique and mild reaction conditions, and is suitable for industrialization.

Owner:MAX RUDONG CHEM

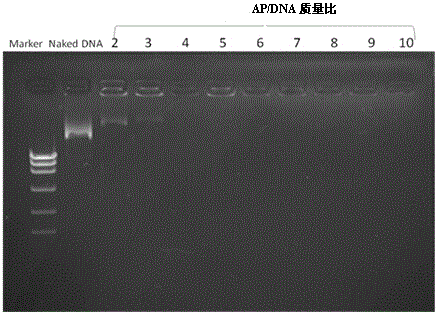

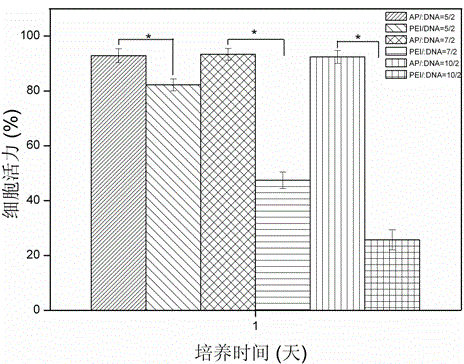

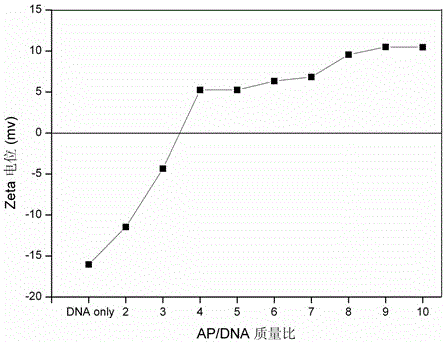

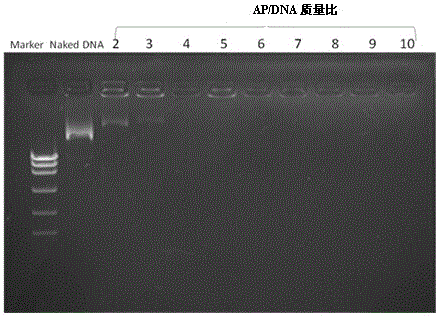

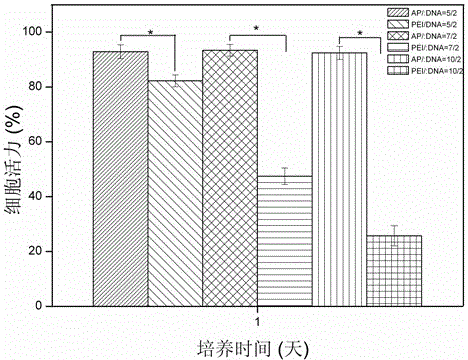

Cationization silk fibroin and preparation method thereof

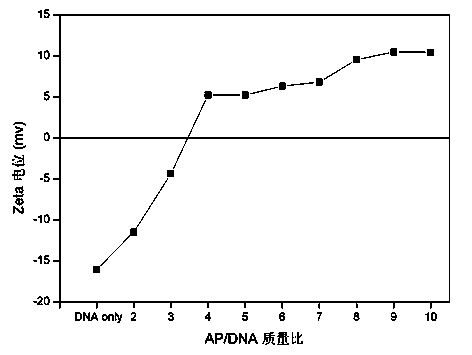

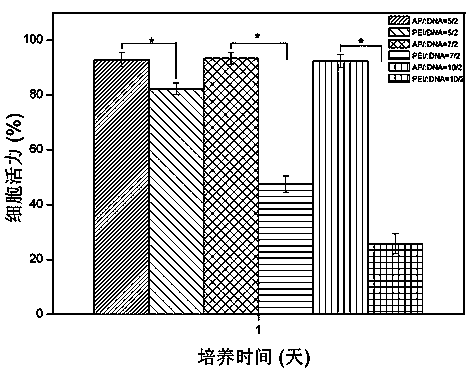

ActiveCN104119451AGuaranteed biodegradabilityImprove targetingPeptide preparation methodsOther foreign material introduction processesGene deliveryCarboxylic acid

The invention discloses a cationization silk fibroin and a preparation method thereof, and belongs to the technical field of medical high-molecular materials. The cationization silk fibroin is obtained through reaction by coupling protamine sulfate mediated by water-soluble 2-imido thiacyclopentane hydrochloride with silk fibroin activated by sulfo-succinimido-4-[N-maleimide methyl]-cyclohexane-1-carboxylate. The cationization silk fibroin disclosed by the invention has the advantages of good biocompatibility and degradability, controllability in surface charge density, effective DNA (Deoxyribonucleic Acid) compression and protection capacity, higher transfection efficiency and uniqueness in cell targeting and cell nucleus positioning function. The cationization silk fibroin disclosed by the invention can form a cationization silk / gene compound with a gene substance through electrostatic action, and the cationization silk / gene compound is a novel biodegradable cationization silk gene transfer vector with cell targeting and a cell nucleus positioning function.

Owner:SUZHOU UNIV

Cationic silk fibroin/gene compound, and preparation method and application thereof

ActiveCN104099372AGuaranteed biodegradabilityHigh transfection efficiencyOther foreign material introduction processesVector-based foreign material introductionChemistryWater soluble

The invention discloses a cationic silk fibroin / gene compound, and a preparation method and application thereof and belongs to the technical field of polymeric biomaterials. The cationic silk fibroin / gene compound, and the preparation method and application thereof are characterized in that a cationic silk gene transmission carrier which has cell targeting and cell nucleus positioning functions and can be biodegraded is established and is obtained through the following steps: protamine sulfate is mediated by a water-soluble 2-imino thiacyclopentane hydrochloride to be in coupled with and react with the silk fibroin activated by sulfo-succunyl imino group-4-[N-maleimide methyl]-cyclohexane-1-carboxylic ester; the combination and a gene matter form the cationic silk fibroin / gene compound through electrostatic interaction. According to the invention, the cationic silk fibroin / gene compound has good biocompatibility and degradability, is controllable in surface charge density, can be effectively compressed and protect DNA, is relatively high in transfection efficiency, and has the particular cell targeting and cell nucleus positioning functions.

Owner:SUZHOU UNIV

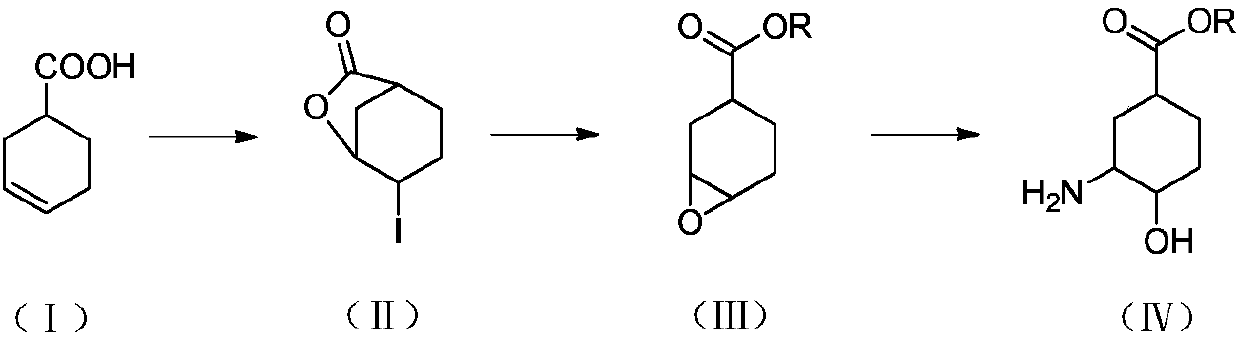

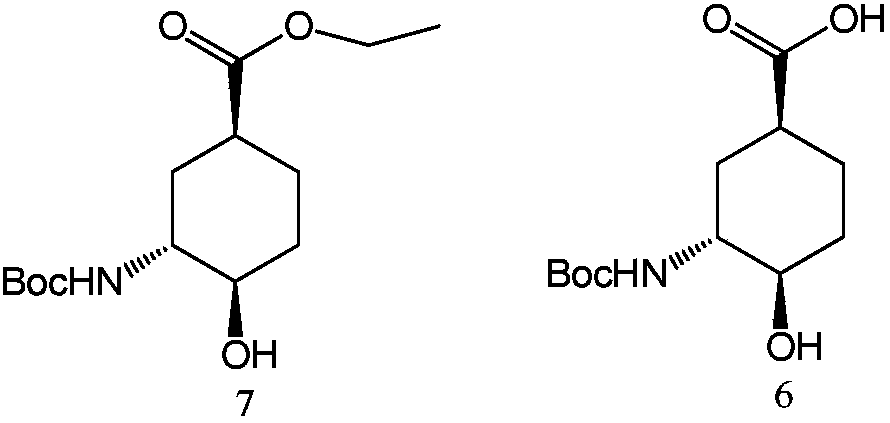

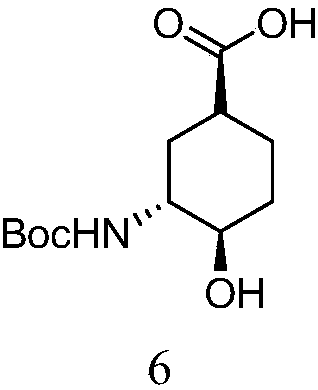

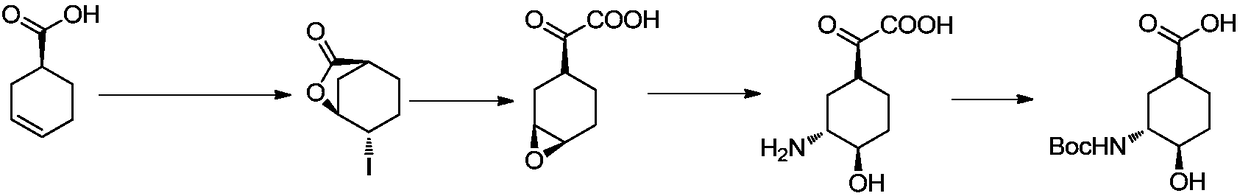

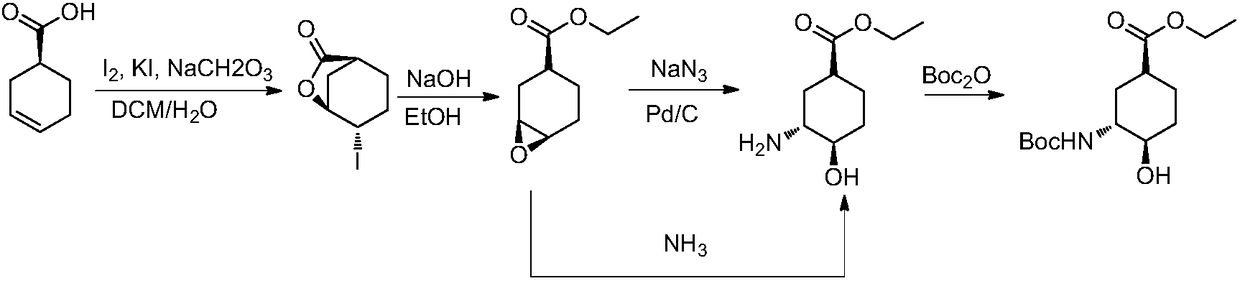

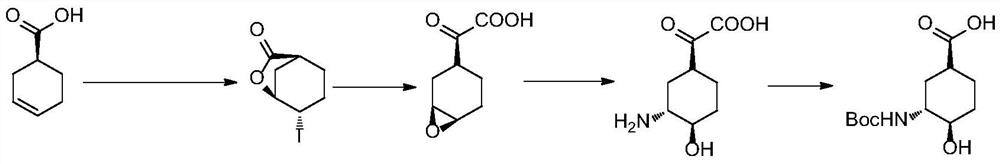

Preparation method of edoxaban intermediate

ActiveCN107721866AEfficient manufacturingReduce manufacturing costCarbamic acid derivatives preparationOrganic compound preparationTert-Butyloxycarbonyl protecting groupLithium hydroxide

