A kind of preparation method of wall filling material

A filling material and wall technology, applied in the field of biomass-based building materials preparation, can solve the problems of limited protection objects, human toxicity and environmental pollution, and difficult and durable protection, so as to improve living comfort, simple preparation process and reproducible strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

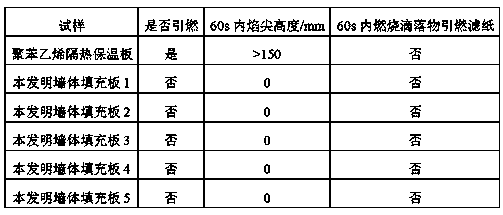

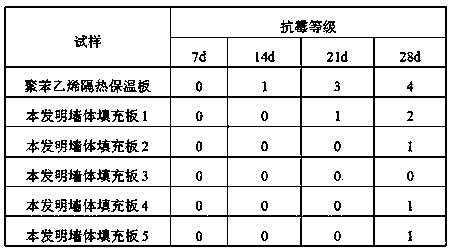

Examples

Embodiment 1

[0029] 1.00 cubic meters of wheat starch, 0.50 cubic meters of rice bran powder, 0.50 cubic meters of sawdust powder, 1.00 cubic meters of straw ash powder, 1.50 cubic meters of red clay powder, and 0.10 cubic meters of slaked lime powder were passed through a 40-mesh sieve at room temperature of 25°C. , and then together with 3.00 cubic meters of water, put it into a kneader, energize and knead and mix evenly, then send the resulting uniform mixture into the mold equipment and extrude it under a pressure of 50kN to obtain a green tire product; then place the green tire product at 650 ℃ under a nitrogen atmosphere for 1.5 hours; finally discharged and cooled to obtain a wall filling board 1 with a length of 100 cm x width of 60 cm x thickness of 9 cm.

Embodiment 2

[0031] At room temperature of 25°C, first pass 1.00 cubic meters of wheat starch, 1.00 cubic meters of rice bran powder, 0.75 cubic meters of straw ash powder, 1.00 cubic meters of red clay powder, and 0.20 cubic meters of slaked lime powder through a 40-mesh sieve, and then mix with 2.00 cubic meters of water Together, put it into a kneader, turn on the electricity and knead and mix evenly, then send the obtained uniform mixture into the mold equipment and extrude it under a pressure of 50kN to obtain a green tire product; hours; finally discharging and cooling to obtain a wall filling board 2 with a length of 100 cm × width of 60 cm × thickness of 9 cm.

Embodiment 3

[0033] At room temperature of 25°C, 1.00 cubic meters of wheat starch, 0.75 cubic meters of rice bran powder, 0.25 cubic meters of sawdust powder, 0.50 cubic meters of straw ash powder, 1.50 cubic meters of bentonite powder, and 0.30 cubic meters of slaked lime powder were passed through a 40-mesh sieve. Then put it into the kneader together with 2.50 cubic meters of water, turn on the electricity and knead and mix evenly, then send the obtained uniform mixture into the mold equipment and extrude it under the pressure of 50kN to obtain the green tire product; then place the green tire product at 750°C Calcined under nitrogen atmosphere for 0.5 hours; finally discharged and cooled to obtain a wall filling board 3 with a length of 100 cm x width of 60 cm x thickness of 9 cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com