Preparation method of prohexadione calcium

A technology of prohexadione calcium and calcium acetate, applied in chemical recovery, fermentation and other directions, can solve the problems of low total yield and cumbersome process, and achieve the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

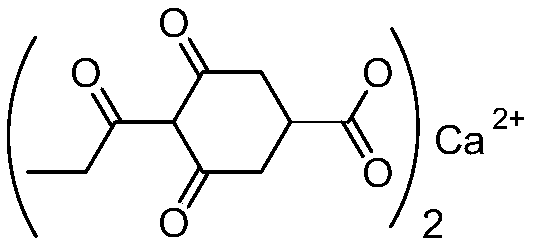

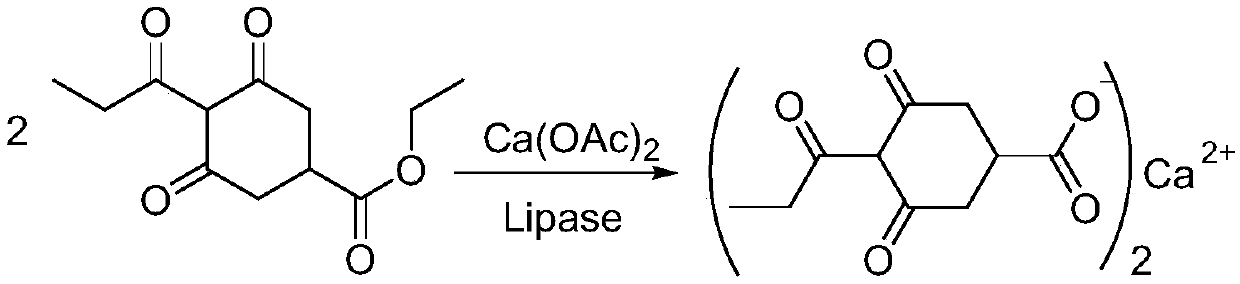

Image

Examples

preparation example Construction

[0023] A preparation method of prohexadione calcium is as follows:

[0024] Prepare a calcium acetate aqueous solution with a concentration of 20-30% by mass, add 3,5-dioxo-4-propionylcyclohexanecarboxylate ethyl ester to the calcium acetate aqueous solution, wherein the aqueous solution is mixed with 3,5-dioxo - The mass ratio of ethyl 4-propionylcyclohexanecarboxylate is 10-20:1, add 0.5-2% lipase catalyst in total mass, and react at 30-80°C and 250-800 r / min stirring speed After 2-10 hours, the lipase catalyst was recovered by filtration, and the white solid calcium 3,5-dioxo-4-propionylcyclohexanecarboxylate was precipitated by cooling down.

Embodiment 1

[0026] Add 20 grams of calcium acetate to 80 grams of water to form a 20% solution, add the calcium acetate aqueous solution to a 250ml three-necked flask with stirring, add 10 grams of 3,5-dioxo-4-propionylcyclohexanecarboxylate Ethyl acid, 0.55 g Novozyme 435, react at 30°C, 250-r / min stirring speed for 10 hours, filter and recover the lipase catalyst Novozyme 435, cool down to precipitate white 3,5-dioxo-4-propionylcyclohexane Calcium carboxylate, dried, weighed to obtain 9.5 g, yield 98.7%, HPLC content 98.7%, IR (cm -1 ): 2889.1, 1645.2, 1561.1, 1381.3.

Embodiment 2

[0028] Add 30 grams of calcium acetate to 70 grams of water to form a 30% solution, add the calcium acetate aqueous solution to a 250 ml three-necked flask with stirring, add 20 grams of 3,5-dioxo-4-propionylcyclohexanecarboxylate Acetate ethyl ester, 2.4 g lipozyme RMIM, react at 80 ° C, 800 r / min stirring speed for 2 hours, filter and recover the lipase catalyst lipozyme RMIM, cool down and separate out white 3,5-dioxo-4-propionylcyclohexane Calcium carboxylate was dried and weighed to obtain 18.8 g, the yield was 97.6%, and the HPLC content was 98.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com