Zigzag falling transporting device capable of sliding by relying on self-gravity

A conveying device and self-gravity technology, which is applied in the field of workpiece drop conveying, can solve the problems of curved appearance, small space occupation, large space occupation, etc., and achieve the effect of uniform connection drop, easy installation and debugging, and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

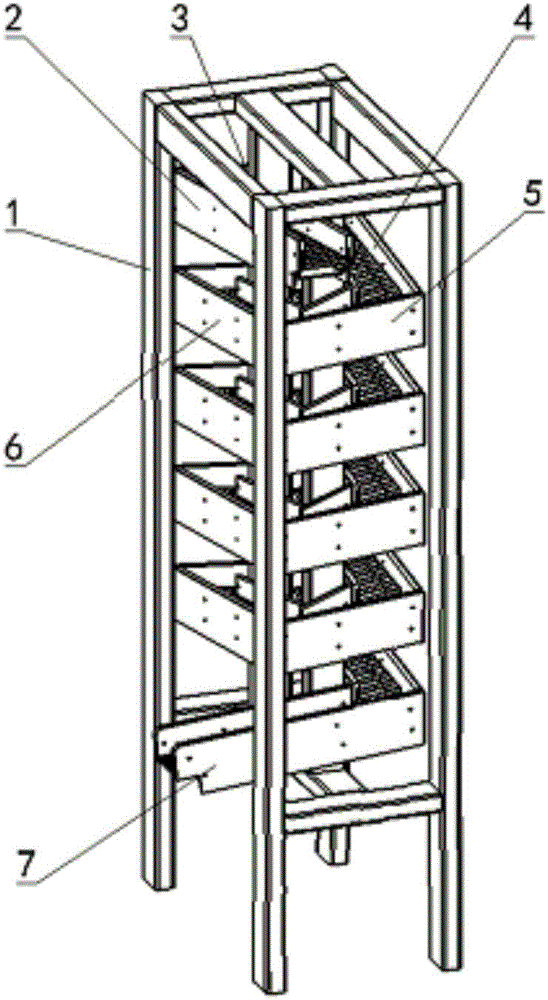

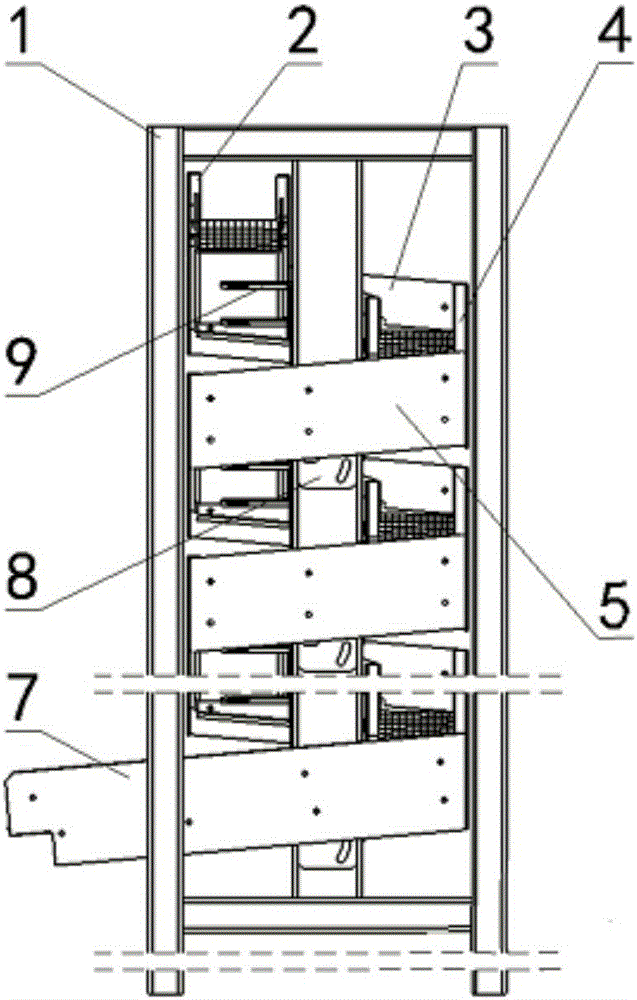

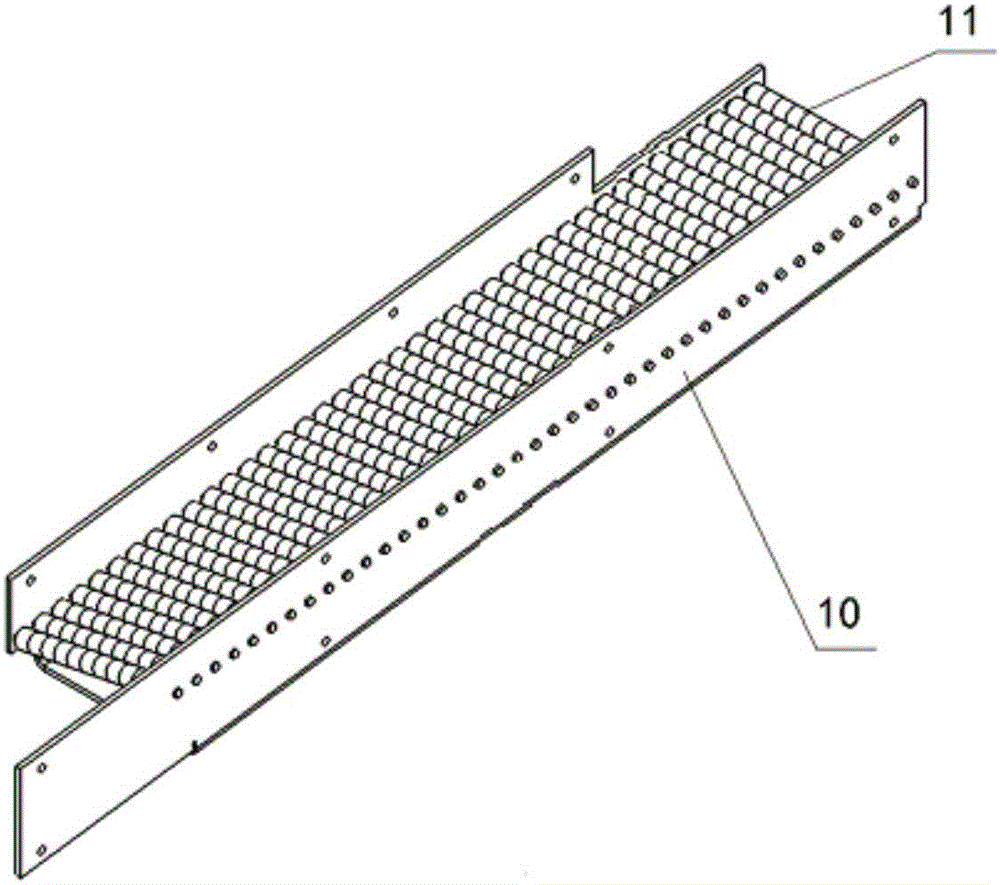

[0024] Such as Figure 1 to Figure 4 As shown, the return-shaped descending conveying device relying on self-gravity sliding of the present invention comprises installation frame 1, feeding slideway 2, short slideway one 3, long slideway one 4, short slideway two 5, long slideway two 6. The discharge slideway 7, the adjustable angle mounting plate 8, the adjustable angle support plate 9, the installation frame 1 is a square frame, and a column is arranged in the middle of the installation frame 1.

[0025] Such as figure 1 , figure 2 Shown, each group of slideways of the present invention is made up of short slideway one 3, long slideway one 4, short slideway two 5, and long slideway two 6, and each group of slideways surrounds the installation frame from top to bottom respectively 1, and the slideways are all inclined, and the tail of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com