Hose microporous aerator for oxygenating and stirring natural water and aquatic breeding water

A microporous aerator, aquaculture water technology, applied in water aeration, water/sludge/sewage treatment, water treatment parameter control, etc. Problems such as lower laying, low oxygenation efficiency and power efficiency, and large safety risks can achieve the effect of avoiding leakage and discharge accidents, reducing operation and maintenance costs, and operating safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

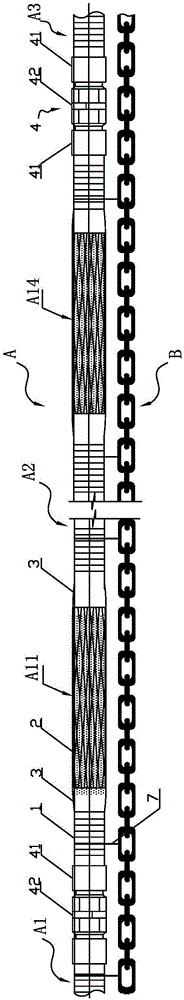

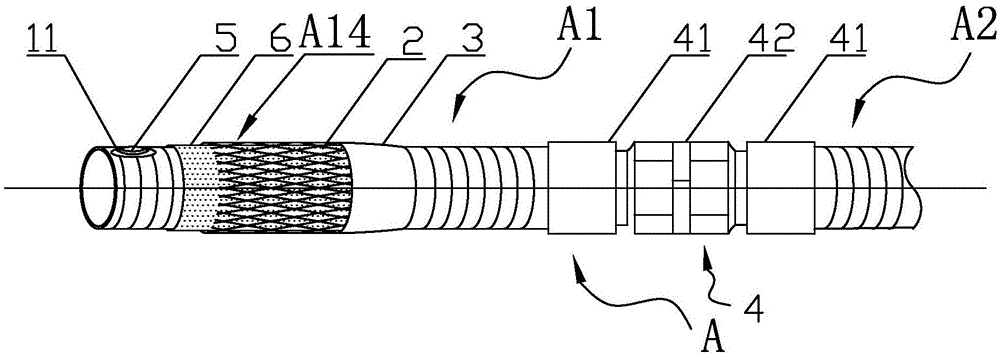

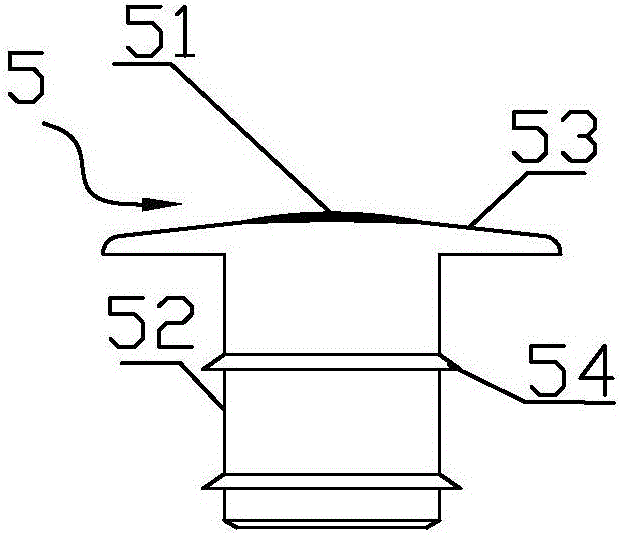

[0028] Figure 1 ~ Figure 4 It shows a kind of hose microporous aerator for oxygenating and agitating natural water bodies and aquaculture water bodies. Heavy object B, the main body A of the hose microporous aerator is composed of several hose microporous aerator units A1, A2, A3, etc. connected in series, and the hose microporous aerator unit is provided with a main The air supply hose 1 has several valve holes 11 evenly distributed on the pipe wall along the length direction of the main air supply hose 1. In actual production, the main air supply hose 1 adopts a high-pressure rubber tube or a steel wire rubber hose, so it has It has high strength to withstand internal and external pressure and has a certain degree of flexibility, which can be moderately bent. Set 3-6 valve holes on the wall of the main air supply hose, and the distance between adjacent valve holes is 0.6-1.2m. In this example, four valve holes 11 are set, and the distance between adjacent valve holes is 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com