A method for comprehensive recovery and utilization of lithium containing mixed salts in a polyphenylene sulfide production process

A production process, polyphenylene sulfide technology, applied in lithium halide, alkali metal chloride, organic chemistry, etc., can solve the problem of low product purity and yield, cumbersome recovery process, and the inability to realize comprehensive recycling of by-product slurry and other issues, to achieve the effect of easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

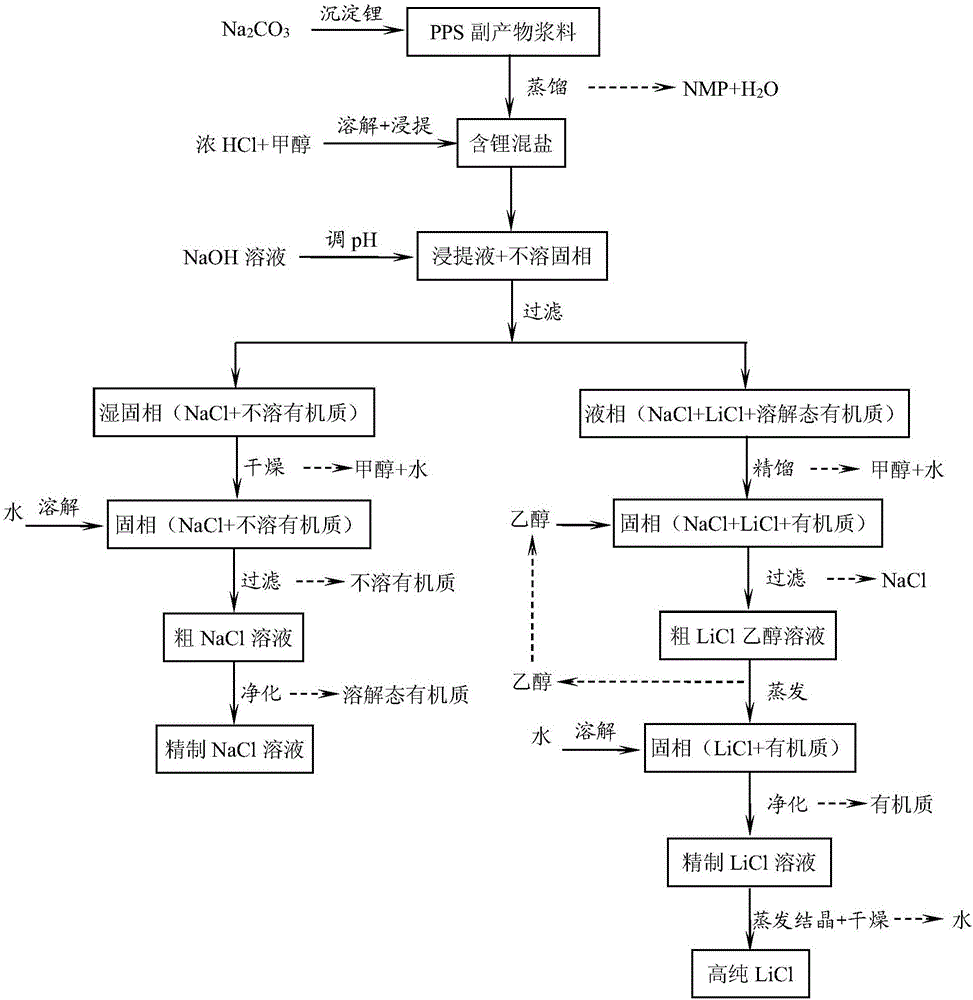

[0024] by figure 1 The shown process scheme recycles the PPS by-product slurry, and after the slurry is distilled and dried under reduced pressure, NaCl, Li 2 CO 3 , organic matter were 80.81%, 12.47% and 6.72%.

[0025] Concentrated HCl and methanol solution were mixed to prepare acidic methanol solution, and the secondary extraction was carried out under the condition that the solid-liquid ratio was 1:1. The single extraction time was 1 hour, and the pH of the solution after the reaction was about 2. Then use 5% NaOH solution to adjust the pH of the leaching solution after the reaction to about 6.5, and separate by filtration to obtain a wet solid phase and a liquid phase.

[0026] The above wet solid phase was air-dried at 70° C. for 30 minutes to remove entrained methanol. Then under the condition of solid-liquid 1:1.3, dissolve and ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com