Combined rubber and plastic corrugated board and RFID label turnover box manufactured by using combined rubber and plastic corrugated board

A corrugated board, turnover box technology, applied in rubber layered products, bottle/can parts, synthetic resin layered products, etc. The modularity of corrugated board turnover box and other issues, to achieve the effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] Below is working principle and working process of the present invention:

[0084] The bottom plate of the RFIT label turnover box of the present invention directly contacts the bearing surface, and the bottom plate of the upper layer directly contacts the cover plate of the lower layer when stacking, so that the cushioning effect is good and the goods are not easy to be damaged. The sealing rubber strip 4 of the RFIT label turnover box of the present invention not only plays a role of sealing, but also plays a role of cushioning against drop impact and vibration impact. The side and bottom of the RFIT label turnover box of the present invention are three-sided vertical profiles 5 and two-sided vertical profiles 6, made of plastic, aluminum or steel, and have high side pressure strength and strong bearing capacity for stacking.

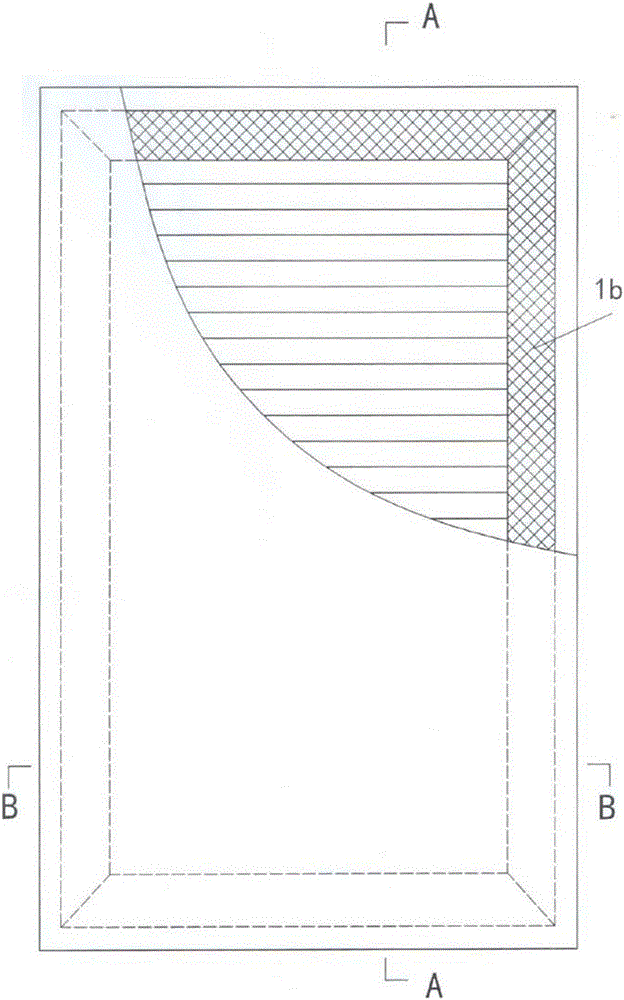

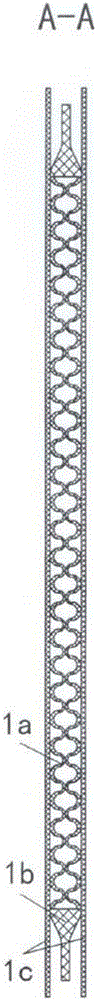

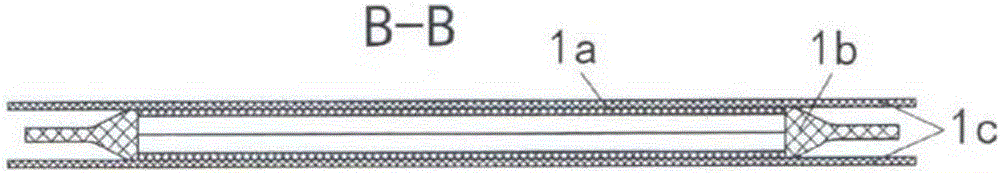

[0085] The RFIT label turnover box of the present invention selects and optimizes the shape, size, material and processing method of the corrug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com