On-line monitoring system and method for ultra-long fiber grating writing

A fiber grating and monitoring system technology, applied in cladding optical fiber, optical waveguide light guide, optics, etc., can solve the problems of error reduction and low accuracy, and achieve the effects of overcoming inconsistency, high precision, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

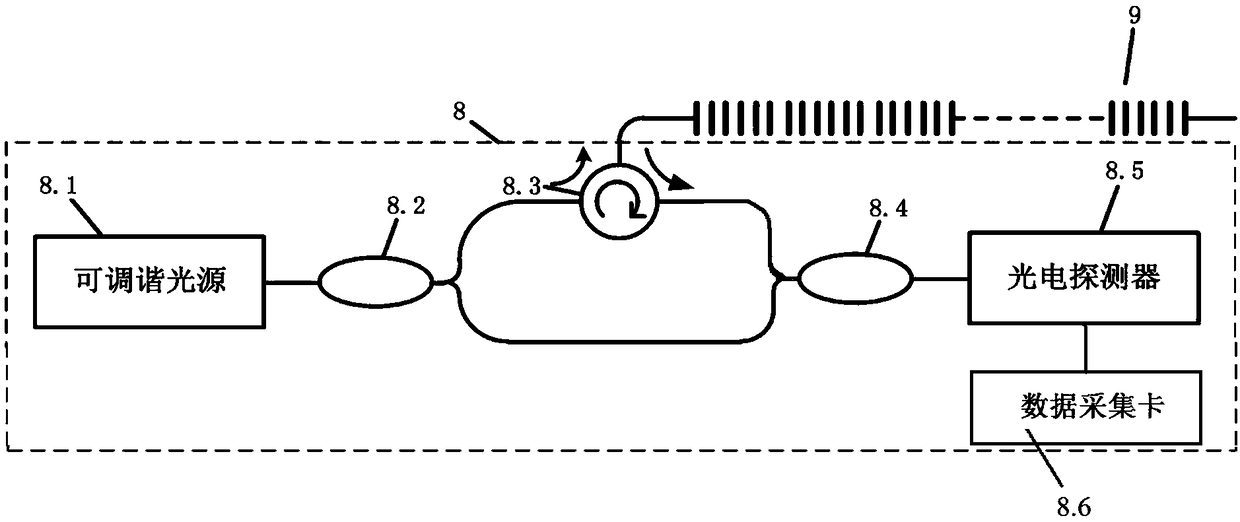

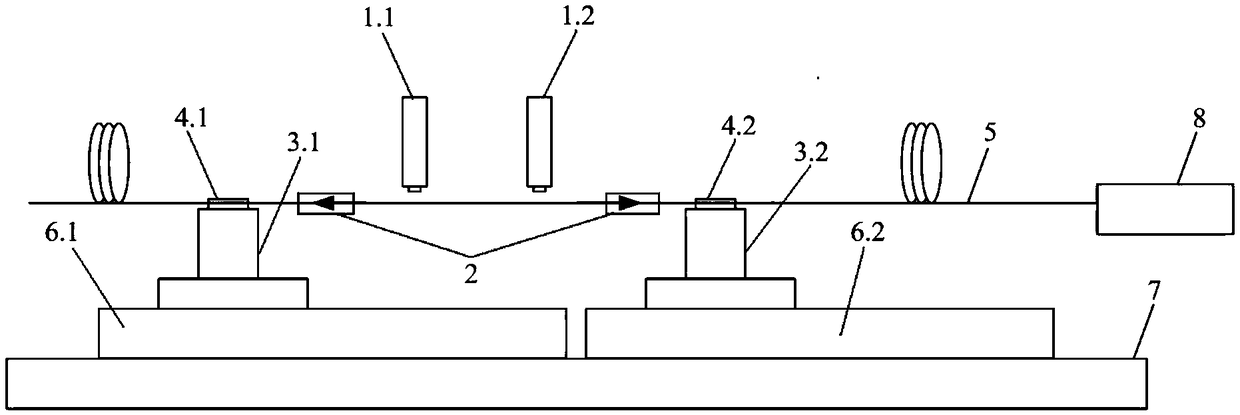

[0033] The ultra-long fiber grating writing online monitoring system designed by the present invention, such as figure 1 and figure 2 As shown, it includes a first microscope 1.1, a second microscope 1.2, a tension gauge 2, a first level 4.1, a second level 4.2, an OFDR detector 8, and the OFDR detector 8 includes a tunable light source 8.1, a first coupler 8.2, circulator 8.3, second coupler 8.4 and photodetector 8.5, wherein the lenses of the first microscope 1.1 and the second microscope 1.2 are respectively aligned with the two ends of the exposure area of the written grating 9 in the fiber grating writing device , the first microscope 1.1 and the second microscope 1.2 are used to observe whether the exposure area of the grating 9 to be written in the optical fiber grating writing device is parallel to the mask plate in the optical fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com