Owner:ASTATECH CHENGDU BIOPHARM CORP

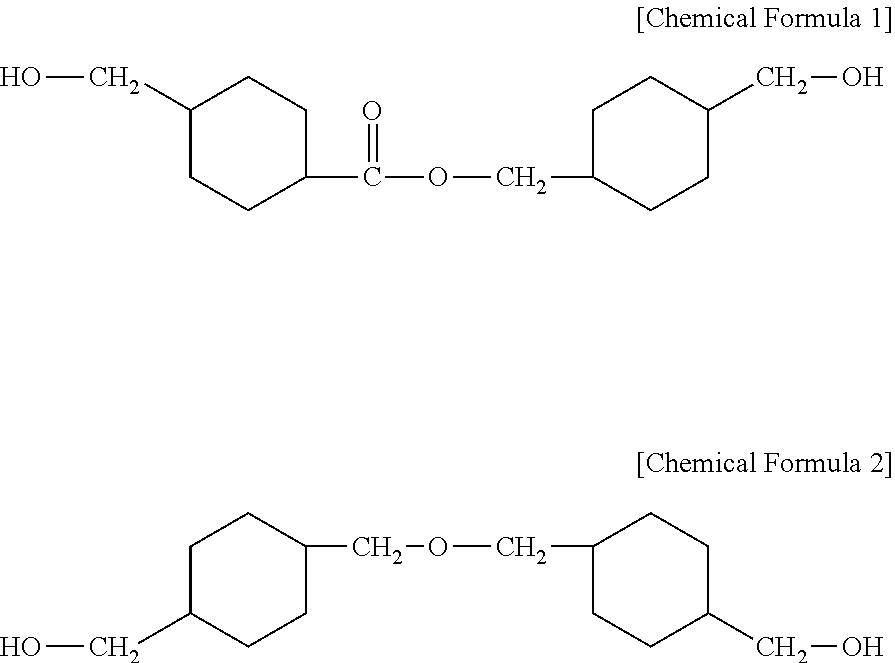

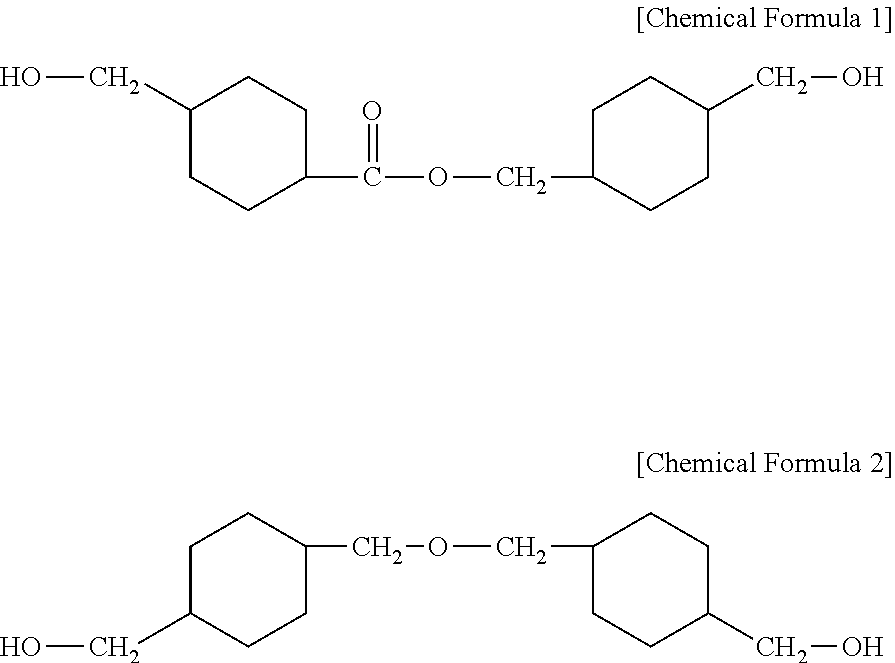

Polyester based copolymer resin and molded product comprising the same

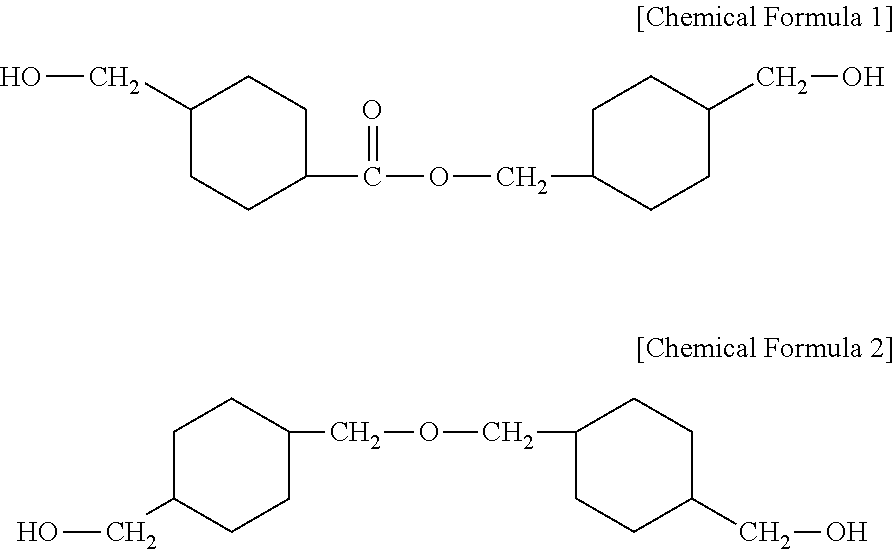

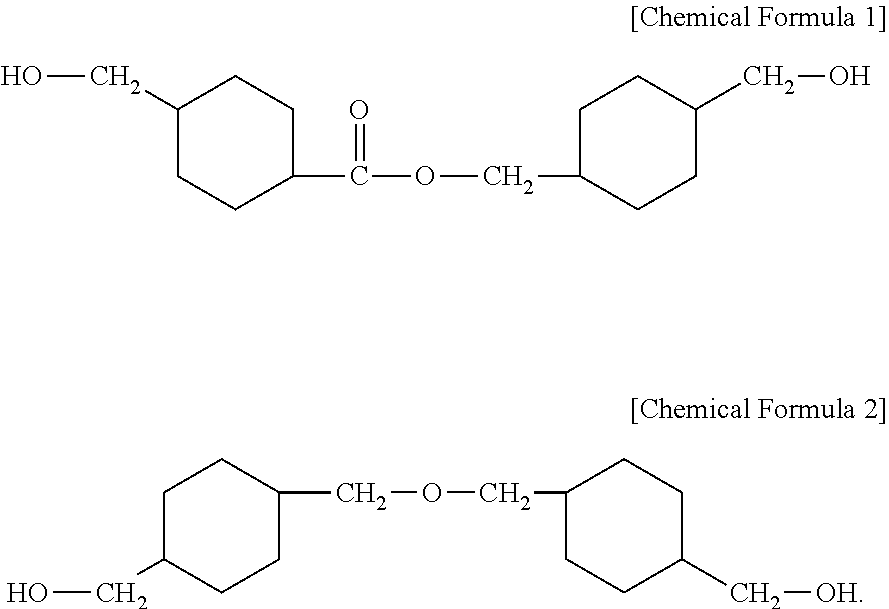

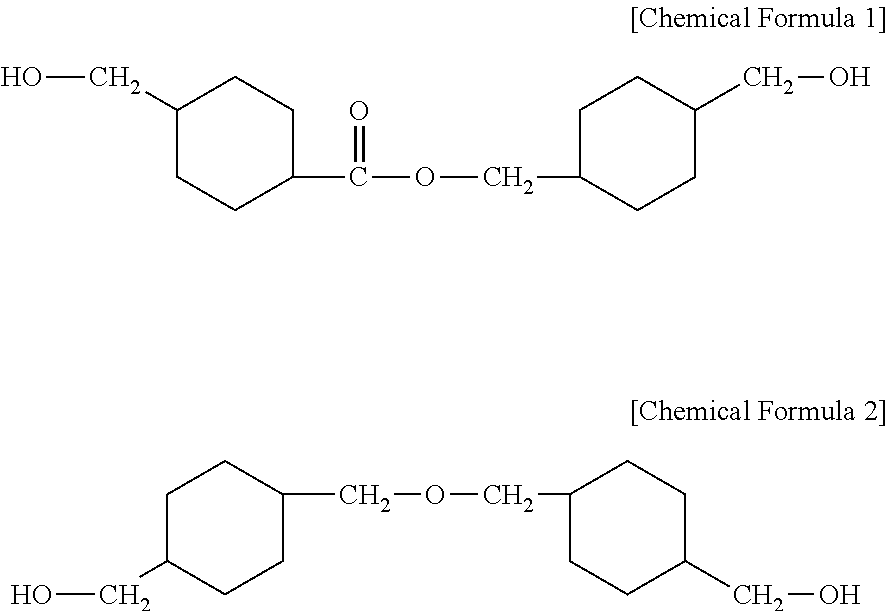

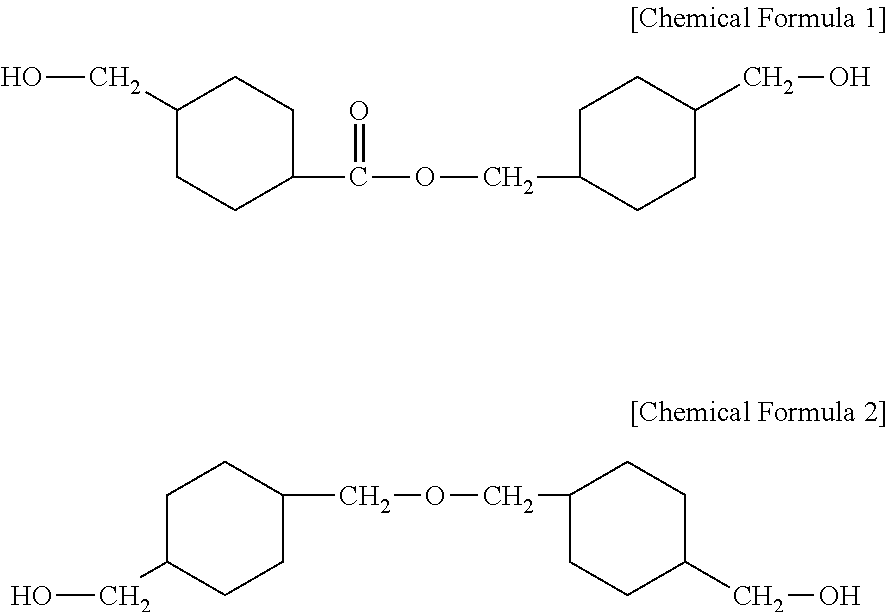

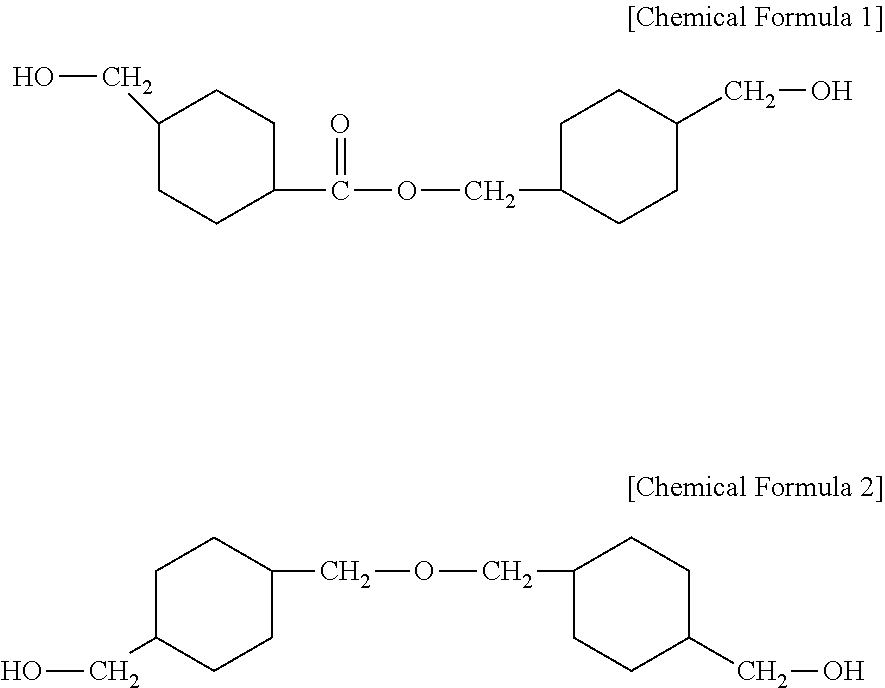

There are provided a polyester based copolymer resin capable of having an excellent shrinkage rate and being heat-shrunk at a low temperature, and a molded product comprising the same. The polyester based copolymer resin includes a dicarboxylic acid-derived residue including a residue derived from an aromatic dicarboxylic acid; and a diol-derived residue including a predetermined residue derived from 4-(hydroxymethyl)cyclohexylmethyl 4′-(hydroxymethyl)cyclohexane carboxylate and a predetermined residue derived from 4,4-(oxybis(methylene)bis)cyclohexane methanol.

