Preparation method and application method of bamboo vinegar decomposition liquid

An application method and a decomposing solution technology are applied in the field of preparation of bamboo vinegar decomposing solution, which can solve the problems of secondary pollution, acetone has no obvious scavenging effect, and restricts the action of photocatalyst, and achieves large specific surface area and surface energy, improved scavenging effect, Strong adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

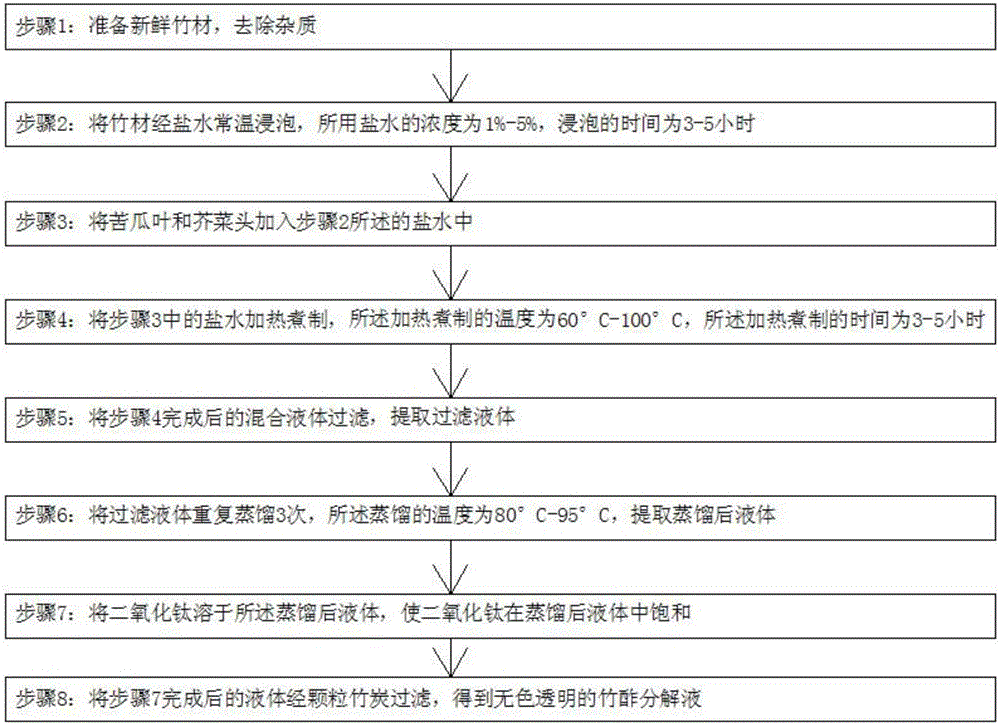

[0036] A kind of preparation method of bamboo vinegar decomposition liquid, comprises the steps:

[0037] Step 1: Prepare fresh bamboo and remove impurities;

[0038] Step 2: Soak the bamboo in salt water at room temperature, the concentration of the salt water used is 1%-5%, and the soaking time is 3-5 hours;

[0039] Step 3: Add bitter gourd leaves and mustard heads to the brine described in step 2;

[0040] Step 4: heating and boiling the brine in step 3, the temperature of the heating and boiling water is 60°C-100°C, and the heating and boiling time is 3-5 hours;

[0041] Step 5: Filtrating the mixed liquid after step 4 is completed, and extracting the filtered liquid;

[0042] Step 6: Distill the filtered liquid three times, the temperature of the distillation is 80°C-95°C, and extract the liquid after distillation;

[0043] Step 7: dissolving titanium dioxide in the distilled liquid, so that the titanium dioxide is saturated in the distilled liquid;

[0044] Step 8: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com