Caterpillar band pumping type dredging robot

A robot and pumping mechanism technology, applied to tracked vehicles, motor vehicles, earth movers/excavators, etc., can solve the problems of low dredging efficiency, unreliable sludge, limited conveying distance and reliability, etc., to achieve The structure is simple and reliable, and the effect of expanding the application space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

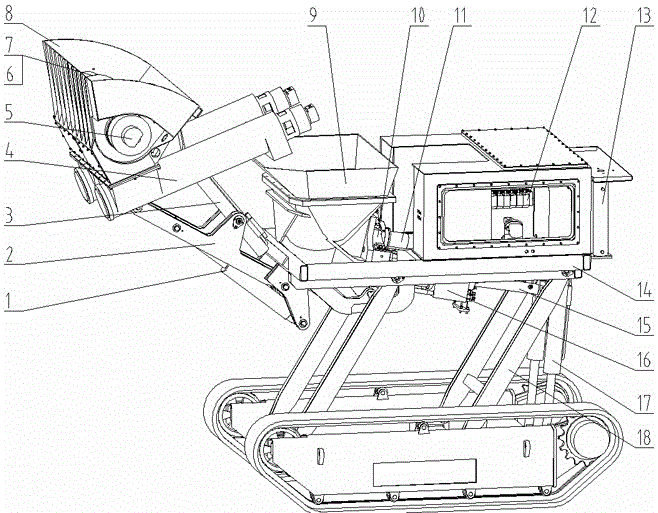

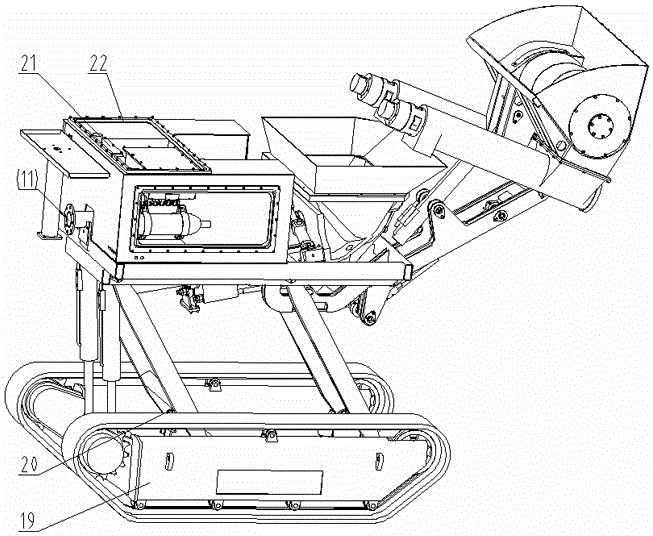

[0020] Specific embodiments of the present invention are described in detail below in conjunction with accompanying drawings, as figure 1 As shown, the crawler pumping type dredging robot of the present invention includes a bucket assembly, a boom lifting mechanism, a pumping mechanism, a video assembly, a control cavity assembly, an underframe assembly, an underframe lifting mechanism, Track assembly, ground control system;

[0021] The bucket assembly includes a bucket 8, a drive motor 5, a stirring shaft 6, left and right-handed stirring blades 7, and a conveyor assembly 4. The left-handed and right-handed stirring blades 7 are welded on the stirring shaft 6, and the driving motor 5 Drive the stirring shaft 6 to rotate the silt excavated by the agitating bucket 8. The silt will be discharged to the conveyor assembly 4 through the discharge hole on the bucket 8, and the conveyor assembly 4 will transport the silt to the pumping mechanism in the hopper 9;

[0022] Further, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com