Owner:SK CHEM CO LTD

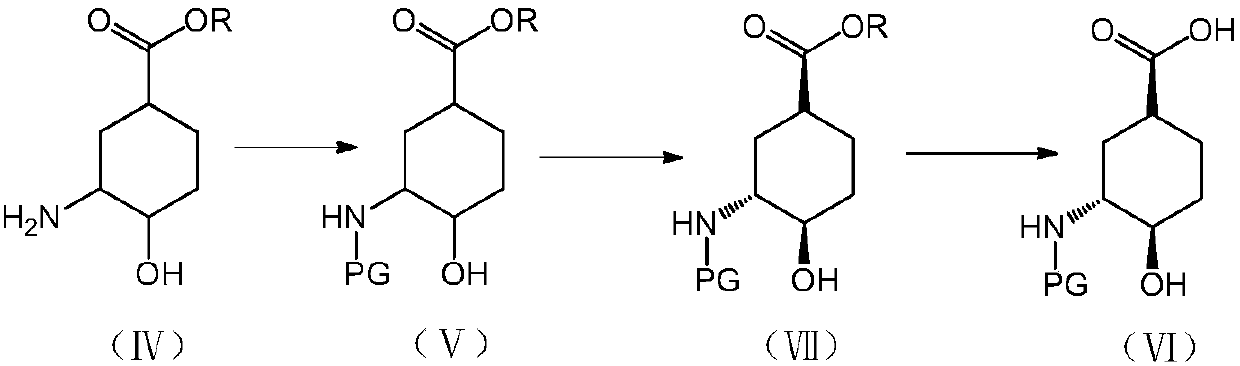

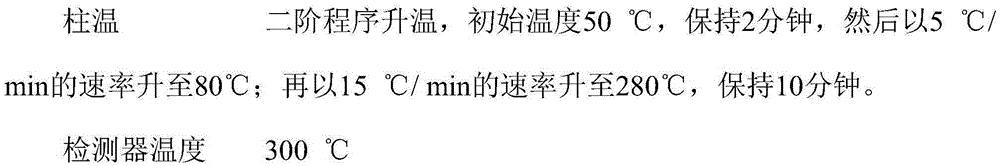

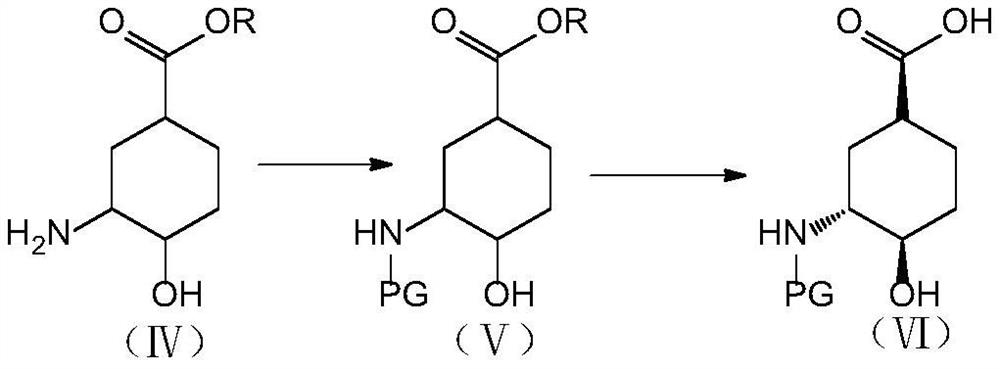

Preparation method for high-purity edoxaban intermediate

The invention discloses a preparation method for the high-purity edoxaban intermediate (1S,3R,4R)-3-tertbutyloxycarbonylamino-4-hydroxy-naphthenic acid. The preparation method comprises the followingsteps: with 3-amino-4-hydroxy-cyclohexane carboxylate as shown in a formula (IV) which is described in the invention as a raw material, subjecting the raw material to protection by an amino protectivegroup so as to obtain 3-tertbutyloxycarbonylamino-4-hydroxy-cyclohexane carboxylate as shown in a formula (V) which is described in the invention; and carrying out enzyme hydrolysis and splitting soas to obtain optically pure (1S,3R,4R)-3-tertbutyloxycarbonylamino-4-hydroxy-naphthenic acid as shown in a formula (VI) which is described in the invention. The preparation method provided by the invention has the advantages of simple operation, environmental protection, high selectivity, low cost and the like, can realize large-scale industrial production, and is convenient for industrial promotion and application.

Owner:ASTATECH CHENGDU BIOPHARM CORP

Thermo-shrinkable polyester film

ActiveUS20170232721A1Reduce contentEfficiently protect contentLayered product treatmentSynthetic resin layered productsUv absorbanceHeat resistance

This disclosure relates to a thermo-shrinkable polyester film with excellent UV absorbance and heat resistance. According to one embodiment of the invention, provided is a thermo-shrinkable polyester film comprising a first resin layer comprising polyester resin comprising residues of dicarboxylic acid components comprising aromatic dicarboxylic acid, and residues of diol components comprising 4-(hydroxymethyl)cyclohexylmethyl 4′-(hydroxymethyl)cyclohexanecarboxylate, and 4,4-(oxybis(methylene)bis)cyclohexane methanol; and a second resin layer comprising the polyester resin and a UV absorber, formed on at least one side of the first layer.

