Preparation method for modified sepiolite and application of sepiolite in environmental restoration

A sepiolite and modification technology, applied in the field of preparation of modified sepiolite, can solve the problems of complex process, insufficient environmental protection and high preparation cost, and achieve the effects of less dosage, easy promotion and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] This embodiment provides a method for preparing an organically modified sepiolite heavy metal cadmium adsorbent, comprising the following steps:

[0025] a. Mix 10g of natural sepiolite with deionized water at a mass ratio of 1:20, stir to form a sepiolite suspension and let stand for 24 hours to swell the sepiolite.

[0026] b. Add 1.0 g of sodium diethyldithiocarbamate into the above swollen solution, stir at 60° C. for 2 h, and then continue stirring at room temperature for 24 h.

[0027] c. Put it in a funnel, wash the solid 6 times with deionized water until the filtrate does not contain sodium diethyldithiocarbamate, dry at 60°C for 12 h, and grind to obtain organically modified sepiolite.

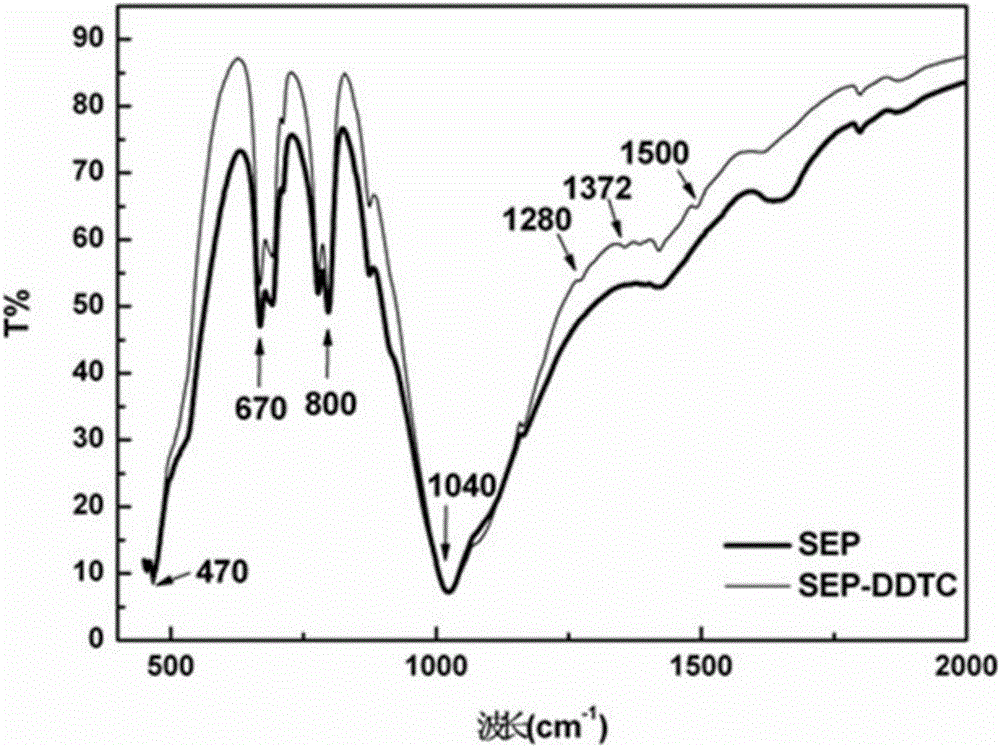

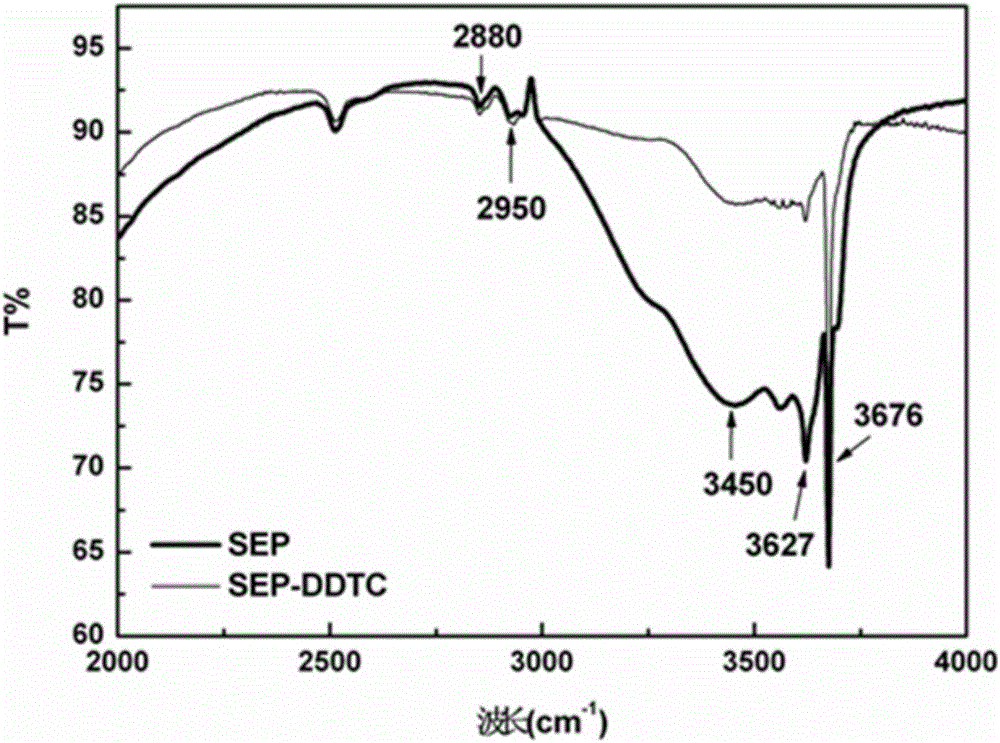

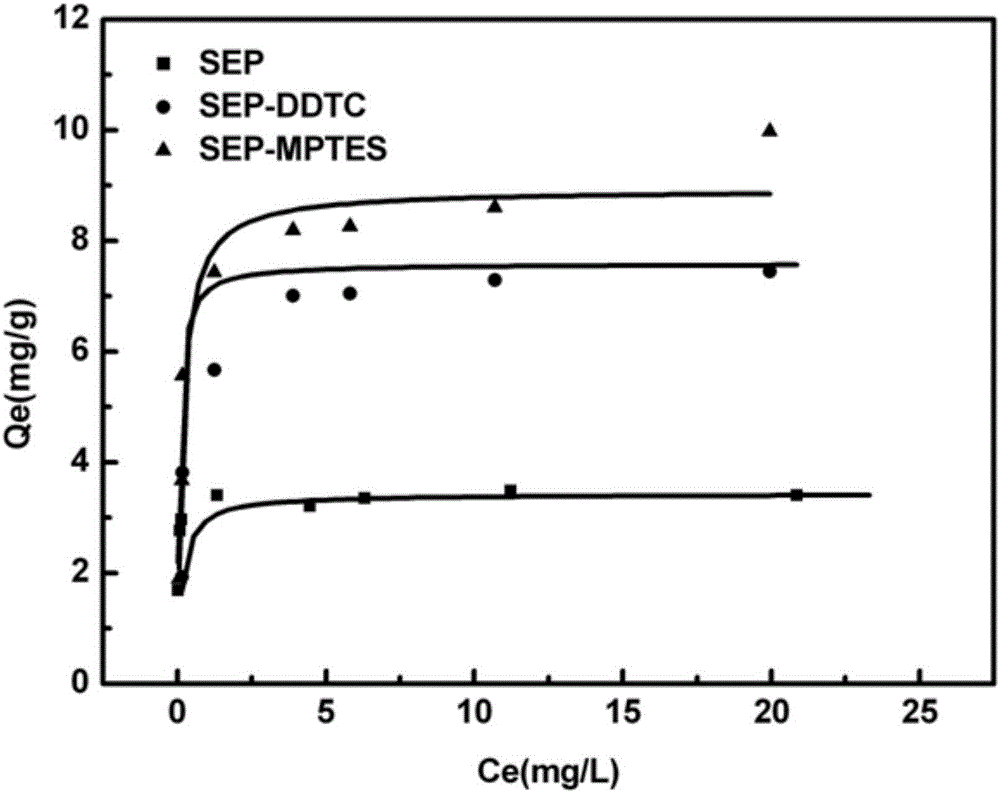

[0028] Such as Figure 1a and Figure 1b As shown, 470 cm -1 is Mg-O, 670 cm -1 and 800 cm -1 It is Si-O, 3676cm -1 and 3627cm -1 is-OH, 3450 cm -1 It is zeolite water, 1040cm -1 is the Si-O-Si vibration peak. 1372cm -1 and 1500cm -1 are the unique C-S and C-N vi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com