A combined use method of a double-series slide table

A tandem and sliding table technology, applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problems of small application range, poor repeat positioning accuracy, small load, etc., and achieve simple structure and high precision High, low manufacturing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

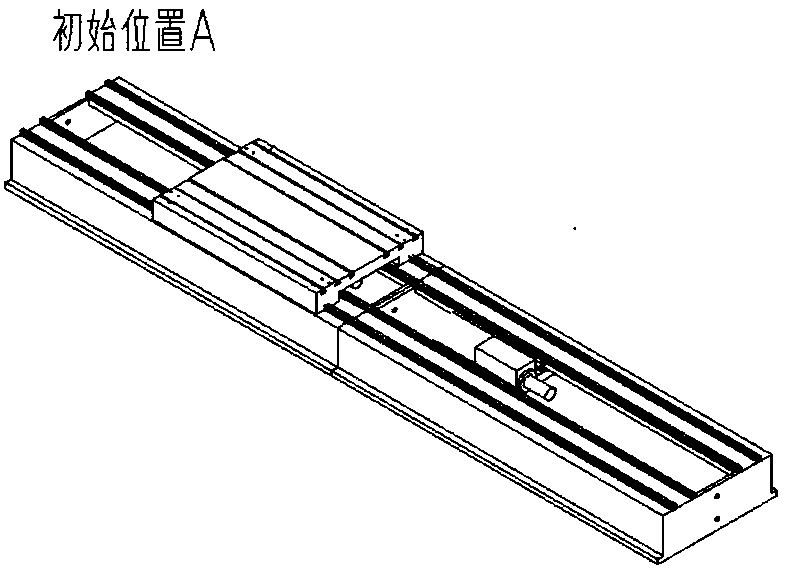

[0037] Such as Figure 1-Figure 5 As shown, the combined use method of the double-tandem slide table of this patent includes:

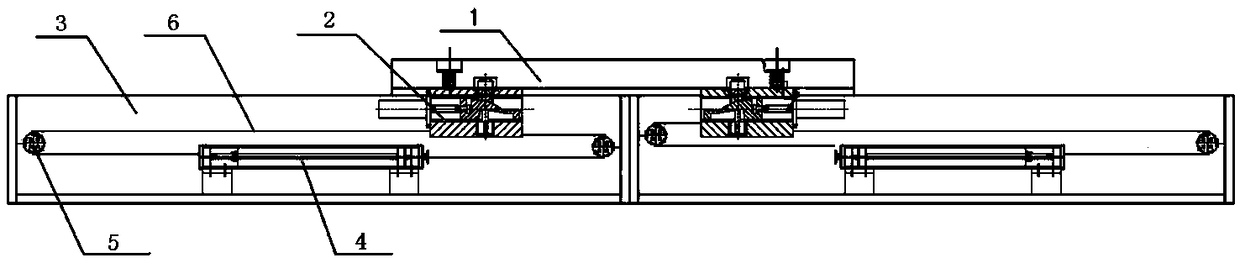

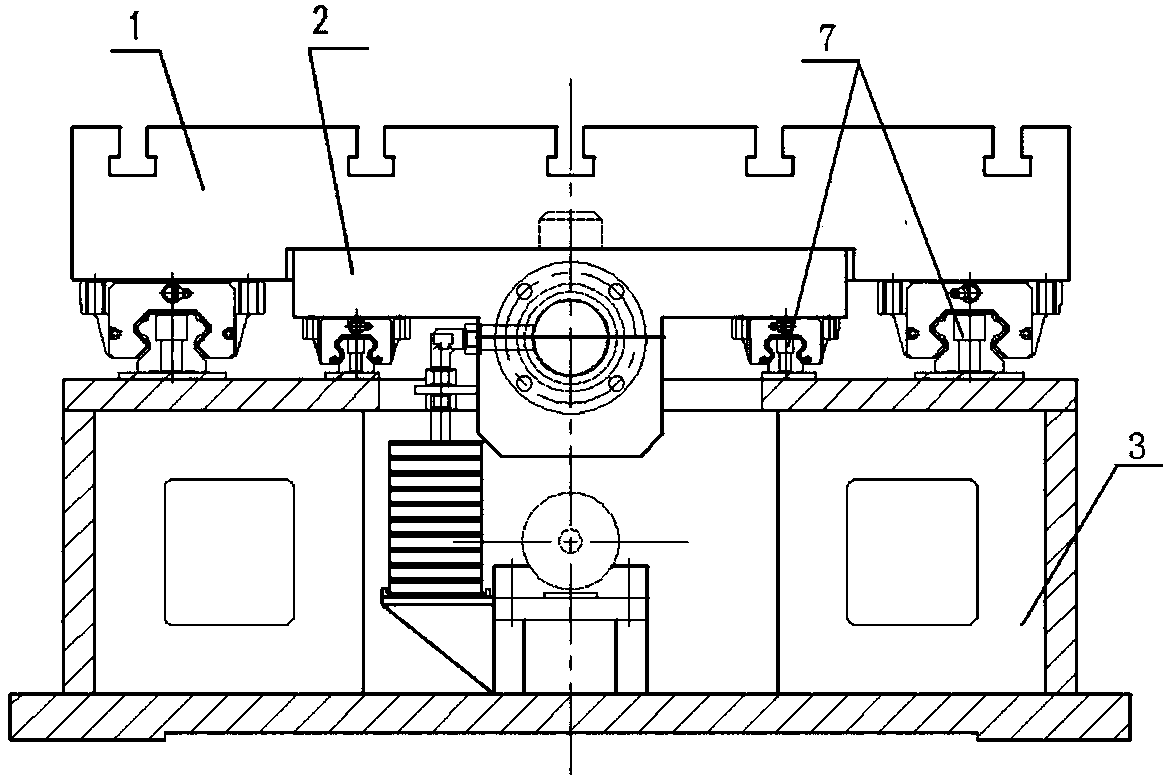

[0038] Make two sliding table mechanisms to be combined respectively; set driving oil cylinders 4 at the bottom of the sliding table seats 3 of the two sliding table mechanisms, and set a plurality of linear guide rails 7 at the upper end of the sliding table seats 3, and each linear guide rail 7 is distributed in parallel; the driving oil cylinders 4 are Left and right two-way output hydraulic cylinder is adopted.

[0039] On the left and right sides of the driving oil cylinder 4 at the bottom of the sliding platform seat 3, a left transmission mechanism and a right transmission mechanism are respectively arranged; the left transmission mechanism includes a drag cable 6 and a fixed pulley 5; After changing direction through the left transmission mechanism and the right transmission mechanism, it is connected with the same driving block 2, so that th...

Embodiment 2

[0052] The technical solution in embodiment 2 is basically the same as the technical solution in embodiment 1, the difference is that the telescopic fixing mechanism of the drive block 2 is a clamping device, and the docking mechanism of the slide body 1 is a clamping device corresponding to the clamping device. noodle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com