A kind of Vajra Bodhi seed encapsulation device and method

A technology of bodhi seeds and king kong, which is applied in the field of Wenwan processing and production, can solve the problems of not having, not solving the problem of fast wrapping, etc., and achieve the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0034] This embodiment is an embodiment of a rudraksha seed wrapping device.

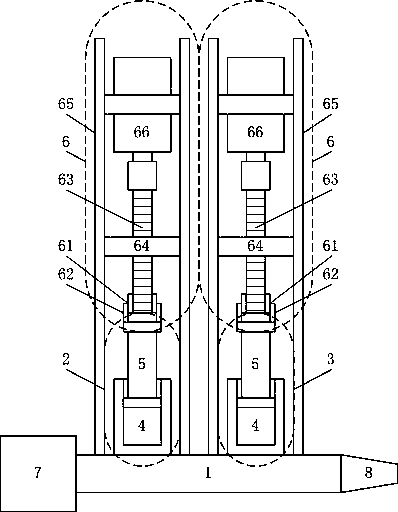

[0035] The Vajra Bodhi seed wrapping device of the present embodiment, the structure schematic diagram is as figure 1 shown. This Rudraksha bodhi patina device comprises a spray pipe 1, an oil bottle 2 and a liquid storage bottle 3 installed on the spray pipe 1, and the oil bottle 2 includes a fixed end 4 and a propulsion end 5 connected with the needle hole of the spray pipe 1, Lard oil is housed in the oil bottle 2; The liquid storage bottle 3 includes a fixed end 4 and a propelling end 5 connected with the injection pipe 1 pinhole, and the aqueous solution of sodium chloride, urea, lactic acid, fatty acid is housed in the liquid storage bottle 3; The inner end of the propulsion end 5 is provided with a rubber plug, and the outer end is provided with a propulsion structure 6; one side of the spray pipe 1 is provided with an air pump 7, and the other side is provided with a nozzle 8.

specific Embodiment 2

[0036] This embodiment is an embodiment of a rudraksha seed wrapping device.

[0037] The Vajra Bodhi wrapping device of the present embodiment, on the basis of the specific embodiment 1, further defines that the propulsion structure 6 includes a bearing 61, and the protruding end 62 connected with the outer ring of the bearing 61 with an interference fit, passes through the inner ring of the bearing 61. The rotating end 63 connected by Ying fit, the rotating end 63 is covered with thread, the nut 64 of fixed position is installed on the rotating end 63, and the nut 64 is fixedly installed on the track 65, the motor 66 that controls the rotating end 63 to rotate along the track 65 direction movement.

specific Embodiment 3

[0038] This embodiment is an embodiment of a rudraksha seed wrapping device.

[0039] The Vajra Bodhi wrapping device of this embodiment, on the basis of the specific embodiment 1, further defines that along the direction of the air flow, the inside of the nozzle 8 is a structure that is first thick and then thin.

[0040] The structural design of the first thick and then thin structure makes the gas pressure further increase, the speed of the gas ejected from the nozzle 8 is faster, and the rotating speed of the rudraksha is also accelerated, thereby increasing the wrapping speed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com