Movable high-efficiency oily sewage treatment process

A technology for the treatment of oily sewage, applied in water/sewage treatment, flotation water/sewage treatment, water/sewage treatment equipment, etc., it can solve the problems of high investment and production and treatment costs in centralized station treatment projects, and achieve high efficiency and safety. Economical and efficient development, short residence time, and the effect of reducing production processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

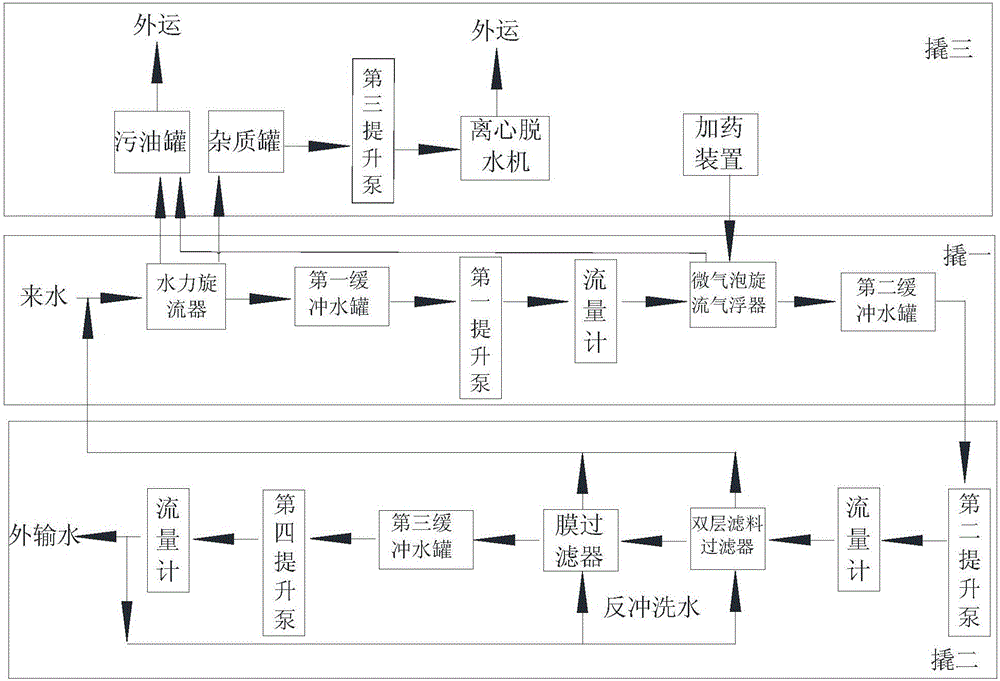

[0016] Firstly, the oily sewage generated after the oil-water separation of the oilfield production fluid enters the hydrocyclone through the water supply pipeline for oil-water separation, and the effluent treated by the hydrocyclone enters the first buffer water tank, and the water in the first buffer water tank After being lifted by the pump and passing through the flow meter, it enters the micro-bubble cyclone air flotation device for further separation of oil, water and impurities, and the water from the micro-bubble cyclone air flotation device enters the second buffer water tank; The second lifting pump is lifted and measured by the flow meter and enters the double-layer filter material filter for filtration. The effluent filtered by the double-layer filter material filter enters the modified polytetrafluoroethylene membrane filter, and the modified polytetrafluoroethylene membrane filter Water from the filter (or line box membrane fine filter) enters the third buffer wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com