While-drilling lateral resistivity well test system based on C4D technology and signal detection method of while-drilling lateral resistivity well test system

A resistivity logging and drilling-while-drilling technology, which is applied to wellbore/well components, measurement, earthwork drilling and production, etc., can solve problems such as limited work, and achieve the effects of reducing environmental interference, strong applicability, and reducing design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

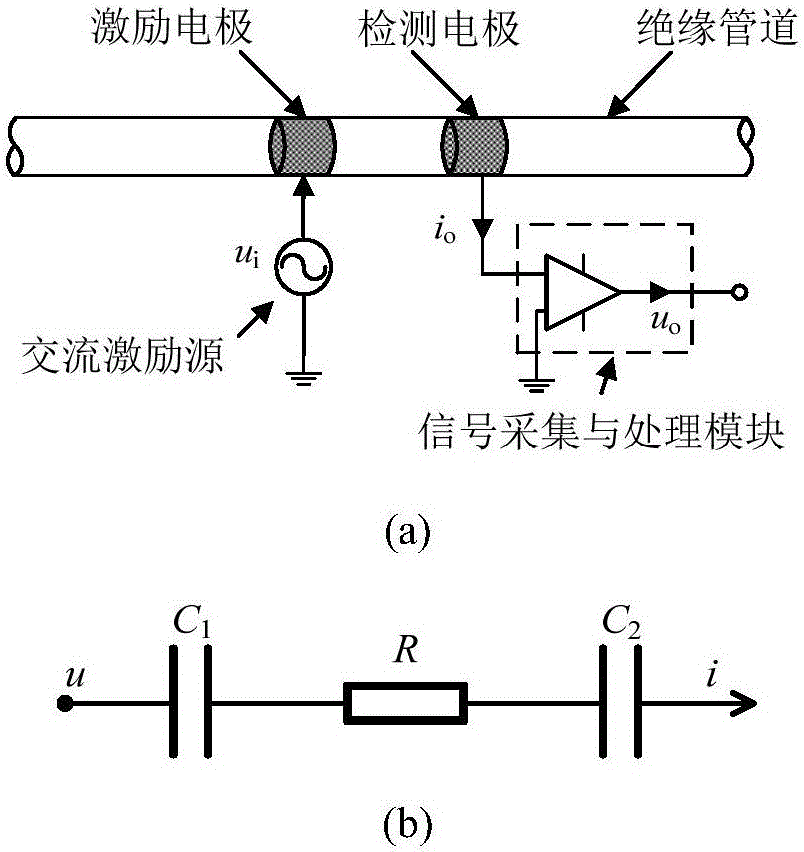

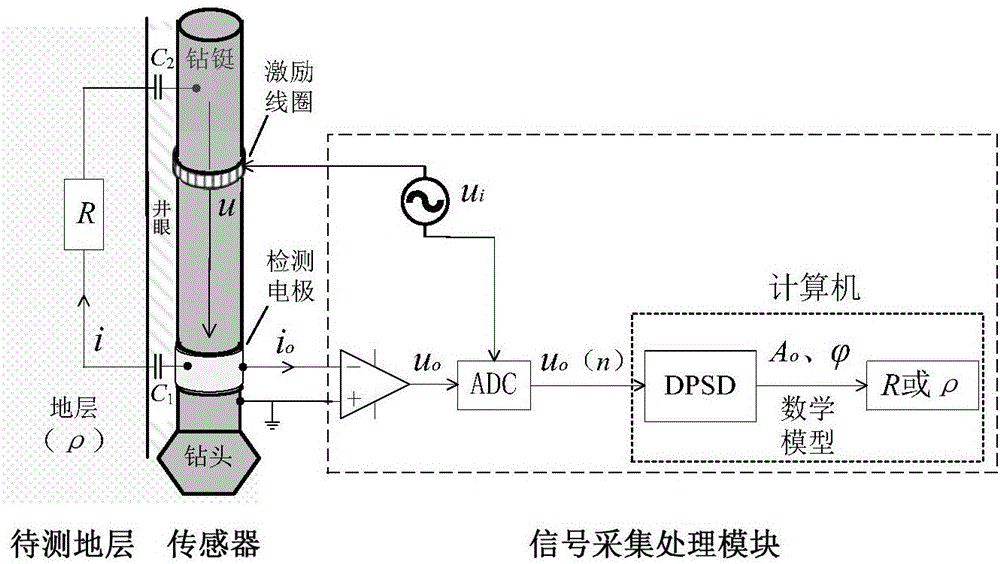

[0031] 1.C 4 DTechnical principle

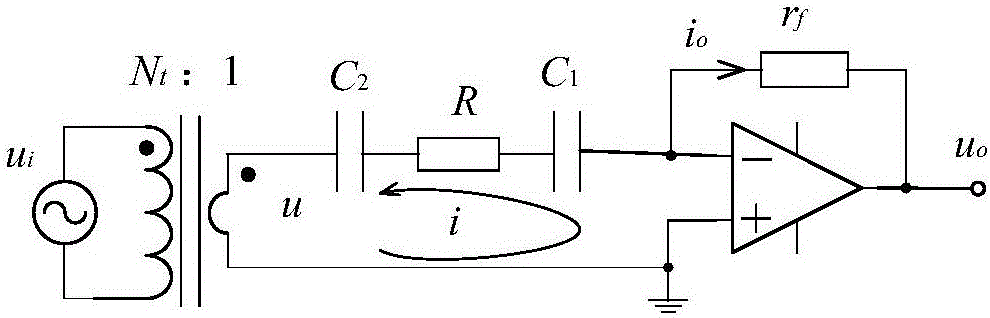

[0032] figure 1 (a) shows a typical C 4D Two-electrode structure. The sensor is mainly composed of an excitation electrode, a detection electrode and an insulating pipe. The excitation electrode and the detection electrode are metal ring electrodes and are set on the outside of the insulating pipe. The two electrodes, the insulating pipe and the measured conductive liquid form an AC measurement path, and its equivalent circuit diagram is as follows: figure 1 (b) shown. Among them, C 1 and C 2 Represent the coupling capacitance formed by the excitation electrode and the detection electrode through the insulating pipe wall and the conductive liquid in the pipe, and R represents the equivalent resistance of the conductive liquid between the two electrodes in the pipe. When an AC voltage signal is applied to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com