Owner:SK CHEM CO LTD

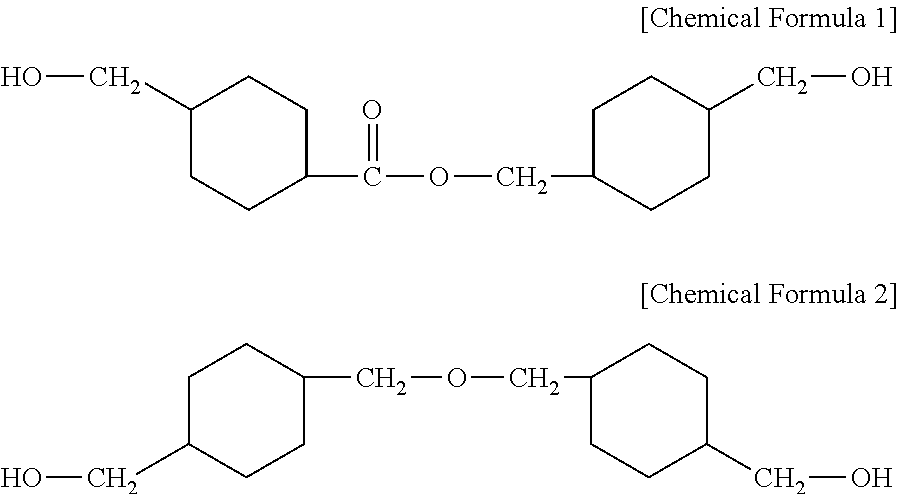

Heat shrinkable film comprising polyester based copolymer

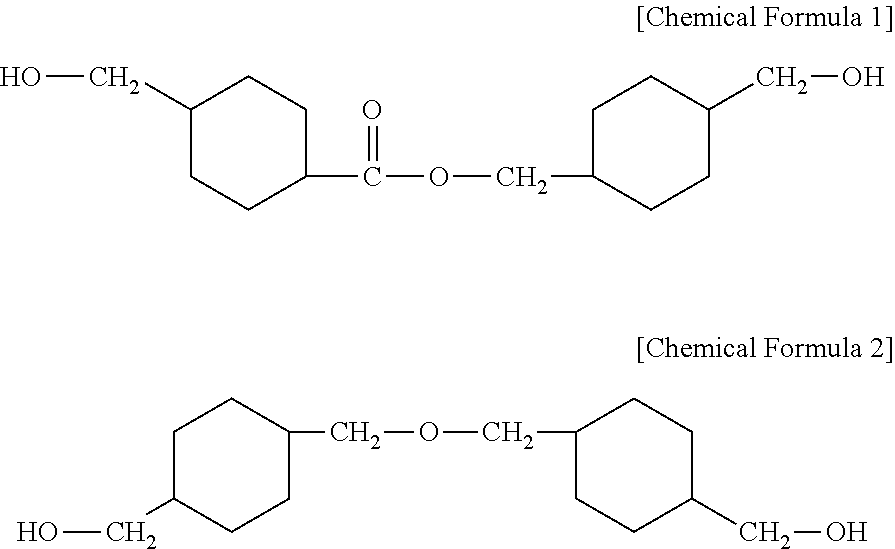

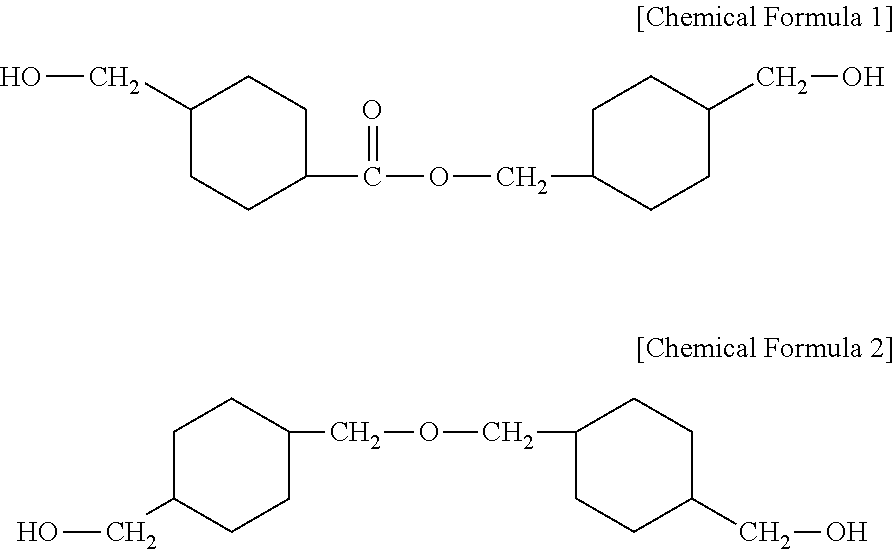

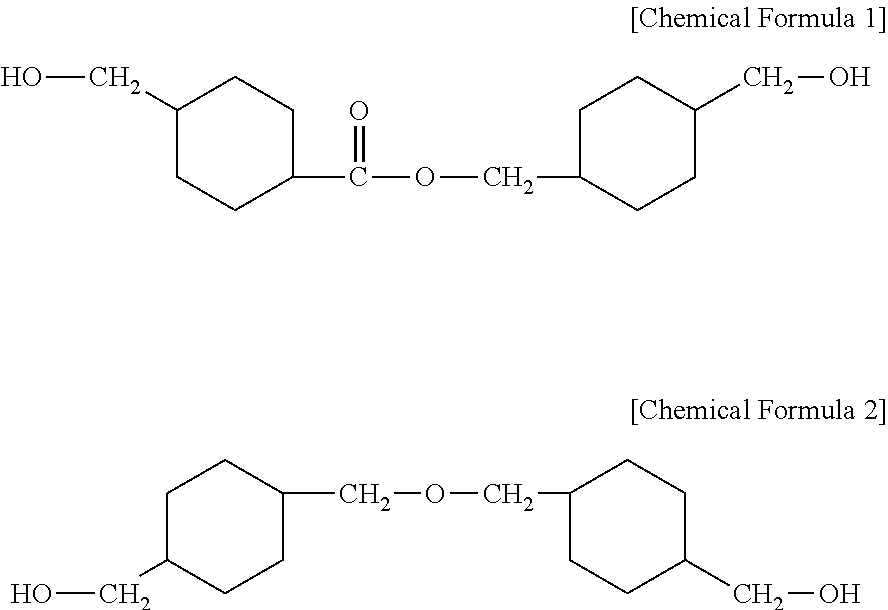

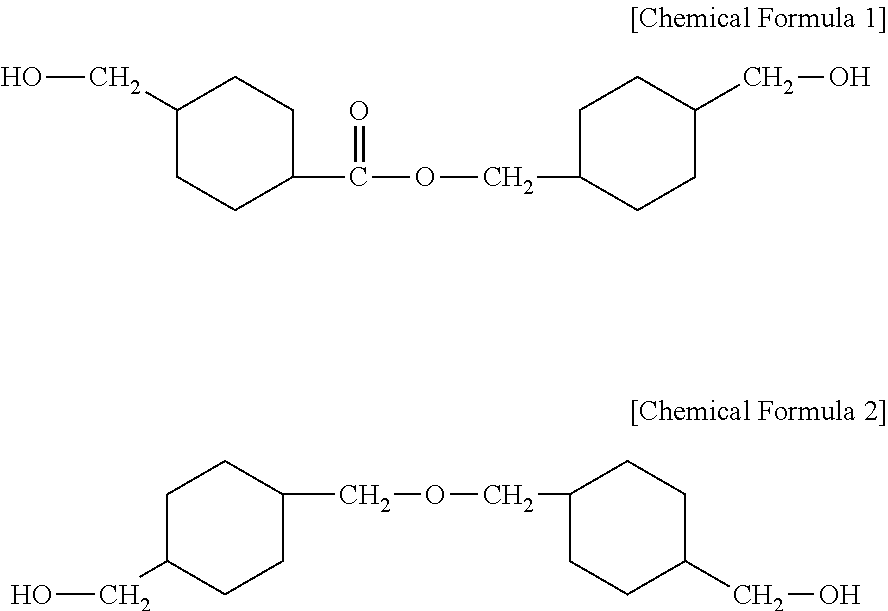

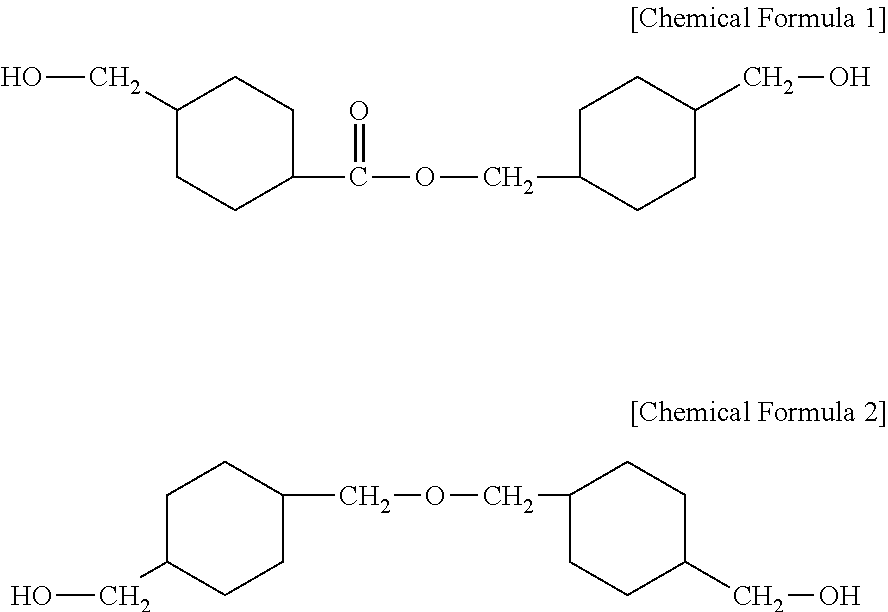

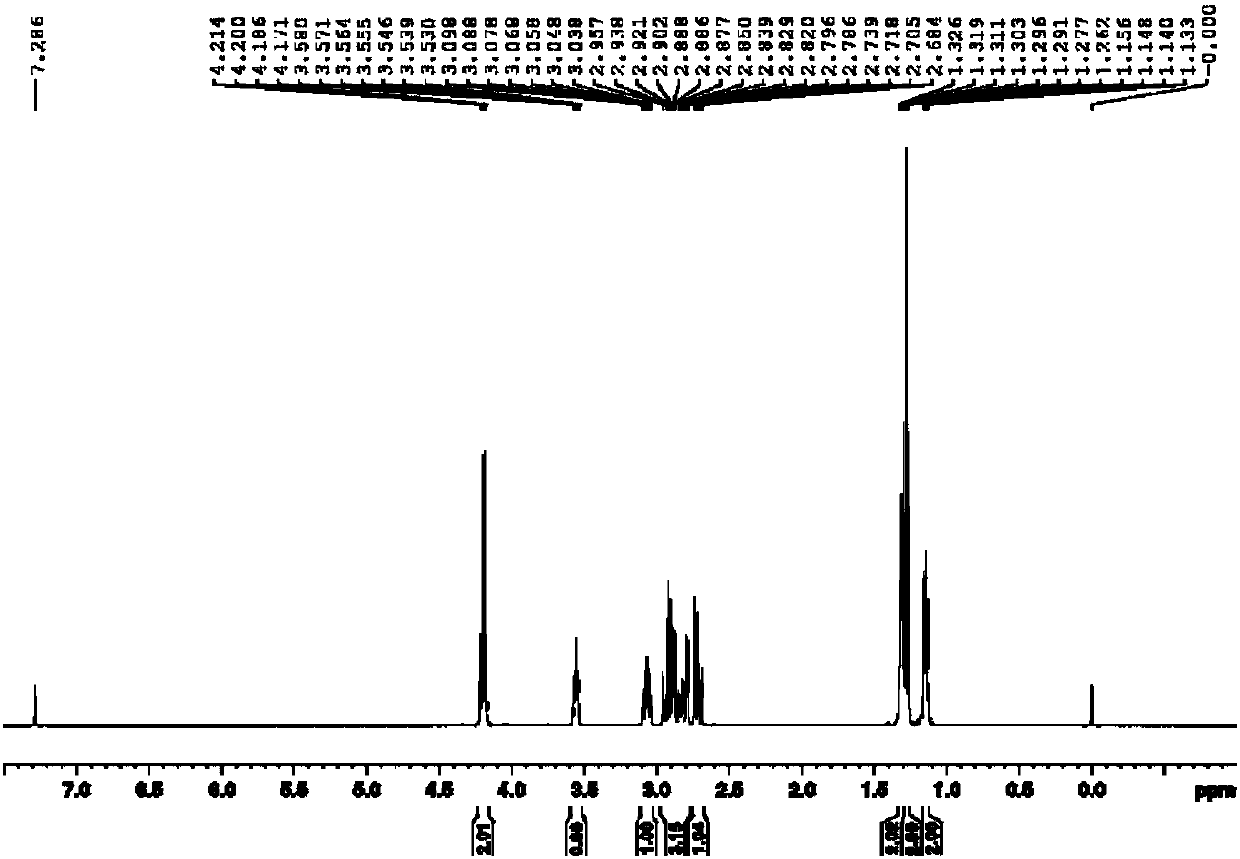

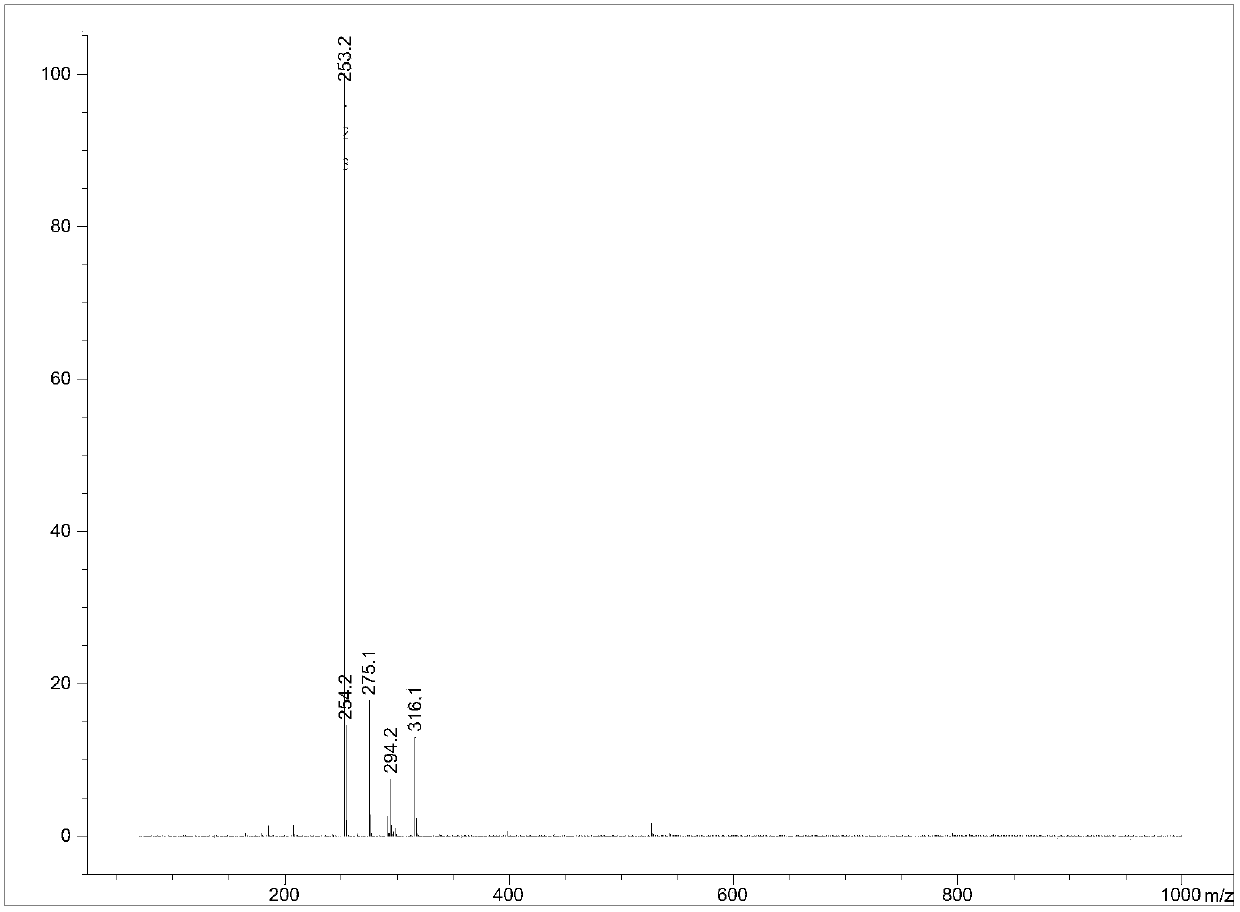

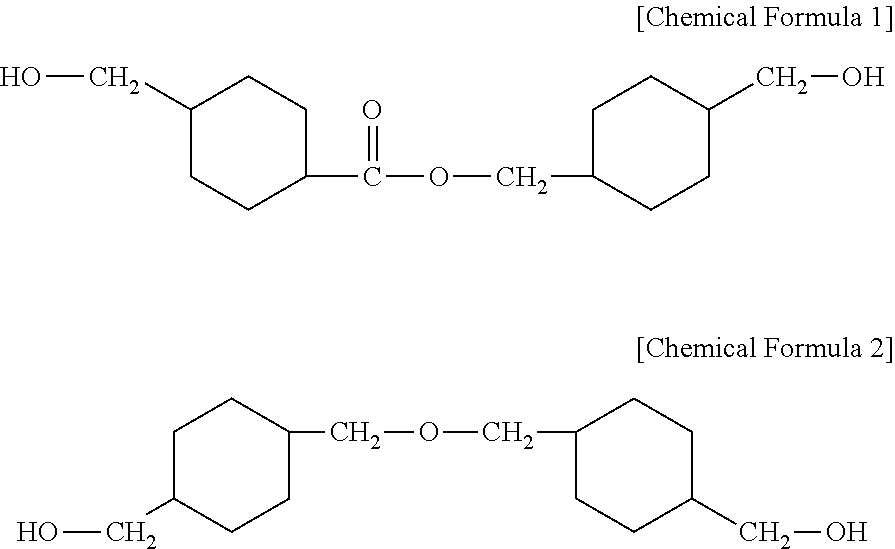

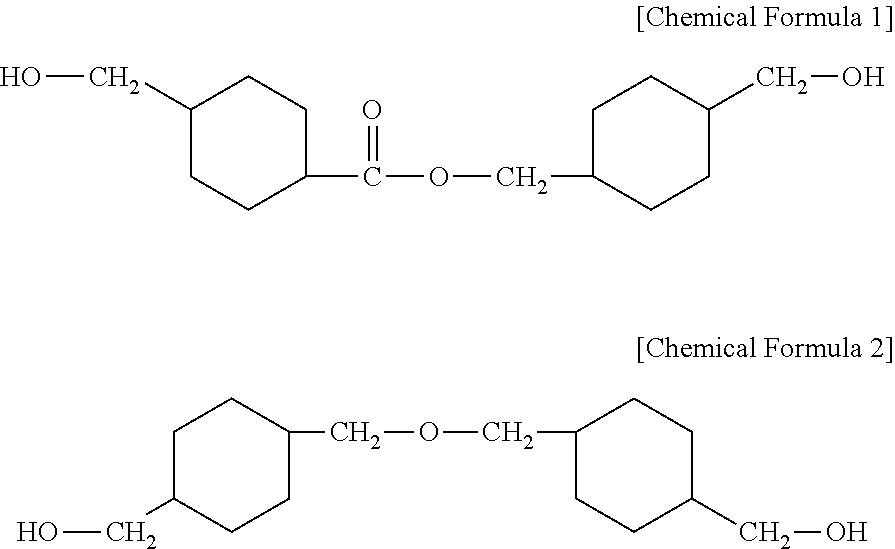

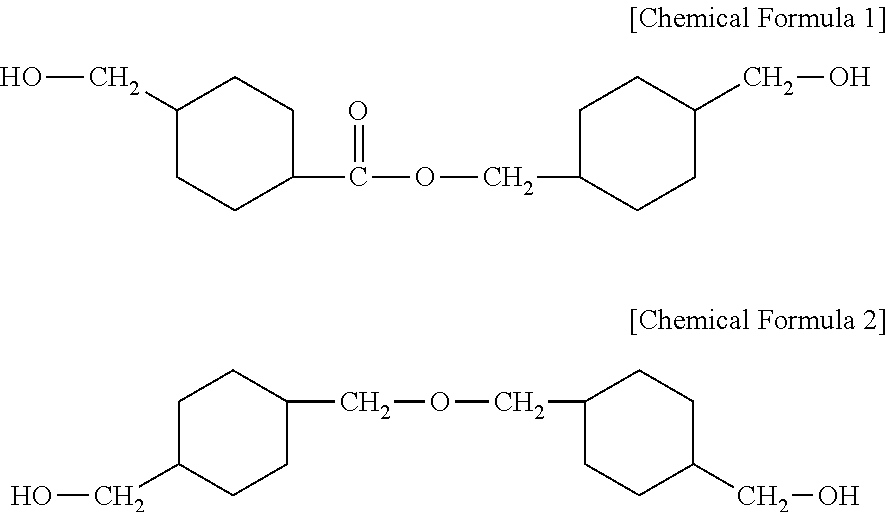

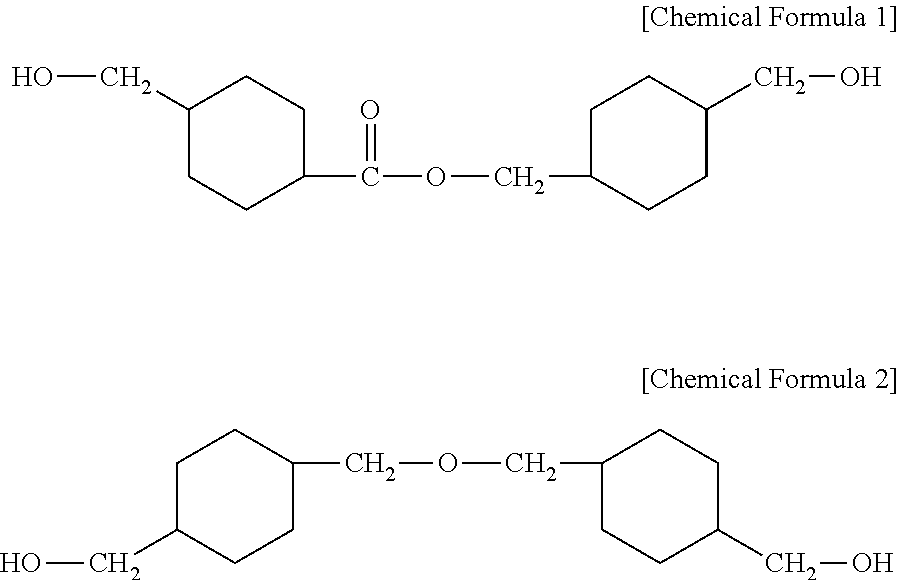

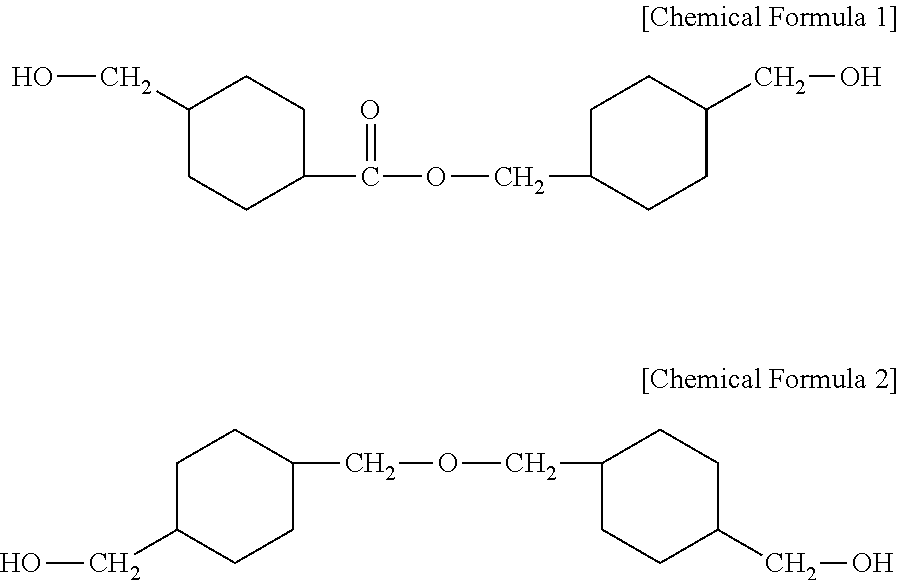

There is provided a heat shrinkable film comprising a polyester based copolymer capable of having an excellent shrinkage rate and being heat shrunk at a low temperature. The heat shrinkable film according to an exemplary embodiment of the present invention includes a polyester based copolymer, wherein the polyester based copolymer includes: a dicarboxylic acid-derived residue including a residue derived from an aromatic dicarboxylic acid; and a diol-derived residue including a residue derived from 4-(hydroxymethyl)cyclohexylmethyl 4′-(hydroxymethyl)cyclohexane carboxylate represented by the following Chemical Formula 1 and a residue derived from 4,4-(oxybis(methylene)bis) cyclohexane methanol represented by the following Chemical Formula 2.

Owner:SK CHEM CO LTD

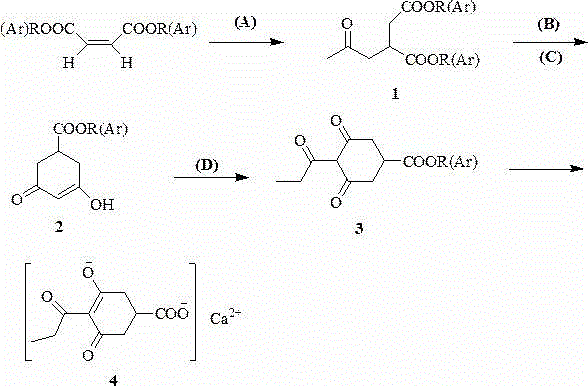

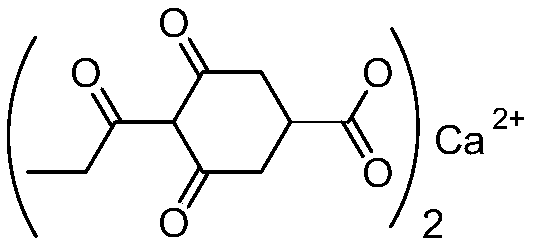

Production method of 4-cyclopropyl (hydroxy) methylene -3,5-diketone ethyl cyclohexane carboxylate and recycling method thereof

ActiveCN109776328AReduce outputEasy to recycleOrganic compound preparationCarboxylic acid esters preparationDiketoneOrganic solvent

The invention relates to the field of the organic synthesis, and discloses a production method of 4-cyclopropyl (hydroxy) methylene -3,5-diketone ethyl cyclohexane carboxylate and a recycling method thereof. The recycling method comprises the following steps: (1) enabling a liquid mixture containing the compound as shown in formula (1) to contact with metal ion in a first organic solvent under a complexation condition, and performing solid-liquid separation to obtain solid phase and liquid phase, wherein the metal is one or multiple metal elements in the ninth line, the tenth line, the eleventh line and the twelfth line of an element periodic table, and the pH value of the liquid mixture is greater than 6; (2) under a ligand dissociation condition, enabling the solid phase to contact withprotonic acid in the second organic solvent to obtain the organic phase and aqueous phase containing the compound as shown in formula (1), optionally separating the compound as shown in formula (1) from the organic phase. Through the method disclosed by the invention, the compound as shown in formula (1) with high purity can be recycled from the waste liquid in a comparatively high yield.

