Visual back pressure spray test device used for optical measurement and method thereof

A technology of spray test and optical measurement, which is applied in the direction of measuring device, optical instrument test, machine/structural component test, etc. It can solve problems such as deviation and inability to simulate the back pressure combustion process, so as to achieve true measurement results and avoid secondary The effect of returning fog

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

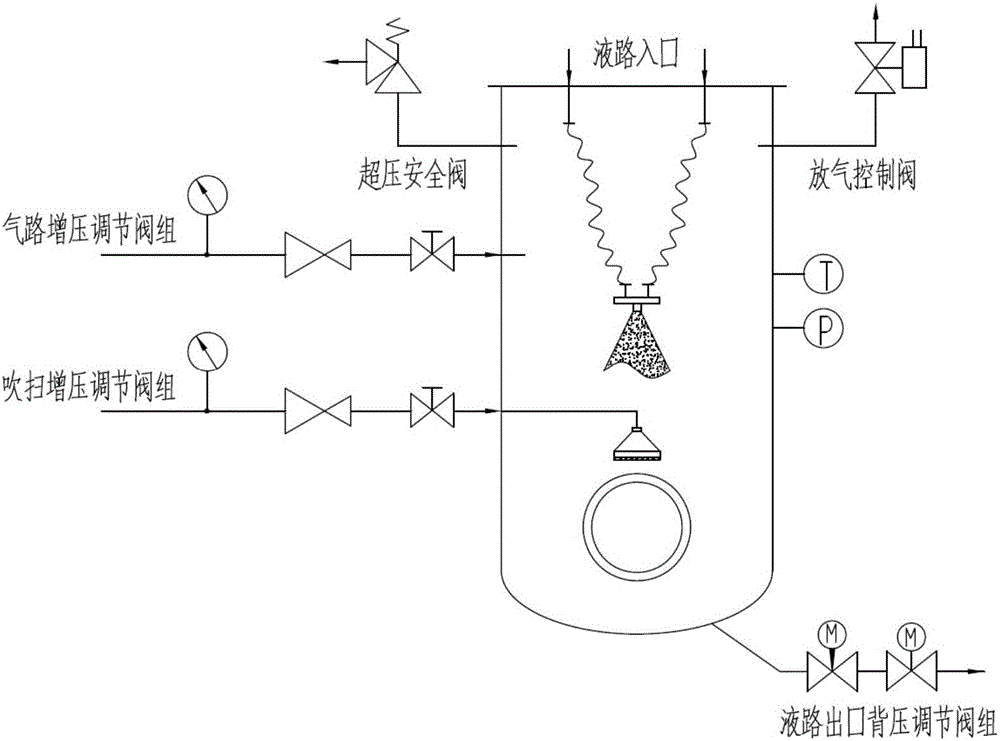

[0060] The tested product is: a certain type of direct current impact nozzle, the rated flow rate is 2g / s, and the back pressure requirement is 0.5±0.05MPa. At the same time, the laser Doppler velocimeter is used to measure and characterize the flow field.

