On-line image visible ferrography reflected light imaging apparatus and method

An imaging device and imaging method technology, applied in image enhancement, image analysis, measurement device and other directions, can solve the problems of interfering abrasive grain imaging, blurred abrasive grain imaging, low image contrast between abrasive grain and background, etc., to improve reliability. effect of sex, elimination of influence, reduction of volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The structure and working principle of the present invention will be described in further detail below in conjunction with the accompanying drawings:

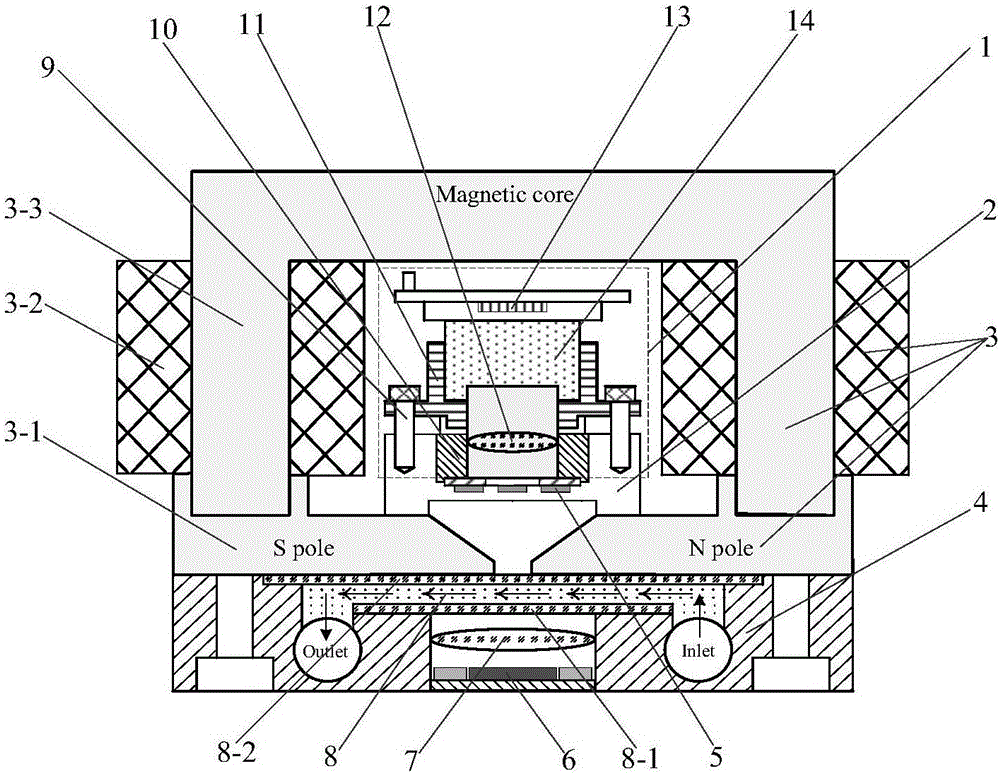

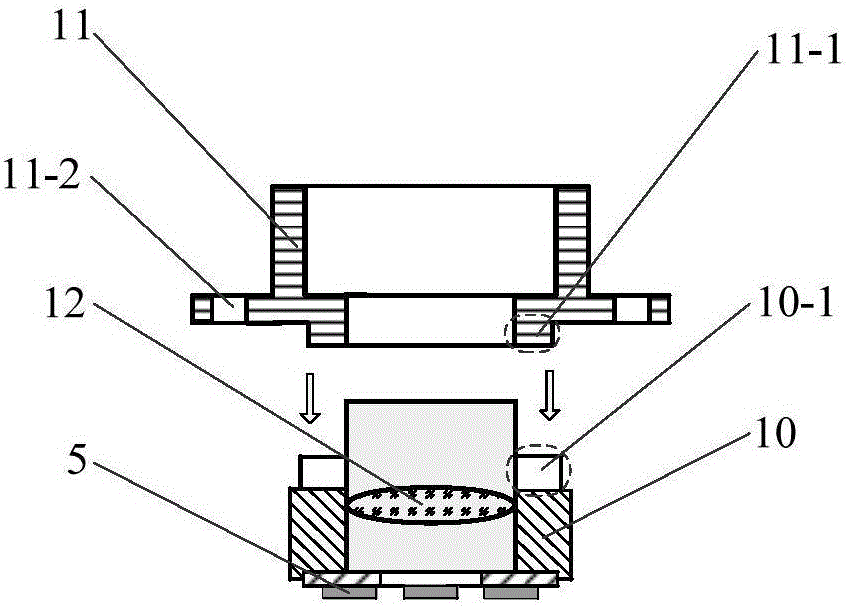

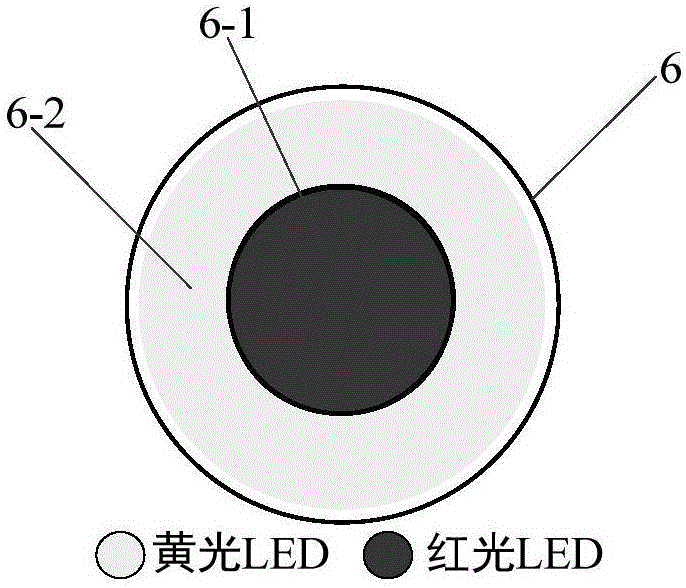

[0042] reference figure 1 , The online image visible ferrograph reflected light imaging device includes a focusing imaging mechanism 1, a connecting seat 2, a reflective light source 5 and a transmission light source 6. The imaging device of the present invention is assembled and fixed with the excitation module 3 and the flow channel 4 to form an online reflective light imaging Image visible ferrograph probe, in which the excitation module 3 is composed of a magnetic pole 3-1, an excitation coil 3-2 and an iron core 3-3. The flow channel 4 is fixed directly under the magnetic pole 3-1, focusing and imaging mechanism 1 and reflection The light source 5 is fixed on the side of the flow channel 4 close to the slide through the connecting seat 2 with screws, the transmission light source 6 is installed on the other side of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com