Owner:NUTRICHEM LAB CO LTD

Polyester based copolymer resin and molded product comprising the same

Owner:SK CHEM CO LTD

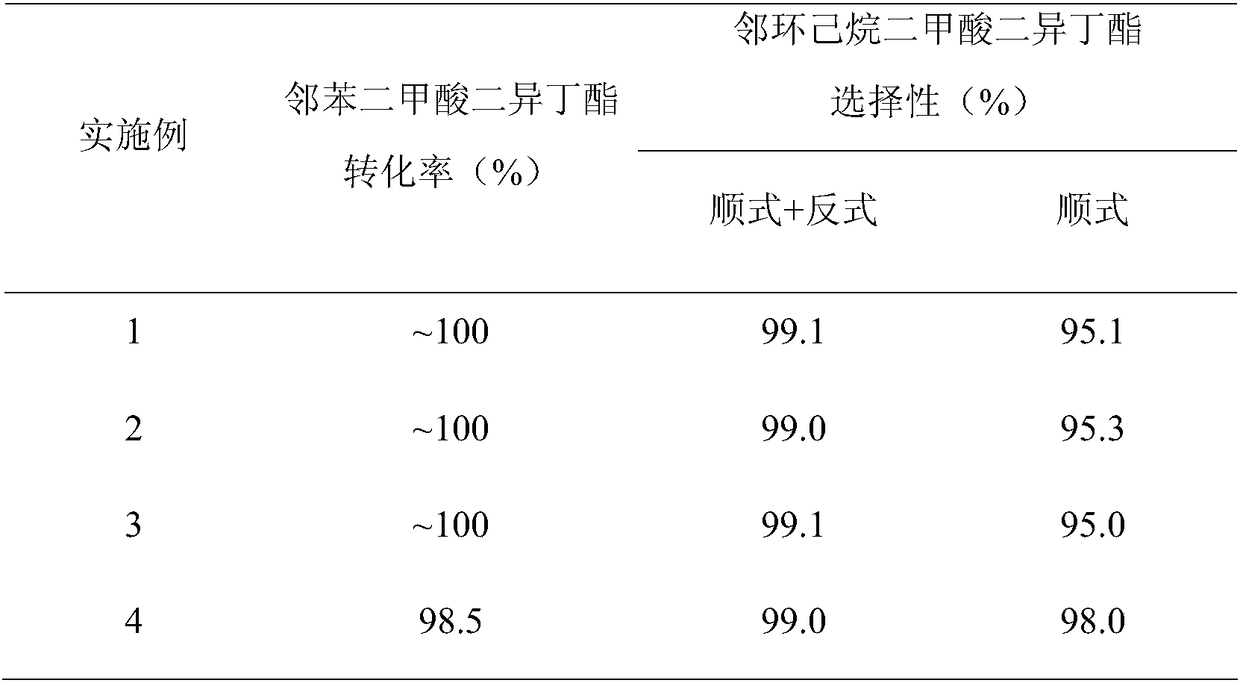

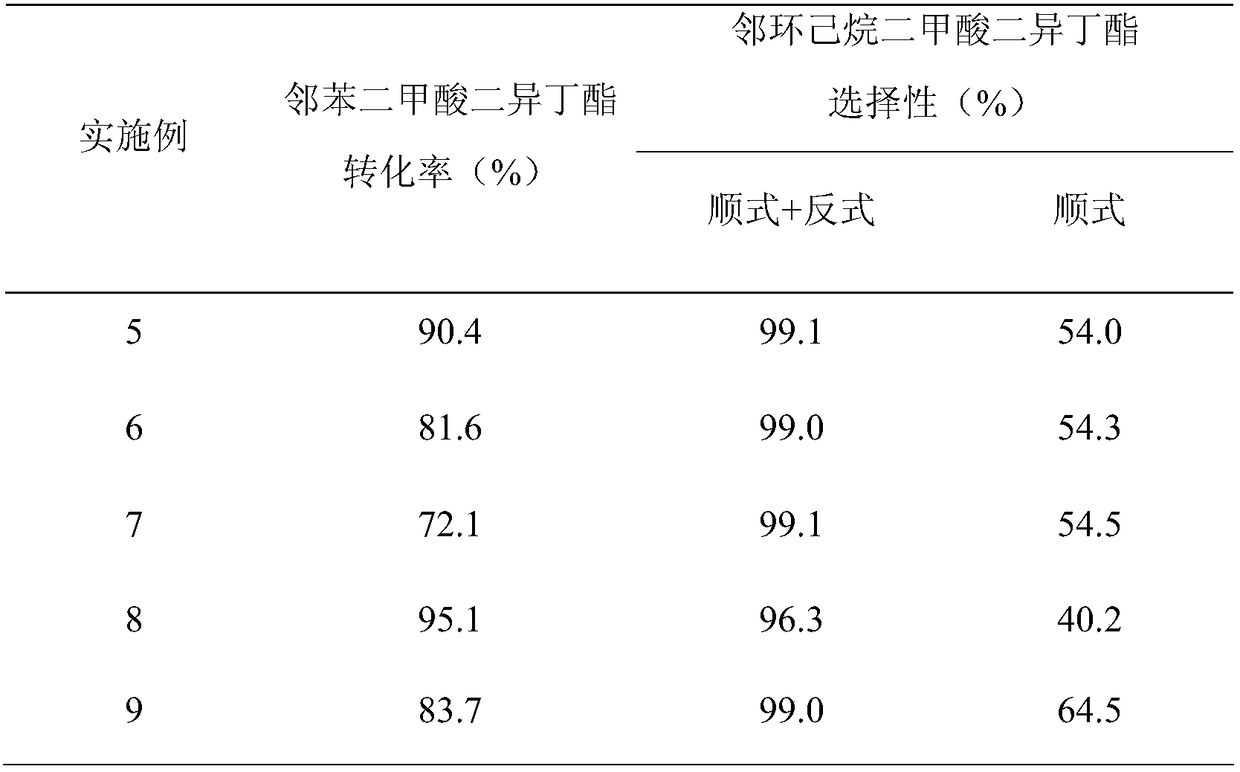

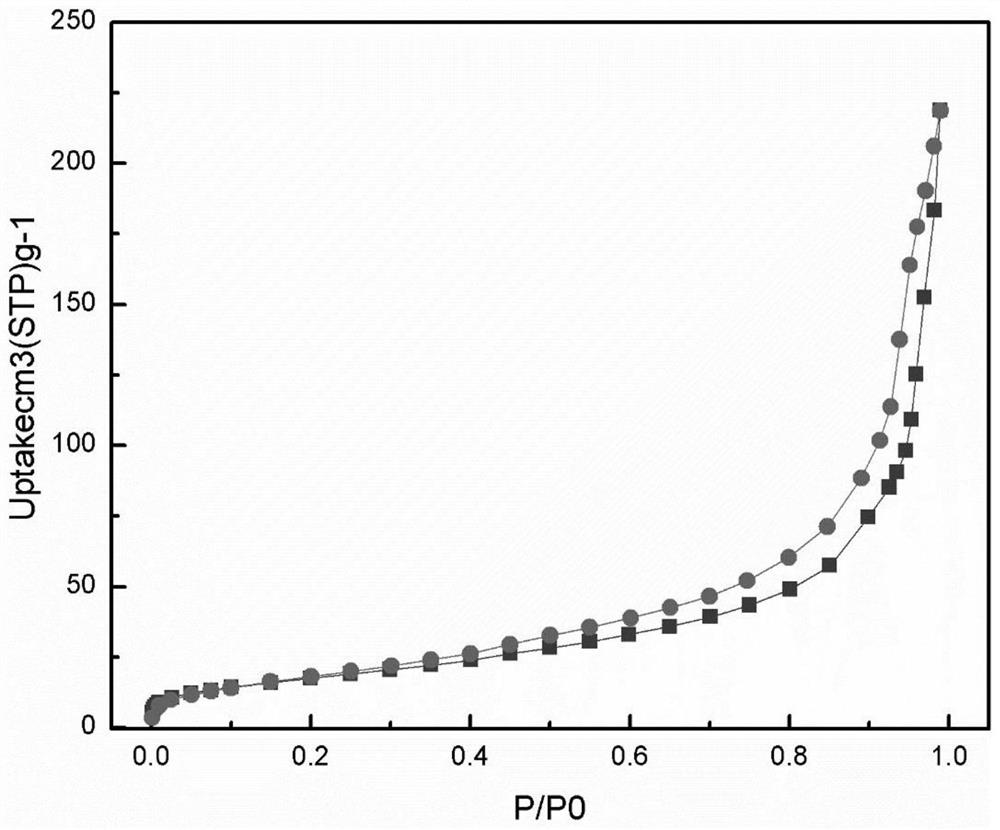

Application of catalyst, and preparation method for disubstituted cyclohexane carboxylate with adjustable cis-trans ratio

ActiveCN108160079AOrganic compound preparationOrganic chemistry methodsHydrogenation reactionActive component

The invention relates to application of a catalyst, and a preparation method for disubstituted cyclohexane carboxylate with an adjustable cis-trans ratio. The catalyst is used for adjusting the cis-trans ratio of disubstituted cyclohexane carboxylate produced by a hydrogenation reaction of aromatic carboxylate. The preparation method comprises a step of, with aromatic carboxylate as a raw material, carrying out a hydrogenation reaction in the presence of the catalyst so as to produce disubstituted cyclohexane carboxylate, wherein the produced disubstituted cyclohexane carboxylate comprises cis-disubstituted cyclohexane carboxylate and trans-disubstituted cyclohexane carboxylate, and the active component of the catalyst is one or more selected from a group consisting of Ru, Pd and Ni. Withthe preparation method, cis-disubstituted cyclohexane carboxylate and trans-disubstituted cyclohexane carboxylate in different ratios can be prepared; when the active component of the catalyst is Ni,cis-disubstituted cyclohexane carboxylate accounts for 40 to 65%; when the active component of the catalyst is Ru, cis-disubstituted cyclohexane carboxylate accounts for 75 to 90%; and when the activecomponent of the catalyst is Pd, cis-disubstituted cyclohexane carboxylate accounts for 95 to 98%.

Owner:SHANGHAI HUAYI ENERGY CHEM

Heat shrinkable film comprising polyester based copolymer

A heat shrinkable film comprising a polyester based copolymer is provided. The heat shrinkable film according to an exemplary embodiment of the present invention includes a polyester based copolymer, wherein the polyester based copolymer includes: a dicarboxylic acid-derived residue including a residue derived from an aromatic dicarboxylic acid; and a diol-derived residue including a residue derived from 4-(hydroxymethyl)cyclohexylmethyl 4′-(hydroxymethyl)cyclohexane carboxylate represented by the following Chemical Formula 1 and a residue derived from 4,4-(oxybis(methylene)bis) cyclohexane methanol represented by the following Chemical Formula 2;

Owner:SK CHEM CO LTD

Heat shrinkable film comprising polyester based copolymer

There is provided a heat shrinkable film comprising a polyester based copolymer capable of having an excellent shrinkage rate and being heat shrunk at a low temperature. The heat shrinkable film according to an exemplary embodiment of the present invention includes a polyester based copolymer, wherein the polyester based copolymer includes: a dicarboxylic acid-derived residue including a residue derived from an aromatic dicarboxylic acid; and a diol-derived residue including a residue derived from 4-(hydroxymethyl)cyclohexylmethyl 4′-(hydroxymethyl)cyclohexane carboxylate represented by the following Chemical Formula 1 and a residue derived from 4,4-(oxybis(methylene)bis) cyclohexane methanol represented by the following ChemicalFormula 2.

Owner:SK CHEM CO LTD

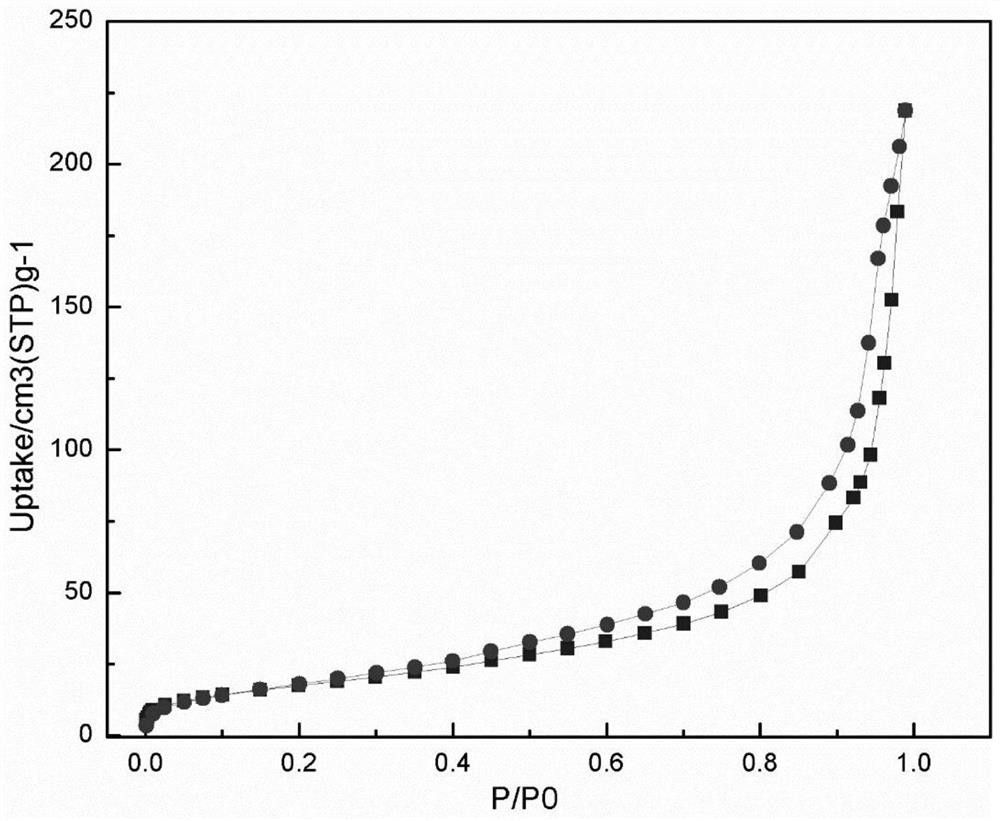

A kind of preparation method of cyclohexane carboxylate

ActiveCN106565472BUniform pore sizeSingle structureOrganic compound preparationCarboxylic acid esters preparationPlasticizerCyclohexanecarboxylic acid

Owner:WANHUA CHEM GRP CO LTD

Preparation method of prohexadione calcium

InactiveCN104478707AIncrease fat solubilityReduced fat solubilityOrganic compound preparationCarboxylic acid esters preparationChromatographic separationOrganic base

Owner:JIANGXI AGRICULTURAL UNIVERSITY

Heat shrinkable film composition comprising polyethyleneterephtalate resin and polyester based copolymer, and heat shrinkable film

There is provided a composition for forming a heat shrinkable film capable of providing a heat shrinkable film capable of having an excellent shrinkage rate and being heat-shrunk at a low temperature. The composition for forming a heat shrinkable film includes a polyethylene terephthalate (PET) resin having an inherent viscosity of 0.50 to 1.2 dl / g, and a polyester based copolymer including a dicarboxylic acid-derived residue including a residue derived from an aromatic dicarboxylic acid and a diol-derived residue including a residue derived from 4-(hydroxymethyl)cyclohexylmethyl 4′-(hydroxymethyl)cyclohexane carboxylate represented by the following Chemical Formula 1 and a residue derived from 4,4-(oxybis(methylene)bis) cyclohexane methanol represented by the following Chemical Formula 2.

Owner:SK CHEM CO LTD

Preparation method of prohexadione calcium

ActiveCN109680016AHigh selectivityHigh yieldChemical recyclingFermentationOrganic solventCarboxylic acid

The invention discloses a preparation method of prohexadione calcium. The preparation method comprises the following steps: preparing a calcium acetate aqueous solution with mass percentage concentration of 20-30%, adding 3,5-dioxo-4-propionyl ethyl cyclohexane carboxylate into the calcium acetate aqueous solution, wherein a mass ratio of the aqueous solution to the 3,5-dioxo-4-propionyl ethyl cyclohexane carboxylate is (10 to 20) : 1; adding a lipase catalyst which accounts for 0.5-2% of the total mass, reacting for 2-10 hours at a temperature of 30-80 DEG C under stirring speed of 250-800 revolutions per minute, filtering and recycling the lipase catalyst, and cooling to separate out 3,5-dioxo-4-propionyl ethyl cyclohexane carboxylate, wherein the lipase catalyst is Novozyme 435, lipozyme RMIM or Lipozyme TLIM. The method does not use an organic solvent, is environmentally friendly, is high in yield and is high in purity.

