Nickel-based halloysite nanotube hydrogenation catalyst and preparation and application thereof

A technology of halloysite nanotubes and hydrogenation catalysts, applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, preparation of organic compounds, etc. volume, non-renewable and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

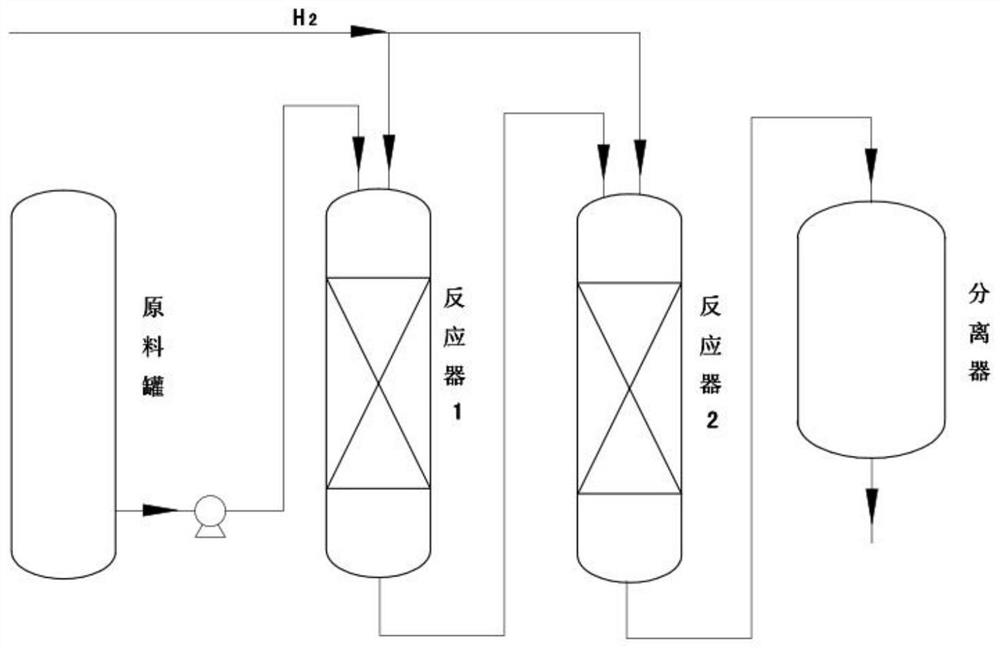

Embodiment 1

[0044] Adopt the in-situ growth preparation method, dissolve 132.5g of nickel nitrate in 400ml of deionized water as solution A, and put 120g of halloysite powder in 500ml of absolute ethanol, stir and ultrasonically disperse for 5h to prepare uniformly dispersed suspension B . Mix solution A and suspension B, stir evenly to obtain solution C, control the temperature of solution C to 85°C, add urea to slowly hydrolyze it in the solution system, adjust the pH value of the mixed solution to 12, stir for 16 hours, and the stirring speed is 100r / min, during which the active components grow slowly and controllably on the halloysite nanotubes in situ, and the resulting green precipitate undergoes solid-liquid separation. The separated solid was washed five times with deionized water and ethanol in turn to obtain a nickel-based catalyst precursor. Place the precursor in a vacuum drying oven at 110°C for 10 hours, then place it in a muffle furnace, and then heat it up to 500°C for 6...

Embodiment 2

[0046] Dissolve 128.2g of nickel nitrate, 2.6g of cerium nitrate, and 3.8g of praseodymium carbonate in 400ml of deionized water to obtain solution A, and put 138g of halloysite powder in 500ml of absolute ethanol, stir and ultrasonically disperse for 5 hours to prepare a uniformly dispersed Suspension B. Mix solution A and suspension B, stir evenly, control the temperature of the solution at 85°C, add urea to slowly hydrolyze it in the solution system, adjust the pH value of the mixed solution to 12, stir for 16 hours, and the stirring speed is 100r / min. The active components grow slowly and controllably on the halloysite nanotubes in situ, and the resulting green precipitate undergoes solid-liquid separation. The separated solid was washed alternately with deionized water and ethanol five times each to obtain a nickel-based catalyst precursor. Place the precursor in a vacuum drying oven at 110°C for 10 hours, then place it in a muffle furnace, and then heat it up to 500°C f...

Embodiment 3

[0048] Dissolve 138.5g of nickel nitrate and 5.5g of cerium carbonate in 400ml of deionized water to form solution A, and put 126.1g of halloysite powder in 500ml of absolute ethanol, stir and ultrasonically disperse for 5h, and prepare uniformly dispersed suspension B . Mix solution A and suspension B, stir evenly, slowly (80-100ml / h) add ammonia water to adjust the pH value of the mixed solution to 12, stir for 16h, and separate the solid-liquid of the obtained green precipitate. The separated solid was washed five times with deionized water and ethanol alternately to obtain a nickel-based catalyst precursor. Place the precursor in a vacuum drying oven at 110°C for 10 hours, then place it in a muffle furnace, and then heat it up to 500°C for 6 hours in a nitrogen atmosphere at a rate of 10°C / min to obtain a nickel-based halloysite nanotube hydrogenation catalyst. .

