Expansion machine refrigeration subcooling and nano particle jet flow minimal quantity lubrication supply system

A technology of micro-lubrication and nano-particles, applied in the direction of manufacturing tools, injection devices, liquid injection devices, etc., can solve the problems of no refrigeration principle and in-depth improvement of structure, increase the operating burden of air compressors, and large compressed air consumption, etc., to achieve Solve the stability problem, improve the grinding temperature is too high, reduce the effect of grinding thermal damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0100] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

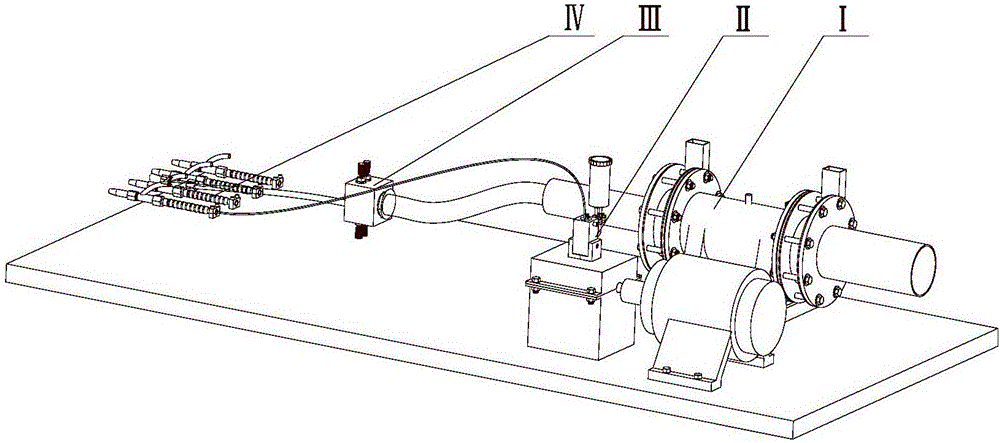

[0101] In one embodiment, the expander refrigerated low-temperature cooling nanoparticle jet minimal quantity lubrication supply system includes expander I, nanofluid minimal quantity lubrication supply system II (MQLSS for short) and external mixing nozzle IV (nozzle for short)

[0102] Such as figure 1 As shown, in another embodiment, the expander refrigeration low temperature cooling nano particle jet minimal quantity lubrication supply system further includes a gas distribution control valve III (GDCV for short).