Owner:浙江大鹏药业股份有限公司

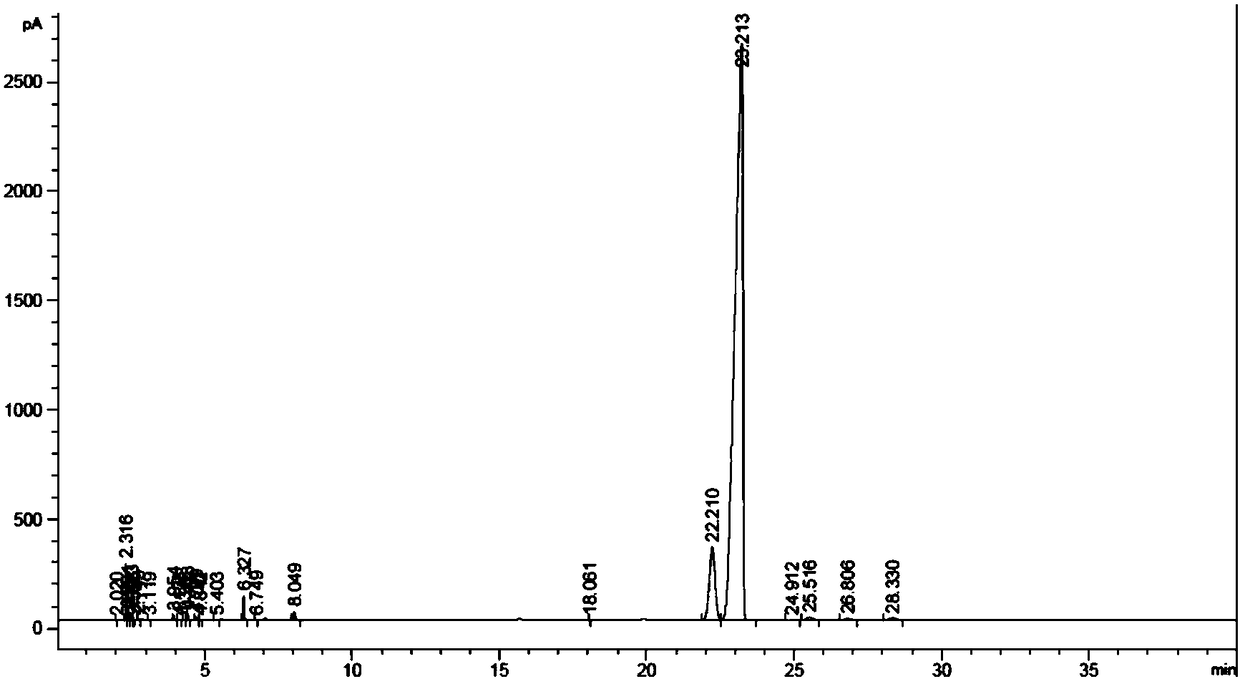

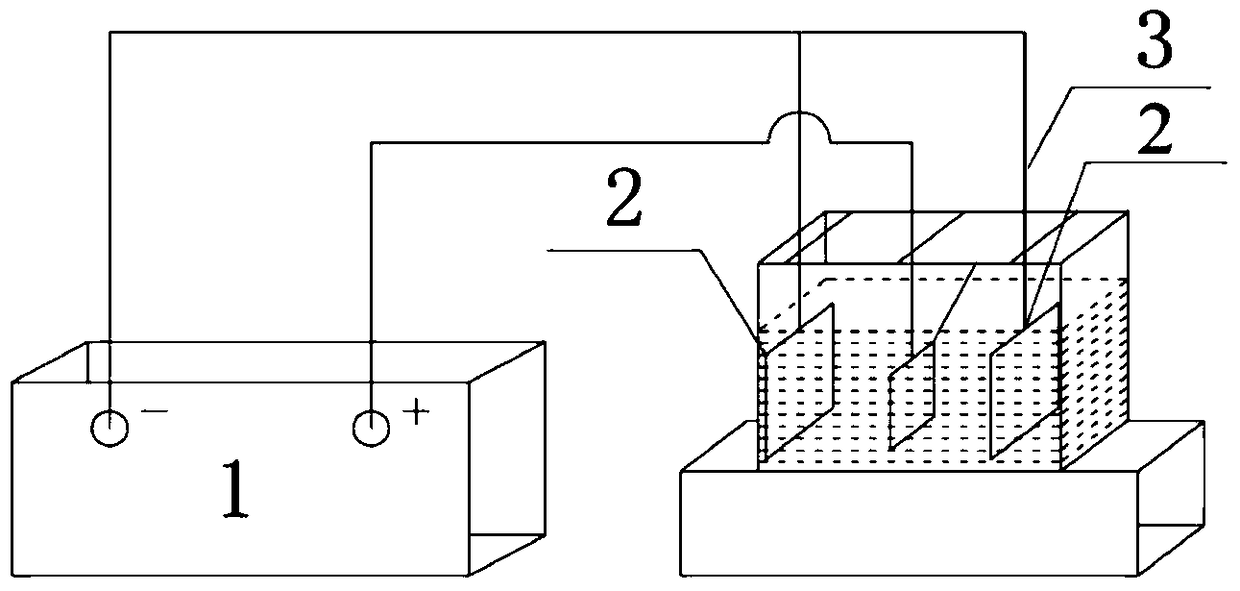

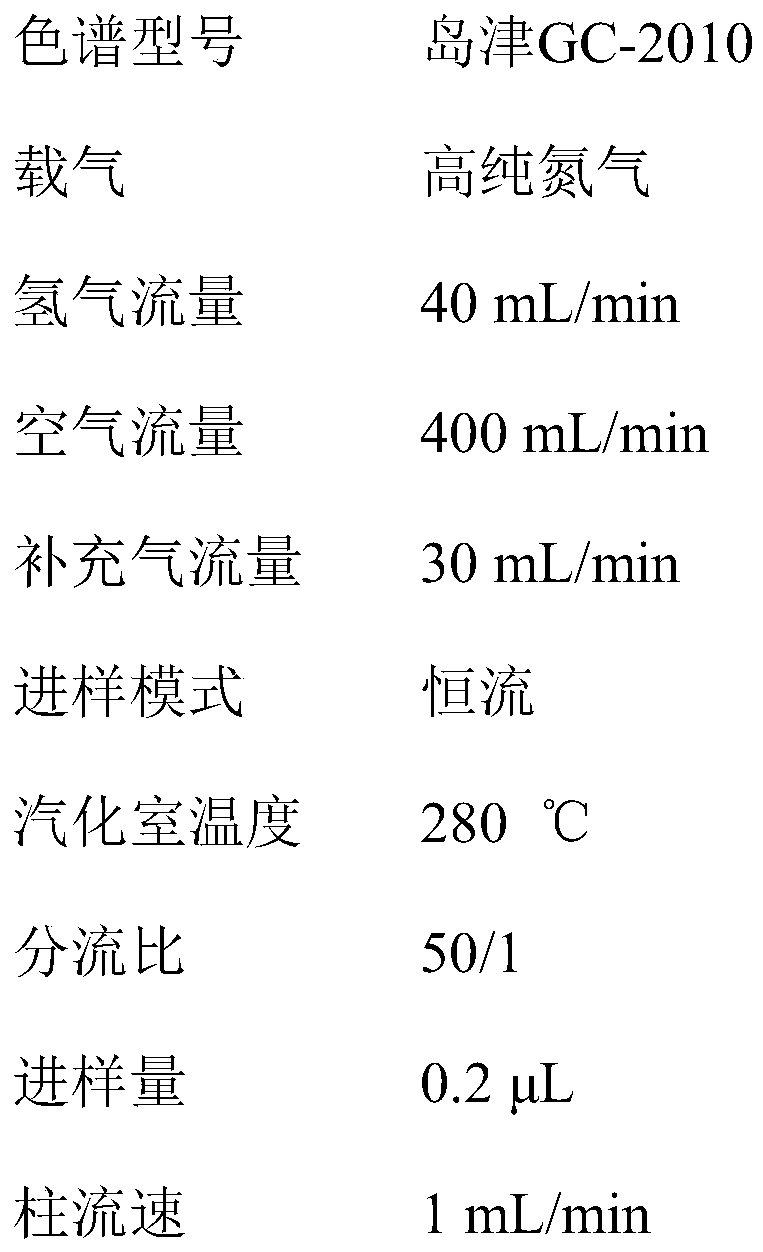

Nickel-based halloysite nanotube hydrogenation catalyst and preparation and application thereof

ActiveCN112916013AHigh activityGood choiceOrganic compound preparationCarboxylic acid esters preparationPtru catalystHydrogenation catalysis

The invention belongs to the field of cyclohexane carboxylate preparation, and particularly relates to a nickel-based halloysite nanotube hydrogenation catalyst and preparation and application thereof. According to the nickel-based halloysite nanotube hydrogenation catalyst, a halloysite nanotube serves as a carrier, an active component is loaded on the halloysite nanotube in an in-situ growth mode, and the active component is nickel or a combination of nickel and one or more of the following metal elements: Cu, W, Ce, Al, Pr, Y and B. The nickel-based halloysite nanotube hydrogenation catalyst provided by the invention has high activity and good selectivity, is suitable for hydrogenation production with naphthalene orthophthalic acid esters as raw materials, has a great cost advantage of the catalyst per unit product, and can also realize a very high raw material conversion rate after being repeatedly used for many times. Besides, according to the production process provided by the invention, the orthophthalic acid ester raw material in the final finished product is reduced to the ppm level, the refining cost of the product is greatly reduced, and the production process has a remarkable market cost advantage.

Owner:河南天宁新材料科技有限公司 +1

A kind of preparation method of trinexapac-ethyl and its intermediate

ActiveCN105085270BImprove qualityGood process reaction selectivityOrganic compound preparationCarboxylic acid esters preparationAcetoacetatesFormate

The invention discloses a preparation method of trinexapac-ethyl and an intermediate thereof. The method comprises the following steps: under the action of an alkali, reacting acetoacetic ester (I) with diethyl maleate to obtain an intermediate (II), continuing reaction under the action of an acid to obtain diethyl 2-acetonyl-1,4-succinate; cyclizing the diethyl 2-acetonyl-1,4-succinate in the presence of an alkali, and acidifying to obtain ethyl 3,5-cyclohexyldione-formate; esterifying the ethyl 3,5-cyclohexyldione-formate and cyclopropyl formyl chloride in the presence of an acid-binding agent to obtain ethyl 4-cyclopropylformacyl-3,5-dione cyclohexane-carboxylate; and carrying out reaction on the end product under the actions of an organic alkali and a catalyst to obtain the trinexapac-ethyl. The technique has the advantages of favorable reaction selectivity, high yield and fewer byproducts, and is beneficial to obtaining the high-quality trinexapac-ethyl product. The method does not have high requirements for equipment, and avoids high-temperature high-pressure reaction. The method has the advantages of simple technique and mild reaction conditions, and is suitable for industrialization.

Owner:MAX RUDONG CHEM

Cyclohexanecarboxylic acid ester preparation method

ActiveCN106565472AUniform pore sizeSingle structureOrganic compound preparationCarboxylic acid esters preparationPlasticizerCyclohexanecarboxylic acid

The present invention relates to a cyclohexanecarboxylic acid ester preparation method, wherein the compound is obtained by carrying out selective hydrogenation on a phthalic acid derivative, and the used hydrogenation catalyst is a Ni, Co, Mn and Al2O3-SiO2 composite nano-tube array film hydrogenation catalyst, wherein the catalyst has high activity and high selectivity in the cyclohexanecarboxylic acid ester preparation reaction through the selective hydrogenation of the phthalic acid derivative, and the hydrogenation product is a class of the wide-application plasticizers.

Owner:WANHUA CHEM GRP CO LTD

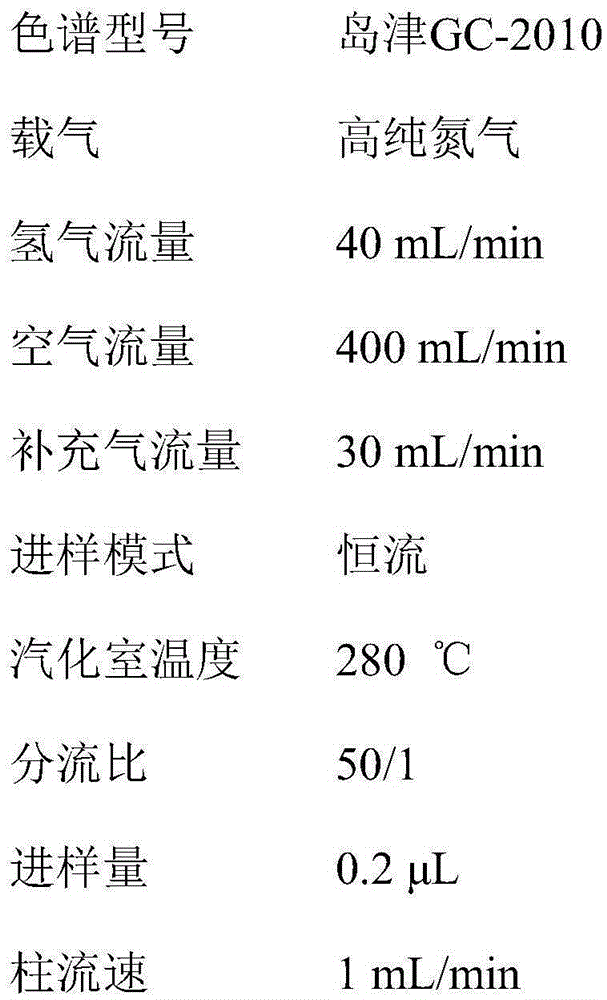

The preparation method of high-purity edoxaban intermediate

The invention discloses a preparation method of a high-purity edoxaban intermediate (1S, 3R, 4R)-3-tert-butoxycarbonylamino-4-hydroxy-cyclohexanecarboxylic acid. With the 3-amino-4-hydroxyl-cyclohexane carboxylate shown in formula (Ⅳ) as raw material, obtain 3-tert-butoxycarbonylamino-4-hydroxyl-ring as shown in formula (Ⅴ) after the protection of amino protecting group Hexane carboxylate, and enzymatic hydrolysis and resolution to obtain optically pure (1S, 3R, 4R)-3-tert-butoxycarbonylamino-4-hydroxy-cyclohexanecarboxylic acid represented by formula (VI). The method of the invention has the advantages of simple operation, environmental protection, high selectivity, low cost, etc., can realize large-scale industrial production, and is convenient for industrial popularization and application.