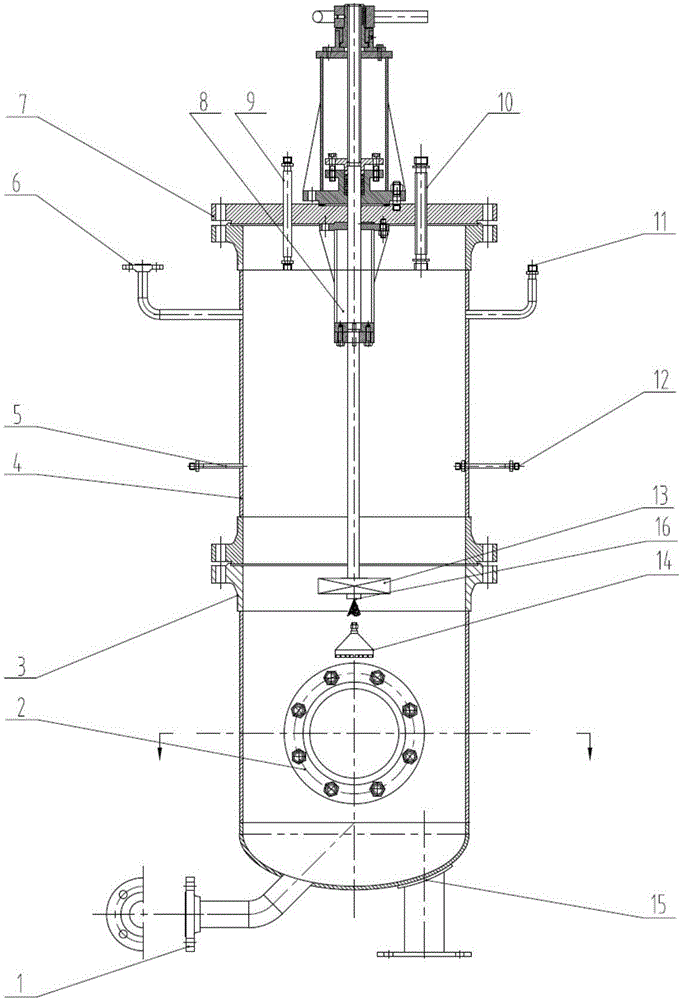

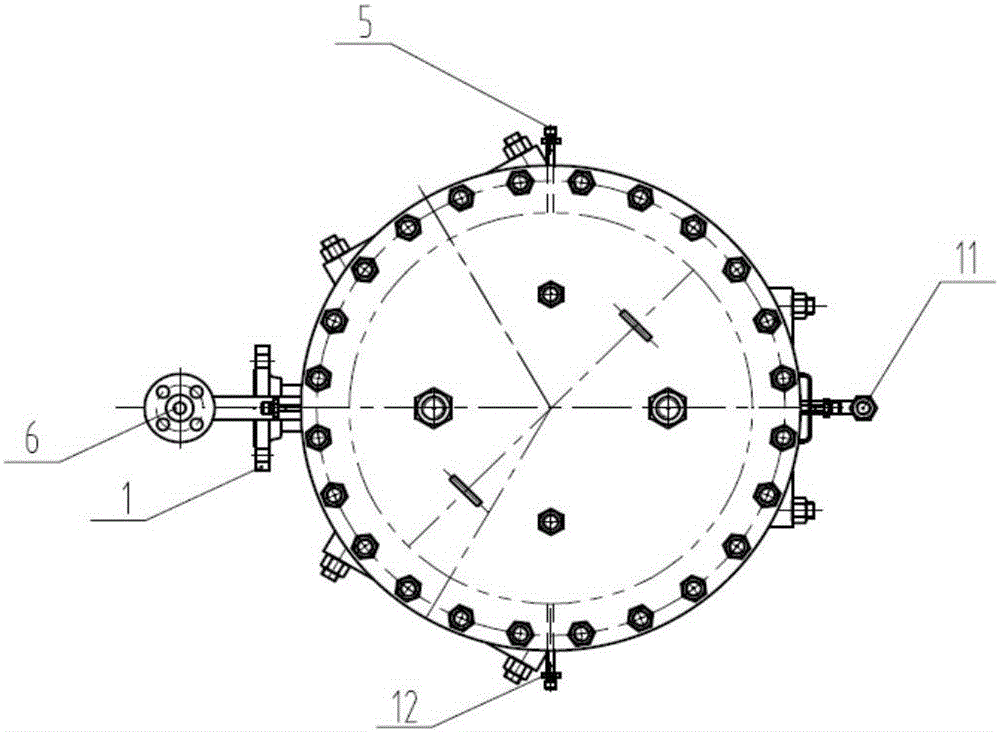

[0061] Such as figure 1 and figure 2 As shown, a visual back pressure spray test device for optical measurement, the test device includes liquid outlet pipeline 1, 3 sets of mirror structure 2, spray cabin 3, cylinder 4, gas pressure inlet Pipeline 5, overpressure safety release outlet pipeline 6, upper cover 7, manual mechanical lifting structure 8, 2 sets of small flow liquid inlet pipelines 9, 2 sets of large flow liquid inlet pipelines 10, air release control Outlet pipeline 11, purge pressurized inlet pipeline 12, six-dimensional electric actuator 13, 3 sets of fan-shaped purge devices 14 and 3 sets of supports 15.

[0062] The spray cabin 3 is a cabin structure with an elliptical head, and the bottom is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com