Polyaniline nano particle/two-dimensional layered titanium carbide composite material and low-temperature preparation method of polyaniline nano particle/two-dimensional layered titanium carbide composite material

A nanoparticle, two-dimensional layered technology, which is applied in the field of polyaniline nanoparticle/two-dimensional layered titanium carbide composite materials and its low-temperature preparation, can solve problems such as damage, and achieve simple and safe operation, safe experimental process, and wide application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1) Refined powder

[0045] Refinement of ternary layered Ti with a purity greater than 97% by high energy ball milling 3 AlC 2 Ceramic powder, ball milling condition: the mass ratio of ball stone, mixing material and ball milling medium (dehydrated alcohol) is 10:1:1, and ball milling speed is 400r / min, and the time of high-energy ball milling is 4h, then the gained solid-liquid mixture is in Dry at 50°C to obtain Ti with a particle size of about 8 μm 3 AlC 2 Ceramic powder.

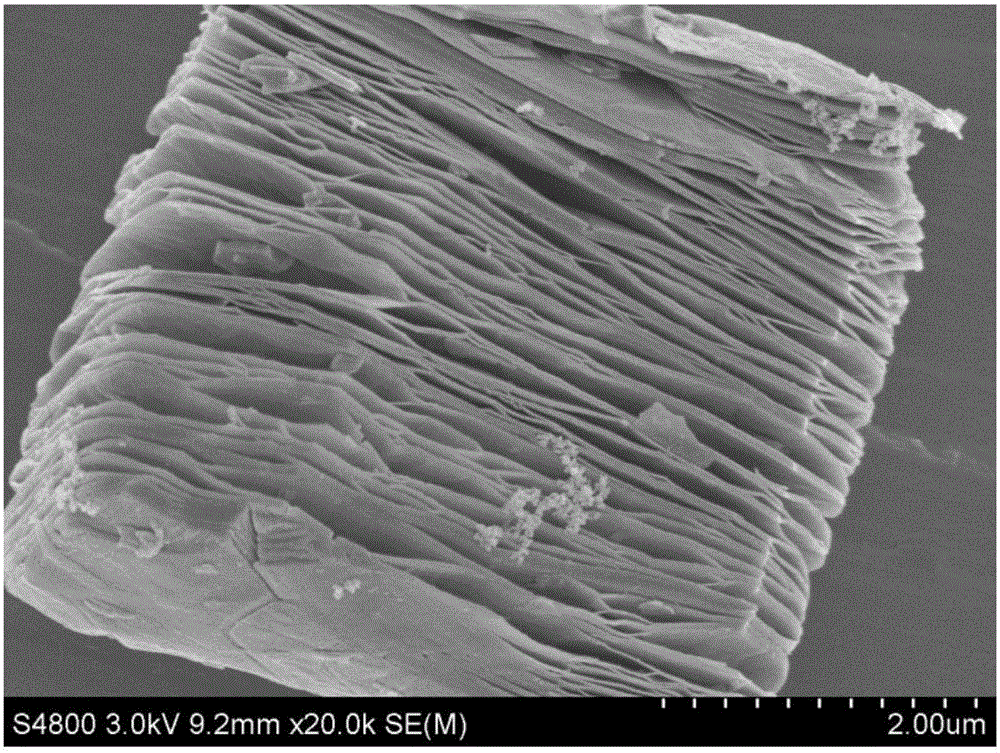

[0046] 2) Two-dimensional layered nanomaterial MXene-Ti 3 C 2 preparation of

[0047] With the obtained Ti in step 1) 3 AlC 2 The ceramic powder is immersed in HF acid solution, in which 5g Ti 3 AlC 2 The powder was immersed in 100mL mass concentration of 40wt% HF acid solution for 48h; magnetic stirring, the ternary layered Ti 3 AlC 2 After the powder is corroded, it is centrifugally cleaned with deionized water until the pH is 5-6, and the obtained solid sample is dried at room tempe...