PUM

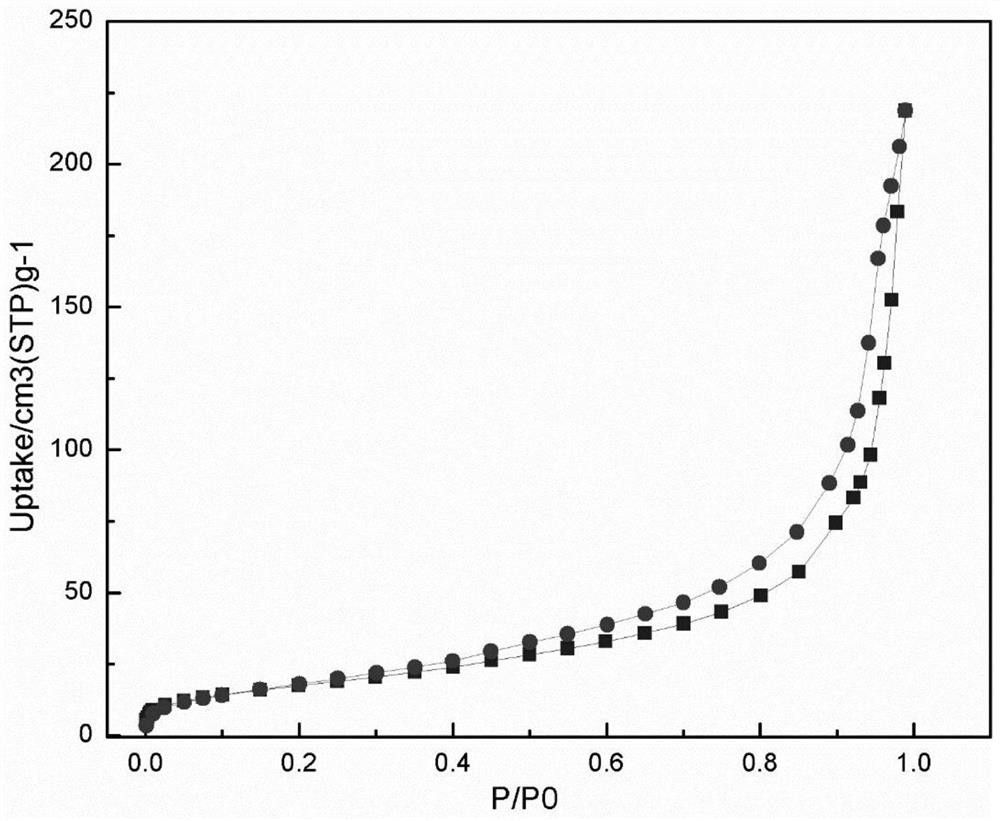

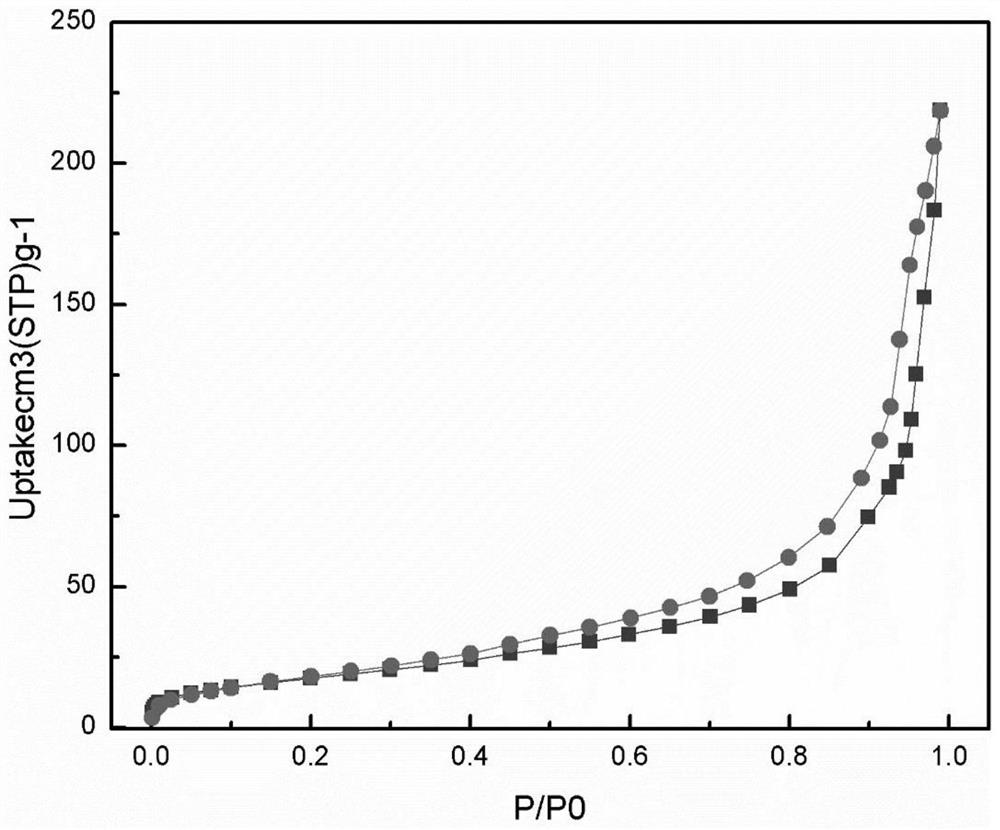

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com