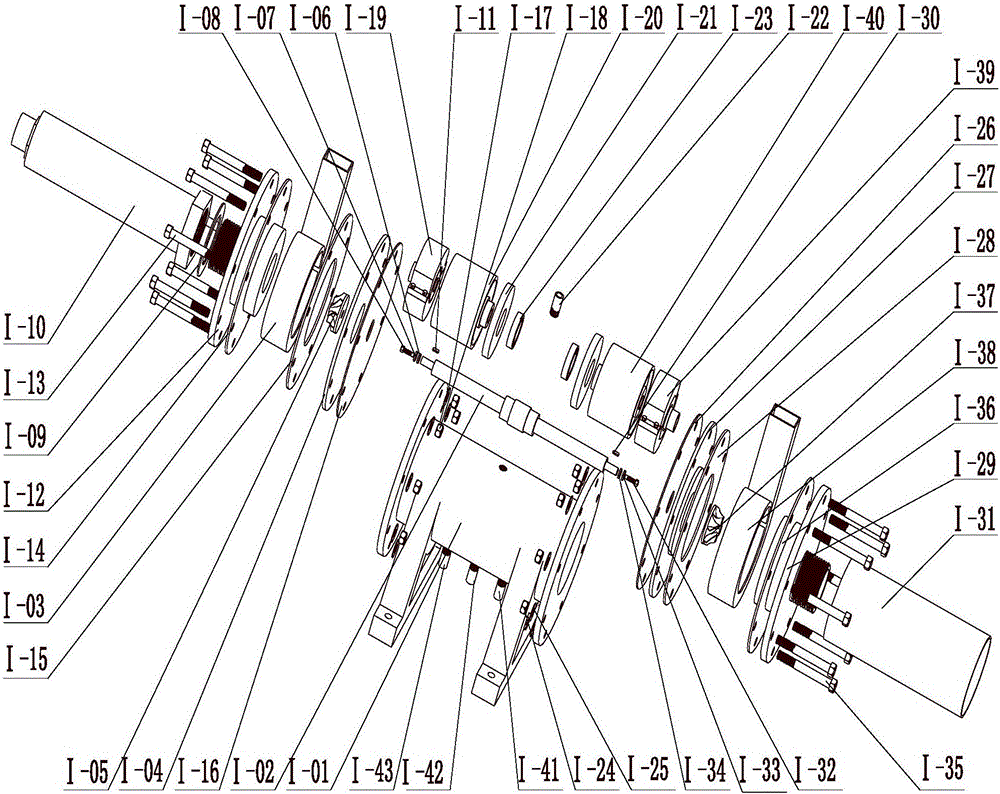

[0103] Such as figure 2 as shown, figure 2 It is the explosion diagram of the turbo expander and the display diagram of each component.

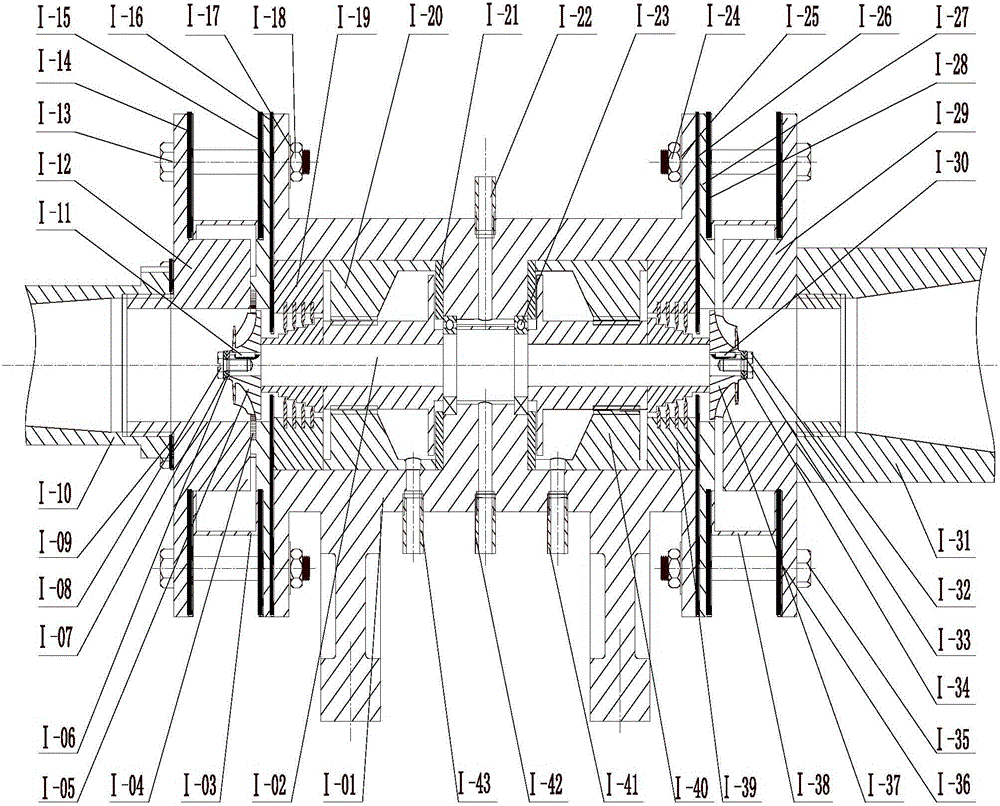

[0104] Such as image 3 , image 3 (a) and image 3 As shown in (b), the expander impeller I-05, volute I-03, labyrinth seal combination I-19, spiral seal combination I-20, and deep groove ball bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com