Embodiment 2

[0051] 1) Refined powder

[0052] Refinement of ternary layered Ti with a purity greater than 97% by high energy ball milling 3 AlC 2 Ceramic powder, ball milling condition: the mass ratio of ball stone, mixing material and ball milling medium (dehydrated alcohol) is 10:1:1, and ball milling speed is 400r / min, and the time of high-energy ball milling is 2h, then the gained solid-liquid mixture is in Dry at 50°C to obtain Ti with a particle size of about 56 μm 3 AlC 2 ceramic powder;

[0053] 2) Two-dimensional layered nanomaterial MXene-Ti 3 C 2 preparation of

[0054] With the obtained Ti in step 1) 3 AlC 2 The ceramic powder is immersed in the HF acid solution, in which 2gTi 3 AlC 2 The powder was immersed in 50mL mass concentration of 45wt% HF acid solution for 12h; magnetic stirring, the ternary layered Ti 3 AlC 2 After the powder is corroded, it is centrifugally cleaned with deionized water until the pH is 5-6, and the obtained solid sample is dried at room te...

Embodiment 3

[0058] 1) with embodiment 1 step 1);

[0059] 2) Two-dimensional layered nanomaterial MXene-Ti 3 C 2 preparation of

[0060] With the obtained Ti in step 1) 3 AlC 2 The ceramic powder is immersed in HF acid solution, in which 2g Ti 3 AlC 2 The powder was immersed in 50mL mass concentration of 45wt% HF acid solution for 6h; magnetic stirring, the ternary layered Ti 3 AlC 2 After the powder is corroded, it is centrifugally cleaned with deionized water until the pH is 5-6, and the obtained solid sample is dried at room temperature to obtain a two-dimensional layered nanomaterial MXene-Ti 3 C 2 ;

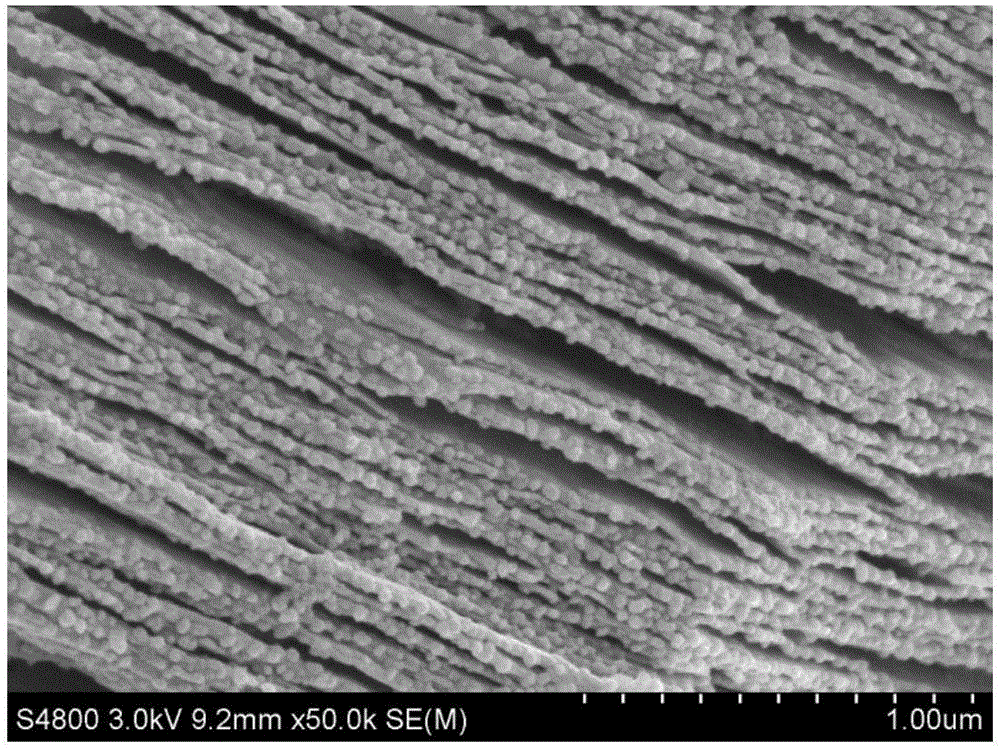

[0061] 3) Preparation of Ti by low temperature stirring method 3 C 2 / polyaniline composite material

[0062] Dissolve 0.15g oxalic acid in 80mL ultrapure water at room temperature, and the MXene-Ti obtained in step 2 3 C 2 Disperse 90 mg in the above solution and put it into an ultrasonic reactor for 1 h to form dispersed Ti 3 C 2 Mixed liquor; To the obtained dispers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com