Owner:ASTATECH CHENGDU BIOPHARM CORP

Catalyst for production of cyclohexylcarboxylate by phenylcarboxylate hydrogenation and its preparation method and use

ActiveCN102658146BHigh activityHigh selectivityOrganic compound preparationCarboxylic acid esters preparationActive componentHigh activity

The invention discloses a catalyst for production of cyclohexylcarboxylate by phenylcarboxylate hydrogenation and its preparation method and use. The catalyst comprises 5 to 50wt% of an active component Ni, 0.1 to 25wt% of at least one auxiliary agent and the balance a carrier. The catalyst has the advantages of low price and very high activity and selectivity.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

A cationic silk fibroin/gene complex, preparation method and application thereof

ActiveCN104099372BAvoid cross-linking reactionsLow costOther foreign material introduction processesVector-based foreign material introductionGene deliveryCarboxylic acid

The invention discloses a cationic silk fibroin / gene complex, a preparation method and an application thereof, and belongs to the technical field of biomedical polymer materials. The present invention constructs a novel biodegradable cationic silk fibroin gene transfer carrier with cell targeting and cell nucleus localization functions, which is mediated by water-soluble 2-iminothiolane hydrochloride protamine sulfate Produced by coupling silk fibroin activated with sulfosuccinimidyl-4-[N-maleimidomethyl]-cyclohexane-1-carboxylate and forms cations with genetic material by electrostatic interaction Fibroin / gene complex has good biocompatibility and degradability, controllable surface charge density, ability to effectively compress and protect DNA, high transfection efficiency, unique cell targeting and nuclear localization functions.

Owner:SUZHOU UNIV

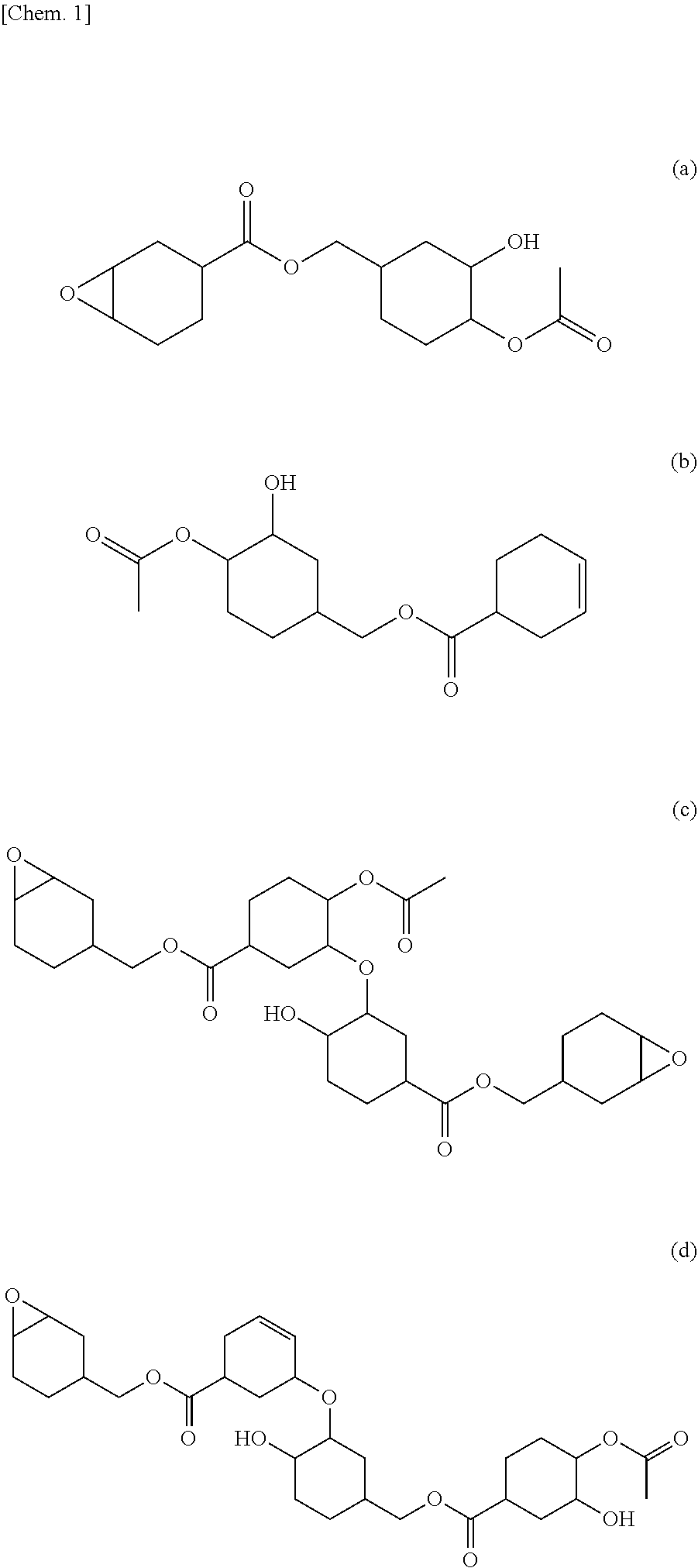

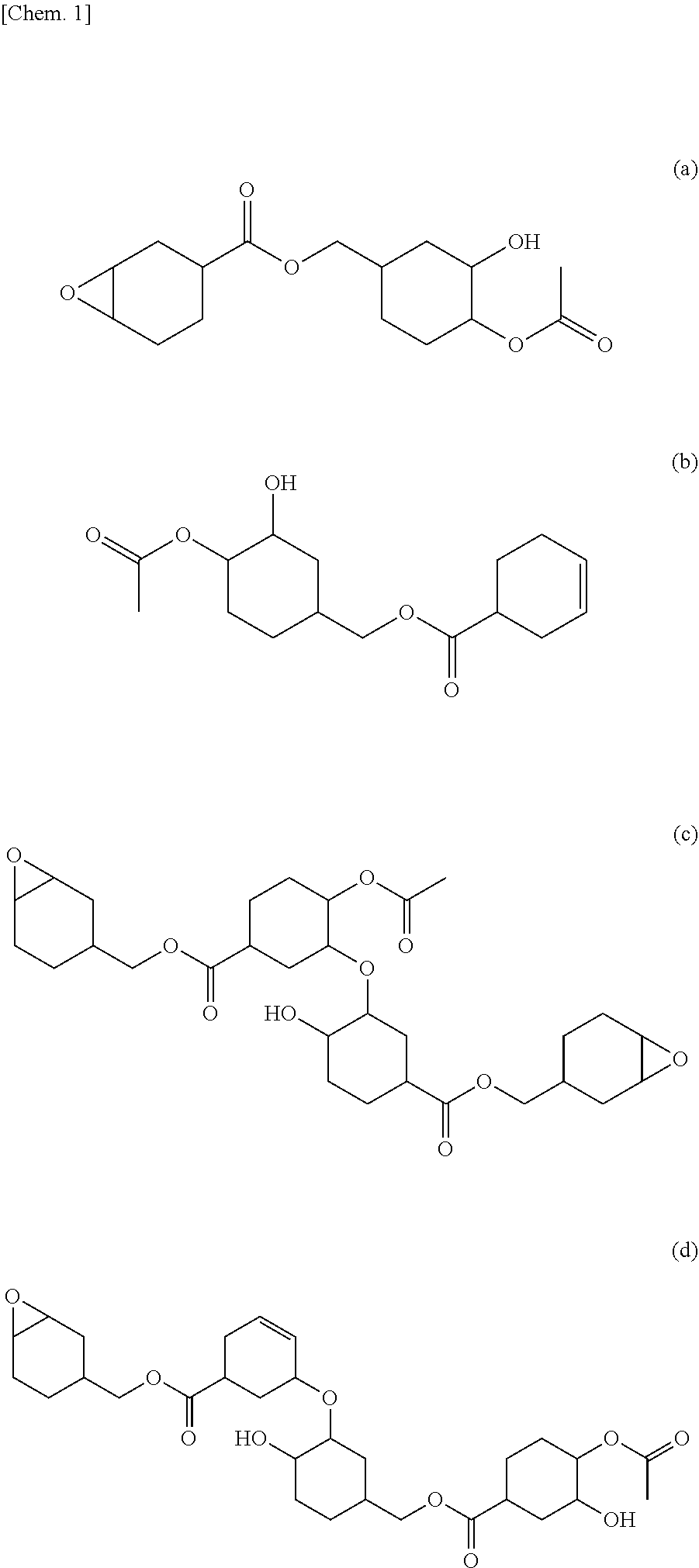

Alicyclic epoxy compound product

ActiveUS20210189058A1High purityReduce contentEpoxy resin adhesivesEpoxy resin coatingsPolymer scienceMeth-

Provided is an alicyclic epoxy compound product used in applications for forming a cured product excellent in heat resistance and transparency.The alicyclic epoxy compound product according to an embodiment of the present invention includes 3,4-epoxycyclohexylmethyl(3,4-epoxy)cyclohexanecarboxylate, a purity of which is of not less than 98.5 wt. %, and each content of a compound represented by Formula (a) below, a compound represented by Formula (b) below, a compound represented by Formula (c) below, and a compound represented by Formula (d) below is not greater than 0.5 wt. %.

Owner:DAICEL CHEM IND LTD

Adhesive agent composition for multilayer semiconductor

InactiveUS10047257B2Less progressEasy to cutSemiconductor/solid-state device detailsSolid-state devicesCationic polymerizationSemiconductor chip

Provided is an adhesive composition for multilayer semiconductors. The adhesive composition gives, when applied and dried by heating, an adhesive layer that has approximately no adhesiveness at a temperature lower than 50° C., but, when heated at such a temperature as to less cause damage to semiconductor chips, offers adhesiveness and is rapidly cured thereafter. This adhesive composition for multilayer semiconductors includes a polymerizable compound (A), at least one of a cationic-polymerization initiator (B1) and an anionic-polymerization initiator (B2), and a solvent (C). The polymerizable compound (A) contains 80% by weight or more of an epoxide having a softening point or melting point of 50° C. or higher. The cationic-polymerization initiator (B1) gives a composition having a thermal curing time of 3.5 minutes or longer at 130° C., where the composition contains 1 part by weight of the cationic-polymerization initiator (B1) and 100 parts by weight of 3,4-epoxycyclohexylmethyl (3,4-epoxy)cyclohexanecarboxylate. The anionic-polymerization initiator (B2) gives a composition having a thermal curing time of 3.5 minutes or longer at 130° C., where the composition contains 1 part by weight of the anionic-polymerization initiator (B2) and 100 parts by weight of bisphenol-A diglycidyl ether.

Owner:DAICEL CHEM IND LTD

Process for producing expandable styrene polymer compositions

InactiveUS8889748B2High mechanical strengthPositive influenceHeat proofingPolymer sciencePolymer composition

Owner:BASF AG

UV woodware paint for carbonized material, and manufacturing method thereof

InactiveCN109337526ALarge amount of applicationImprove permeabilityAntifouling/underwater paintsPaints with biocidesTetramethylammonium bromideAcrylic resin

The invention discloses a UV woodware paint for carbonized material, and a manufacturing method thereof. The UV woodware paint is prepared by taking epoxy acrylic resin, polyurethane acrylic resin, tetraethylammonium bromide, cobalt cyclohexane carboxylate, chitosan powder, adequate amount of absolute ethyl alcohol, titanium dioxide powder, fatty alcohol-polyoxyethylene ether, GST modified epoxy carbon-sticking glue, functional components extracted from cornu gorais, closed isocyanate, and defoaming agent as raw material and taking deionized water as the medium to sufficiently react at 70-85 DEG C, whereien the preparation process of the function components comprises infiltrating, dicing, braising, purifying and concentrating. The UV woodware paint disclosed by the invention has the technical effects of being dedicated to the carbonized wood surface, cured by ultraviolet, incapable of damaging the wood, high in adhesive force, high in wear resistance, high in permeation, and self-hydrophobic.

Owner:JIANGSU HIMONIA TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com